Smoothing and/or lapping tool particularly for finishing stone materials

A technology for tools and grinding materials, applied in the field of polishing natural or artificial stone, ceramics or similar materials, which can solve the problems of material formation defects, affecting production costs, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

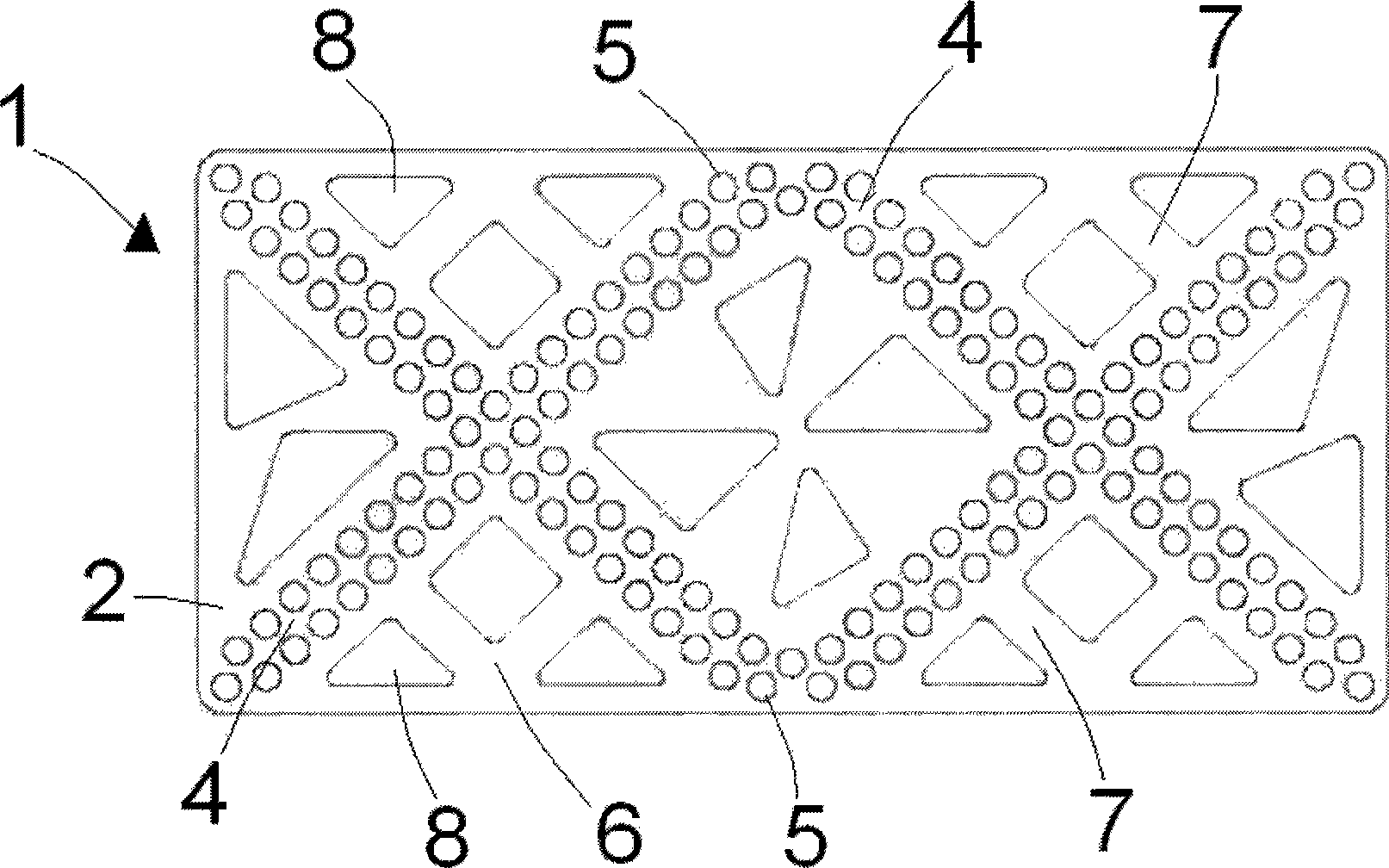

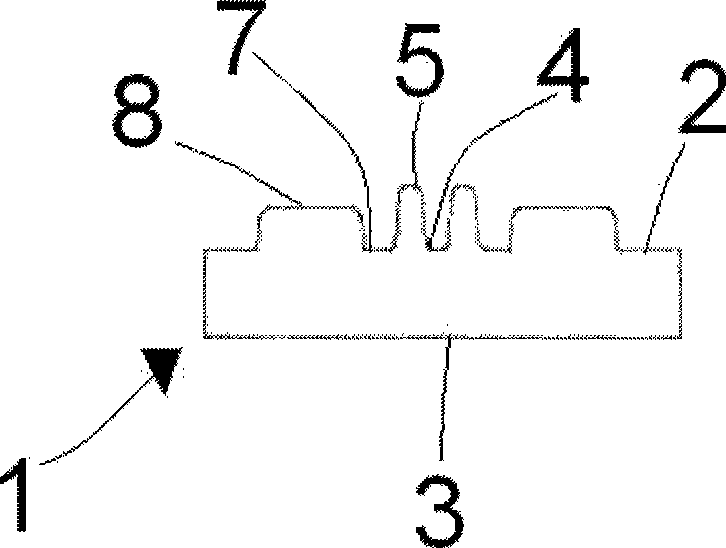

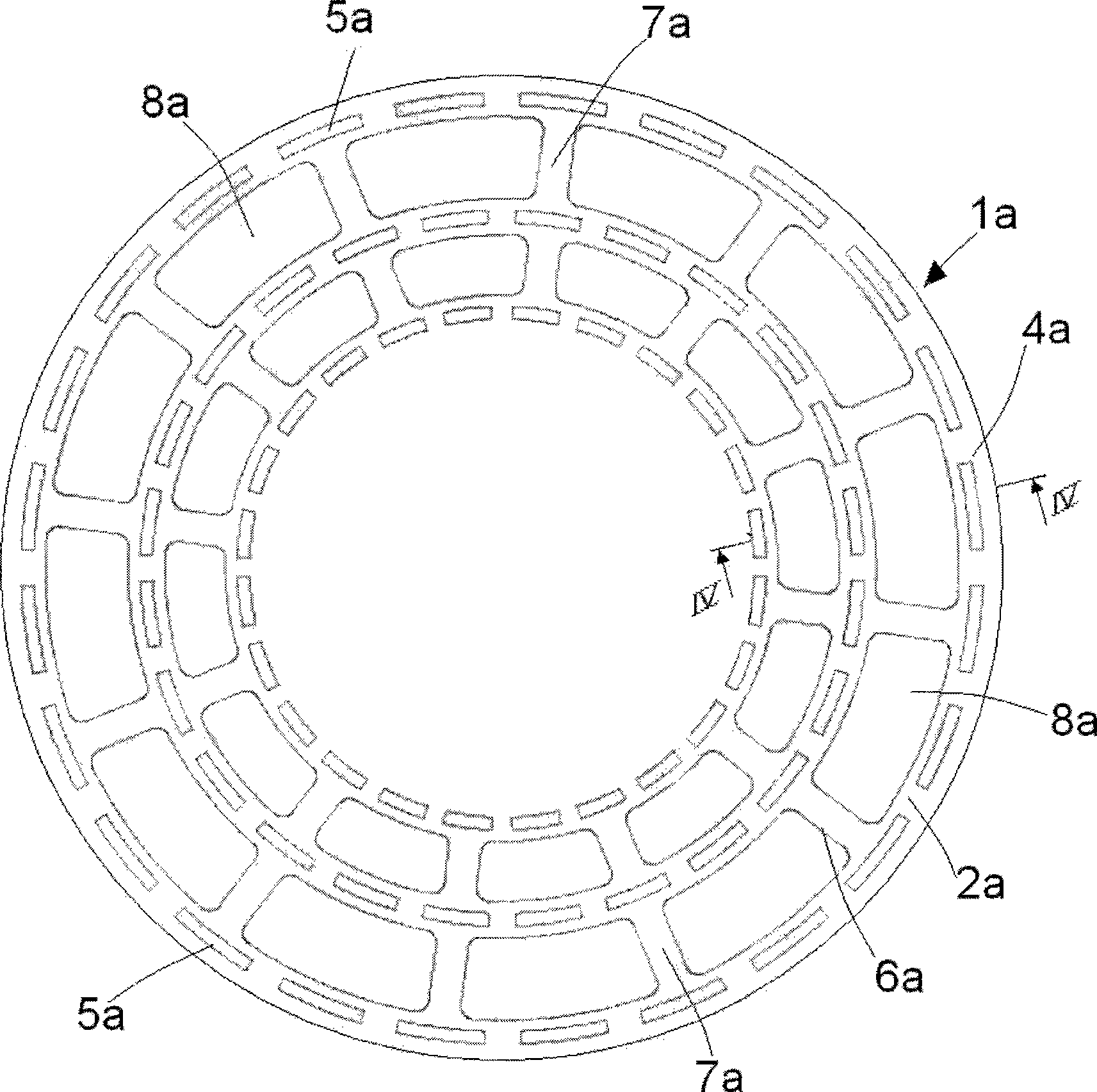

[0015] first reference figure 1 with 2 As shown in the figure, the polishing and / or smoothing tool 1 of the first embodiment of the present invention is a parallelepiped block-shaped abrasive material as a whole. The block 1 comprises a front working part 2 and a rear part 3 . The rear portion may be in the shape of a handle for manual use, or as a horseshoe for securing the tool to the table of a honing or polishing machine (not shown), as is known in the art.

[0016] The front working part 2 comprises one or more brush working areas 4 with a plurality of bristle parts 5 protruding or protruding from the rear fixed part or handle 3 with a length greater than the maximum thickness or lateral direction of each bristle part 5 Many times larger in size (typically from 5 to 10 times). Advantageously, the brush working parts are arranged at intervals and extend, extending through the length direction of the front working part 2, preferably also in the width direction, thereby d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com