Irradiation treatment method for vinyl cyanide wastewater

A technology of acrylonitrile wastewater and its treatment method, which is applied in natural water treatment, light water/sewage treatment, water/sludge/sewage treatment, etc. It can solve the problems of unsatisfactory treatment effect, less industrial application, and high treatment cost. Achieve the effect of great practical value, low cost and simple processing equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0016] 1 Take three parts of 10mL acrylonitrile waste water prepared by yourself with a concentration of 1000mg / L, add it into a radiation-resistant glass container, and place it in the central channel for irradiation treatment;

[0017] 2 waste water through γ- 60 After treatment with 10, 15, and 20 kGy irradiation doses provided by the Co source, the acrylonitrile polymer precipitate was separated from the water phase by filtration.

[0018] 3 Use pyridine colorimetry to measure the residual acrylonitrile content, and then calculate the removal rate of acrylonitrile.

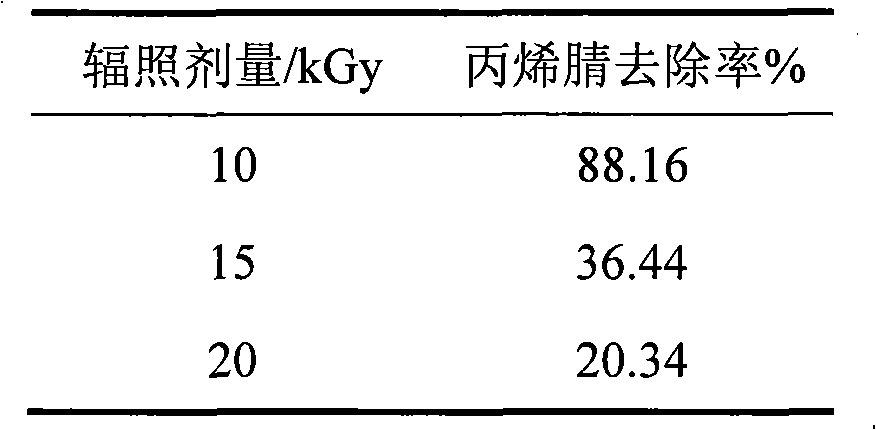

[0019] Table 1 shows the treatment effects of different irradiation doses on acrylonitrile wastewater with a concentration of 1000 mg / L. It can be seen from Table 1 that the removal rate of acrylonitrile is higher when the irradiation dose is 10kGy.

[0020] The treatment effect of the acrylonitrile waste water that concentration is 1000mg / L under the different irradiation doses of table 1

[0021]

Embodiment 2

[0023] 1 Take three 10mL parts of acrylonitrile wastewater with a concentration of 4000mg / L and adjust the initial pH values of the wastewater to 4.0, 7.0 and 11.0 respectively;

[0024] 2. Add it to the radiation-resistant glass container and place it in the central channel for radiation treatment;

[0025] 3 waste water through γ- 60 The Co source provided 10kGy and 15kGy of radiation dose treatment, and the acrylonitrile polymer precipitate was separated from the water phase by filtration.

[0026] 4 Measure the concentration of residual acrylonitrile by pyridine colorimetry, and then calculate the removal rate of acrylonitrile.

