Method for preparation of hydroxyethyl starch

A technology of hydroxyethyl starch and corn starch, applied in the field of medicine, can solve the problems of unqualified bacterial endotoxin in the product, easy growth of bacteria in the feed liquid, affecting production efficiency, etc., to avoid secondary pollution, easy filtration, and improved production efficiency. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

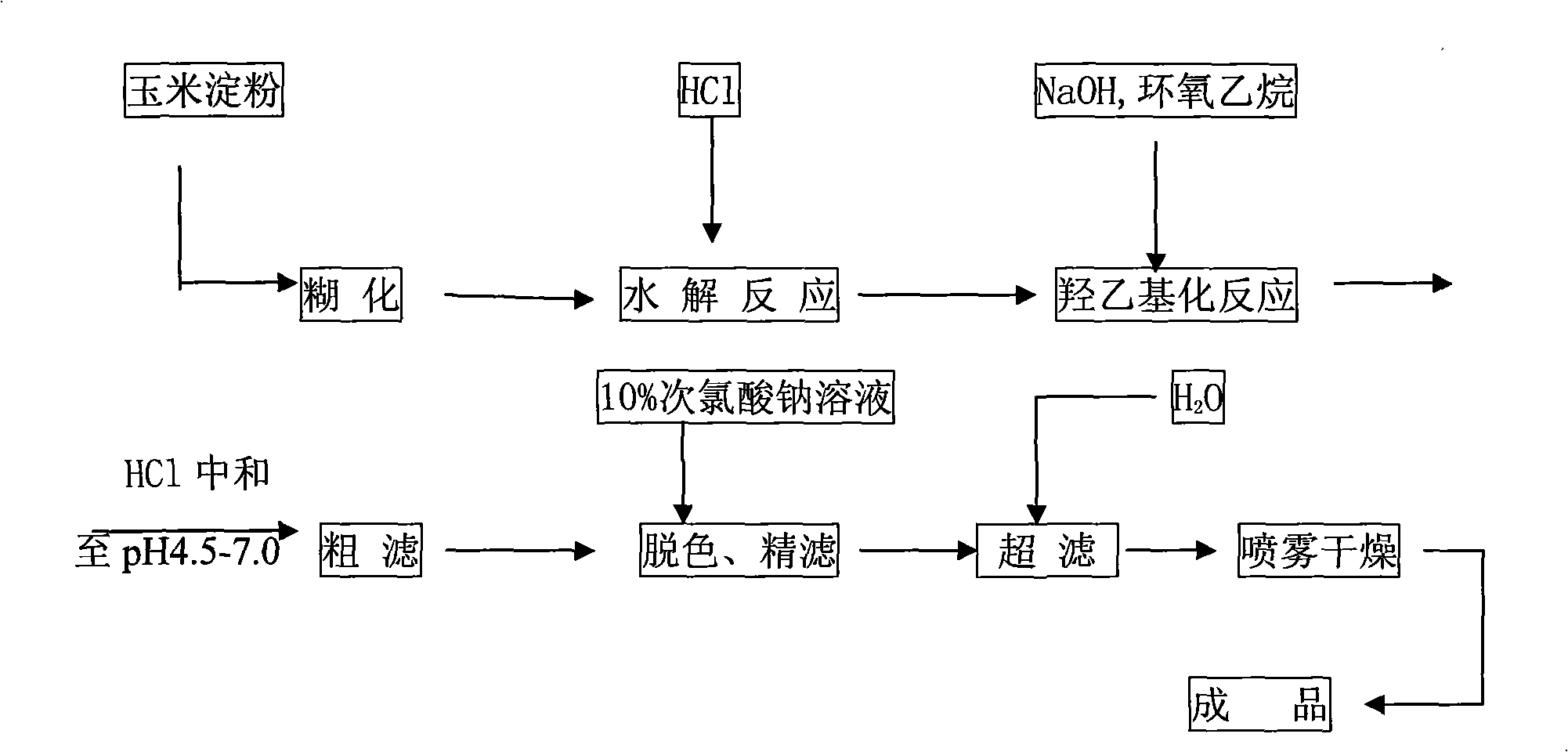

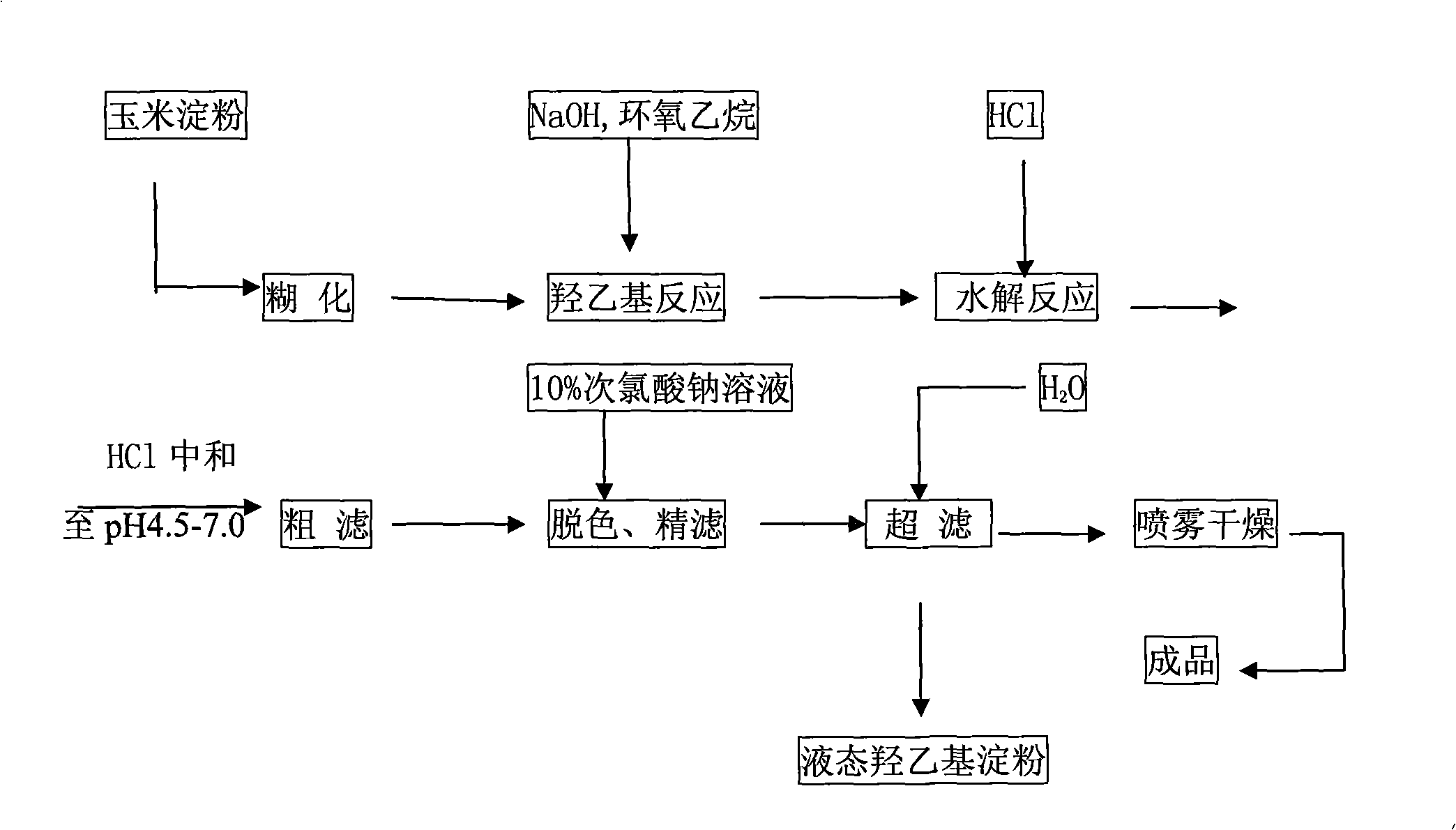

Method used

Image

Examples

experiment example 1

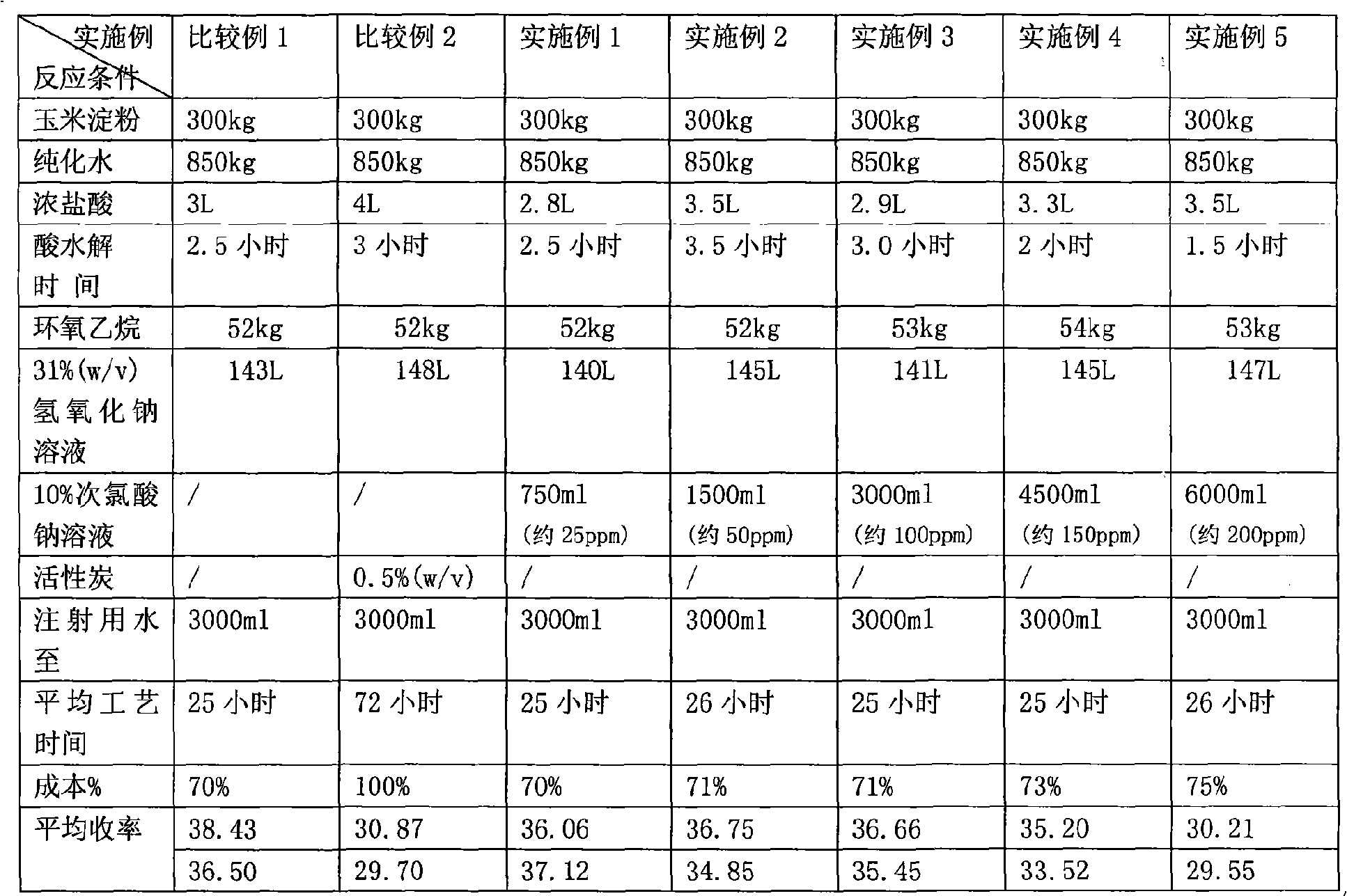

[0054] Experimental example 1. is to study specific examples 1, 2, 3, 4, 5 of the present invention and comparative example 1, 2 bacterial endotoxin

