Livestock and poultry raising sewage disposal process and disposal system thereof

A sewage treatment system, livestock and poultry breeding technology, applied in the field of livestock and poultry breeding sewage treatment process and its treatment system, can solve the problems of poor selectivity of heavy metals, non-compliance, secondary pollution of sediments, etc., to reduce organic load and balance hydraulic power Loading, reducing the effect of organic concentration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

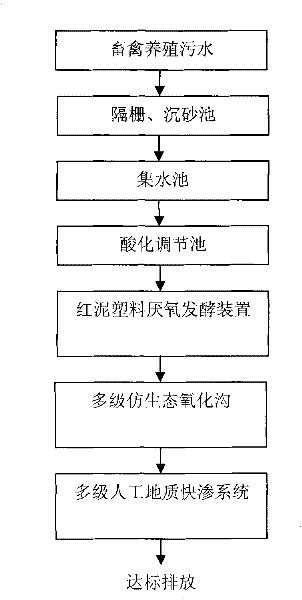

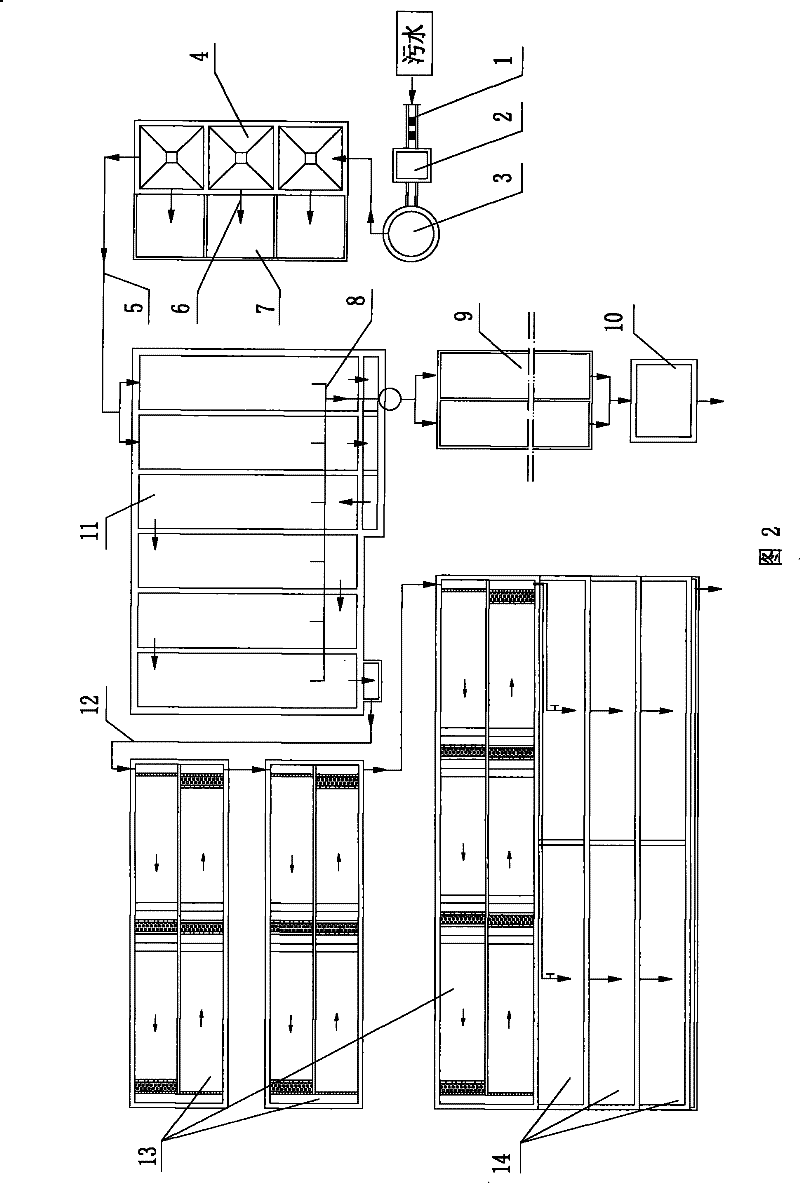

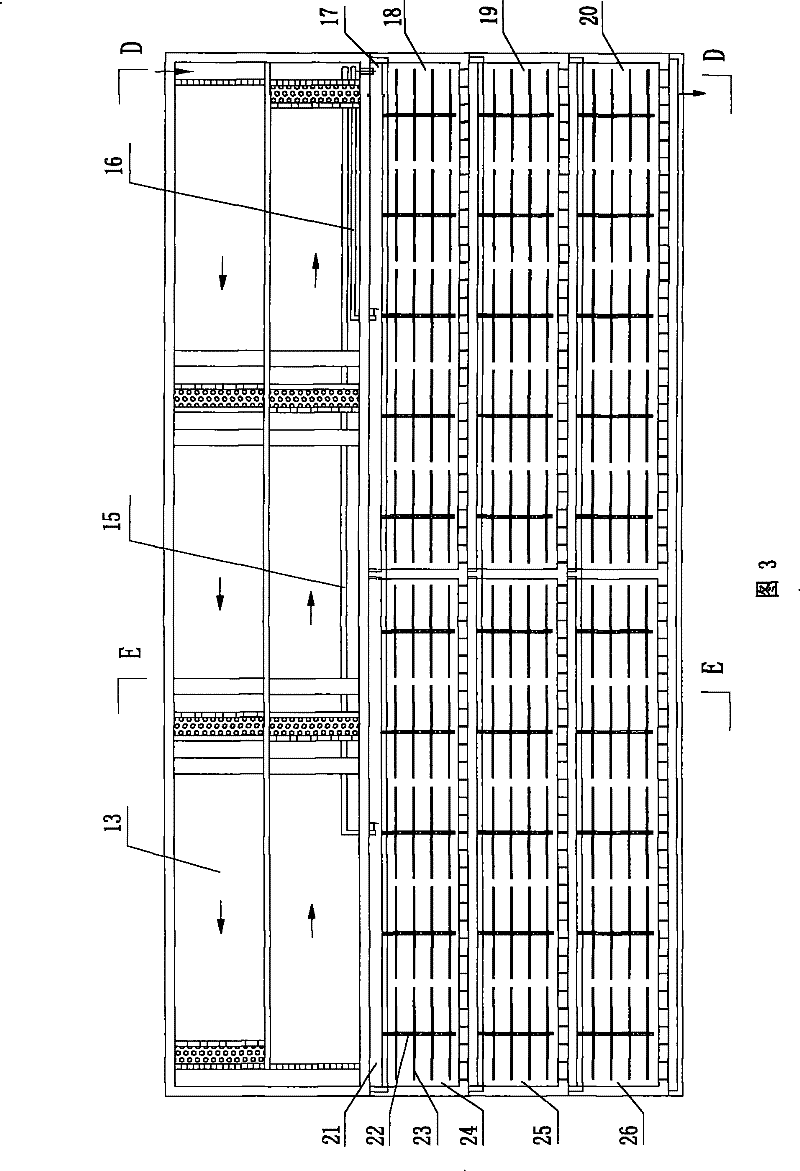

[0032] Such as figure 1 , figure 2 Shown, livestock and poultry breeding sewage treatment process, it comprises the following steps:

[0033] 1) Sewage pre-treatment: The sewage from livestock and poultry breeding flows into the drainage ditch after being discharged, and after removing sundries (long fibers, wool, etc.) through the grille in the drainage ditch, it enters the grit chamber for sedimentation; The solids (such as dung, sediment, scum and other large solids, which are deposited in the grit chamber) enter the sump; the sewage is mixed evenly in the sump and then enters the acidification adjustment tank, and the organic matter and macromolecular substances are in the acidification tank Under the action of acid-producing bacteria, it is acidified and hydrolyzed (no need to add acid to adjust the pH value in this link), to prepare for the subsequent biogas production in the anaerobic tank, and then to remove insoluble pollutants in the sewage by sedimentation, and to...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com