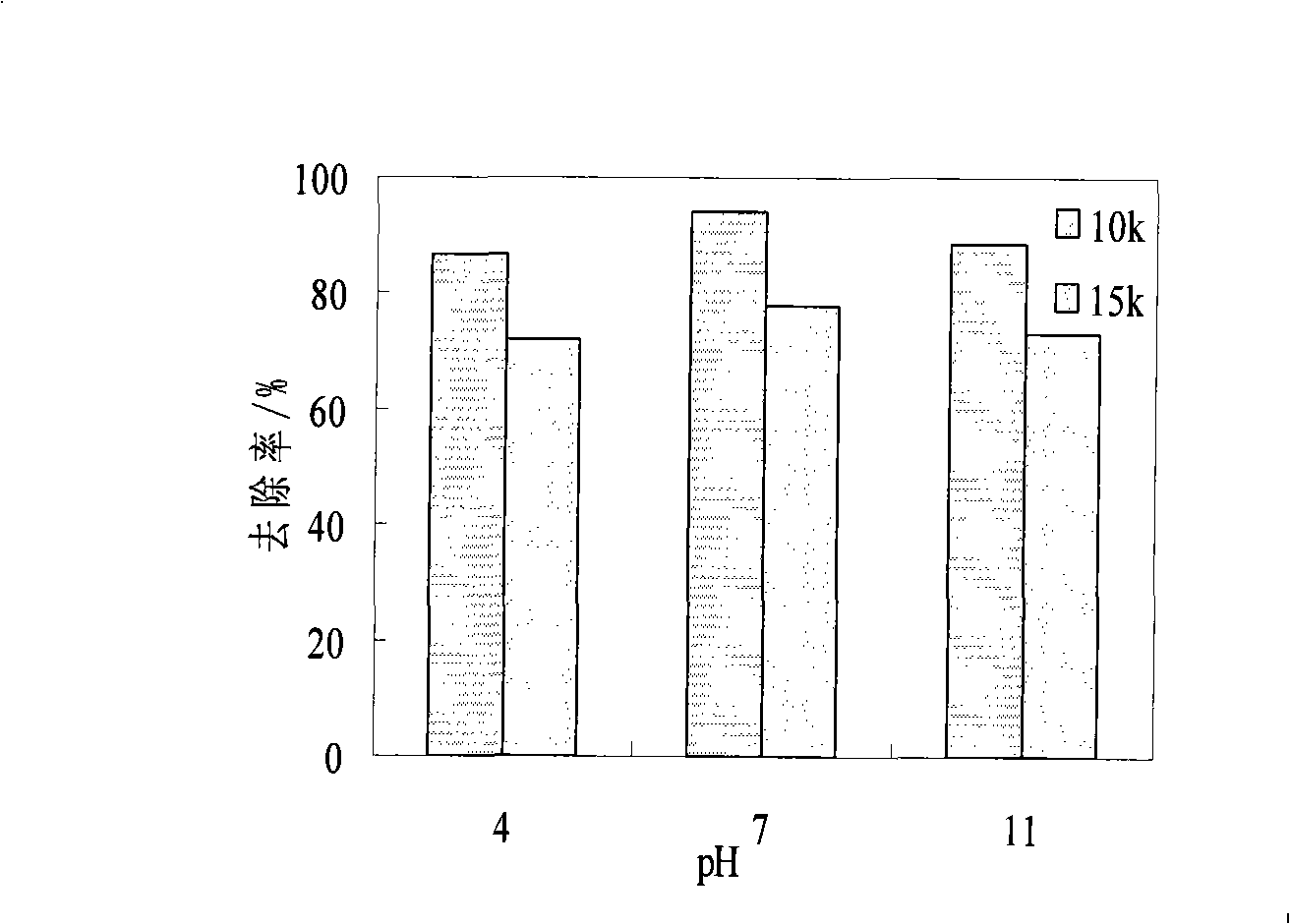

[0027] figure 1 The results show that when the initial pH value of acrylonitrile wastewater is between 4.0 and 11.0, radiation treatment has little effect on the removal rate of acrylonitrile. Therefore, for actual acrylonitrile wastewater, radiation treatment can be directly carried out without adjusting its pH value, which simplifies the pr...

Embodiment 3

[0029] 1 Take four 10mL parts of acrylonitrile wastewater with a concentration of 4000mg / L and add it into a radiation-resistant glass container, and place it in the central channel for irradiation treatment;

[0030] 2 waste water through γ- 60 After treatment with 3kGy, 5kGy, 10kGy and 15kGy irradiation doses provided by the Co source, the acrylonitrile polymer precipitate was separated from the aqueous phase by filtration.

[0031] 3 Use pyridine colorimetric method to measure residual acrylonitrile concentration, and then calculate the removal rate of acrylonitrile in wastewater under different irradiation doses.

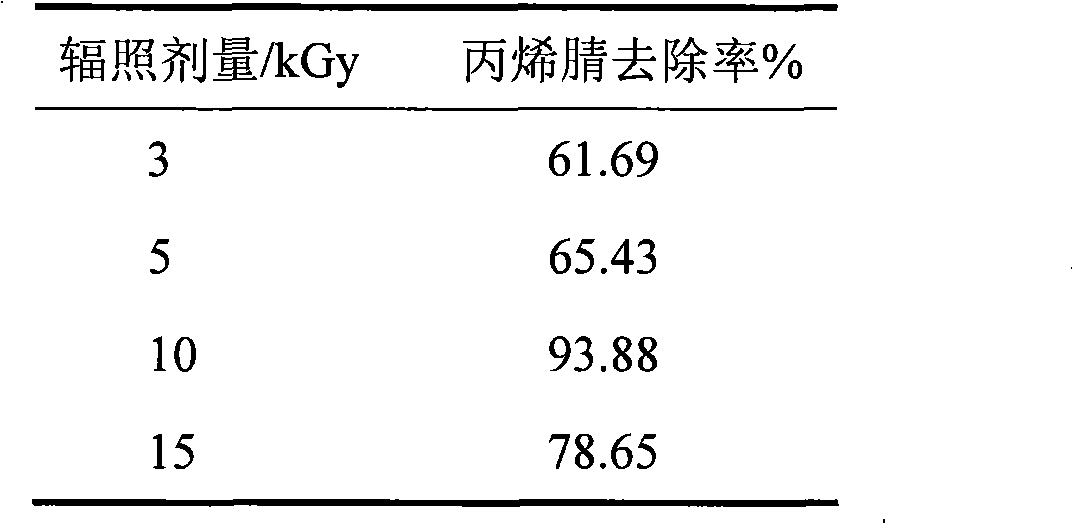

[0032] Table 2 shows the removal rate of acrylonitrile under different irradiation doses when the concentration of acrylonitrile wastewater is 4000mg / L. From the data in the table, it can be known that the preferred irradiation dose of acrylonitrile wastewater with this concentration is 10-15kGy.

[0033] The treatment effect of acrylonitrile wastewater with a ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com