Flux-cored wire

A technology of flux-cored welding wire and welding wire, which is applied in welding medium, welding equipment, welding/cutting medium/material, etc., can solve the problems of no one proposed specific plan, reduced usage ratio, low workability of solid core welding wire, etc., and achieves excellent performance. The effect of welding workability, high temperature crack resistance, good tensile strength and impact toughness of weld metal

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example

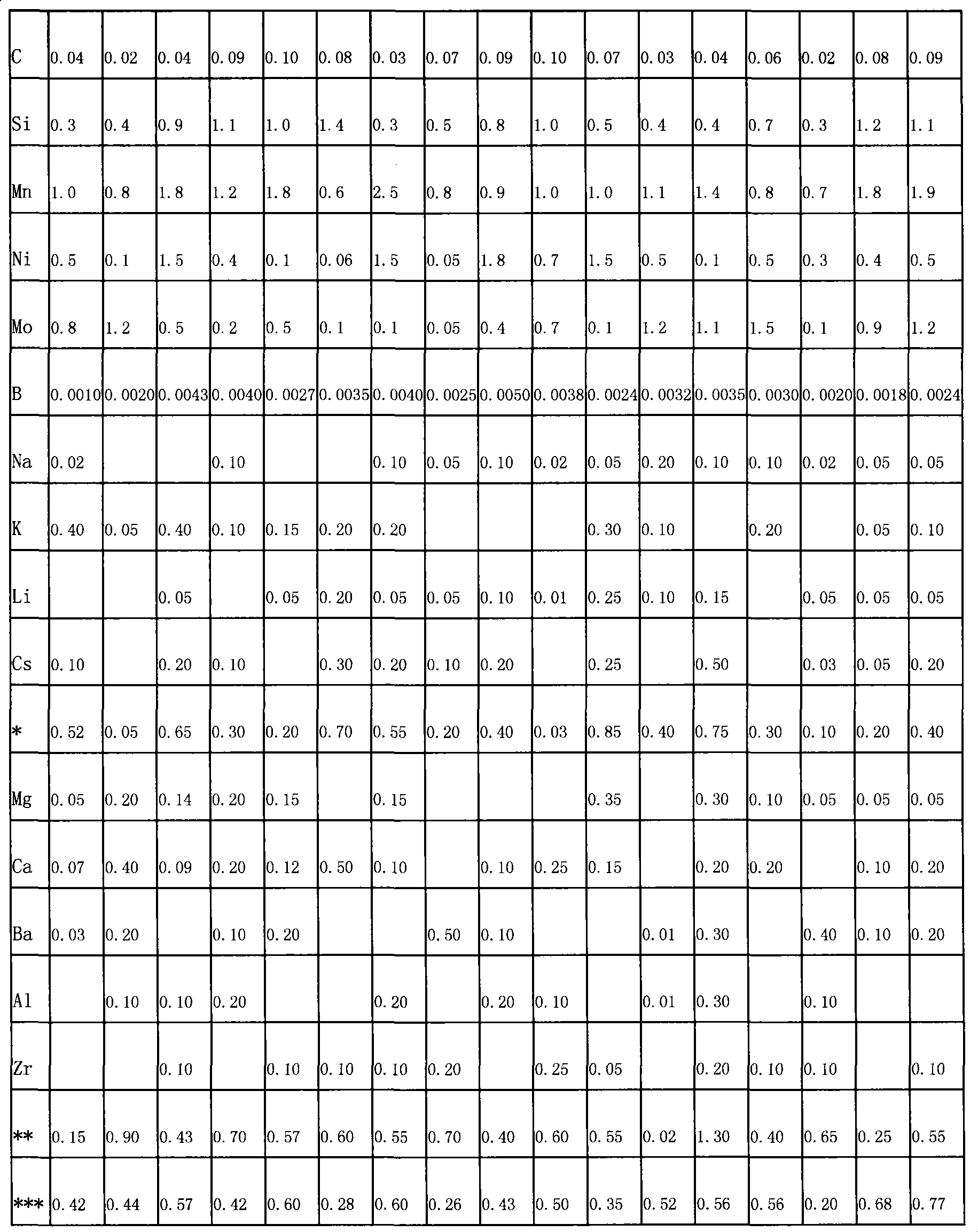

[0046] Prepare gas-shielded arc welding powder-cored welding wire with a diameter of 1.4 mm in advance according to the contents in Table 1 below. At this time, the powder filling rate is 15-20%, and the composition content of the powder used is the weight percentage of the total weight of the welding wire, and it is recorded in Table 2.

[0047]【Table 1】

[0048]

[0049]

[0050] * is the sum of one or two or more substances selected from Na, K, Li and Cs.

[0051] ** is the sum of one or two or more substances selected from Mg, Ca, Ba, Al and Zr.

[0052] *** is C+Si / 25+Mn / 5+Ni / 40+Mo / 5

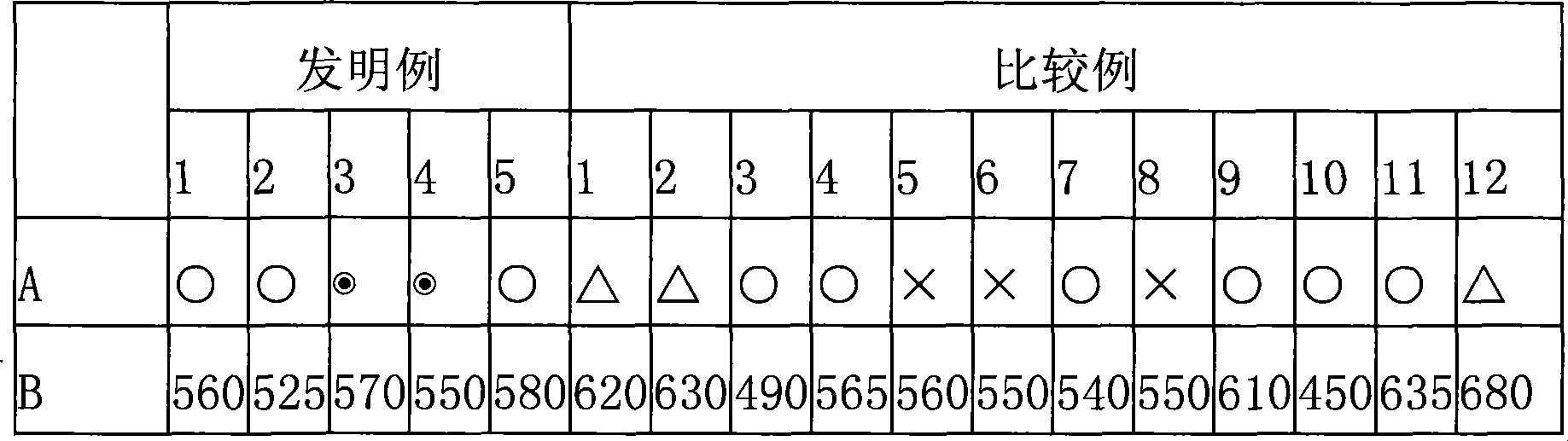

[0053] 【Table 2】

[0054] Classification C Si mn P S Fe content 0.025 0.0025 0.21 0.009 0.01 remnant

[0055] Using the above welding wire, the SM520B welding mother with a thickness of 25mm was welded, and the specific welding conditions are shown in Table 3. After welding, the welding workability, mechanical properties and high-temperature crac...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com