[0055] 1. Bacterial endotoxin inspection method Take this product and inspect according to the law (Appendix XI E of Part Two of the Chinese Pharmacopoeia 2005 Edition), the amount of endotoxin contained in each 1g should be less than 8.0EU.

[0056] Table 2. Bacterial endotoxin comparison results of specific examples 1, 2, 3, 4, 5 and comparative examples 1, 2

[0057]

[0058] 2. Experimental results: the above experiment shows that the applicable concentration range of 10% sodium hypochlorite solution is 50-200ppm. Experimental example 2. is to study the character of specific embodiment of the present invention and comparative example

experiment example 2

[0058] 2. Experimental results: the above experiment shows that the applicable concentration range of 10% sodium hypochlorite solution is 50-200ppm. Experimental example 2. is to study the character of specific embodiment of the present invention and comparative example

[0059] 1. Character inspection: visual inspection (the 2005 edition of Chinese Pharmacopoeia stipulates the color and appearance of the drug)

[0060] 2. Standard: The national drug standard of this product is white or off-white powder

[0061] Table 3. The character comparative result of specific embodiment 1,2,3,4,5 and comparative example 1,2

[0062]

[0063] 3. Results: The color of Comparative Example 1 and Example 1 does not meet the standard requirements, and the color of the remaining examples is off-white or white and meets the standard requirements.

[0064] Post-acid hydrolysis embodiment as attached figure 2 As shown, 300kg of medical grade cornstarch, add 850kg of purified water, boil, ke...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Specific rotation | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com