Roller aerosol cooling method and device

A cooling method and cooling device technology, applied in the direction of rolls, metal rolling, metal rolling, etc., can solve the problem of no air mist cooling rolls reported in hot rolling mills, difficulty in ensuring the final rolling temperature of webs, and H-shaped steel webs Serious temperature drop and other problems, to achieve the effect of reducing cooling water consumption, increasing service life, and improving performance quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

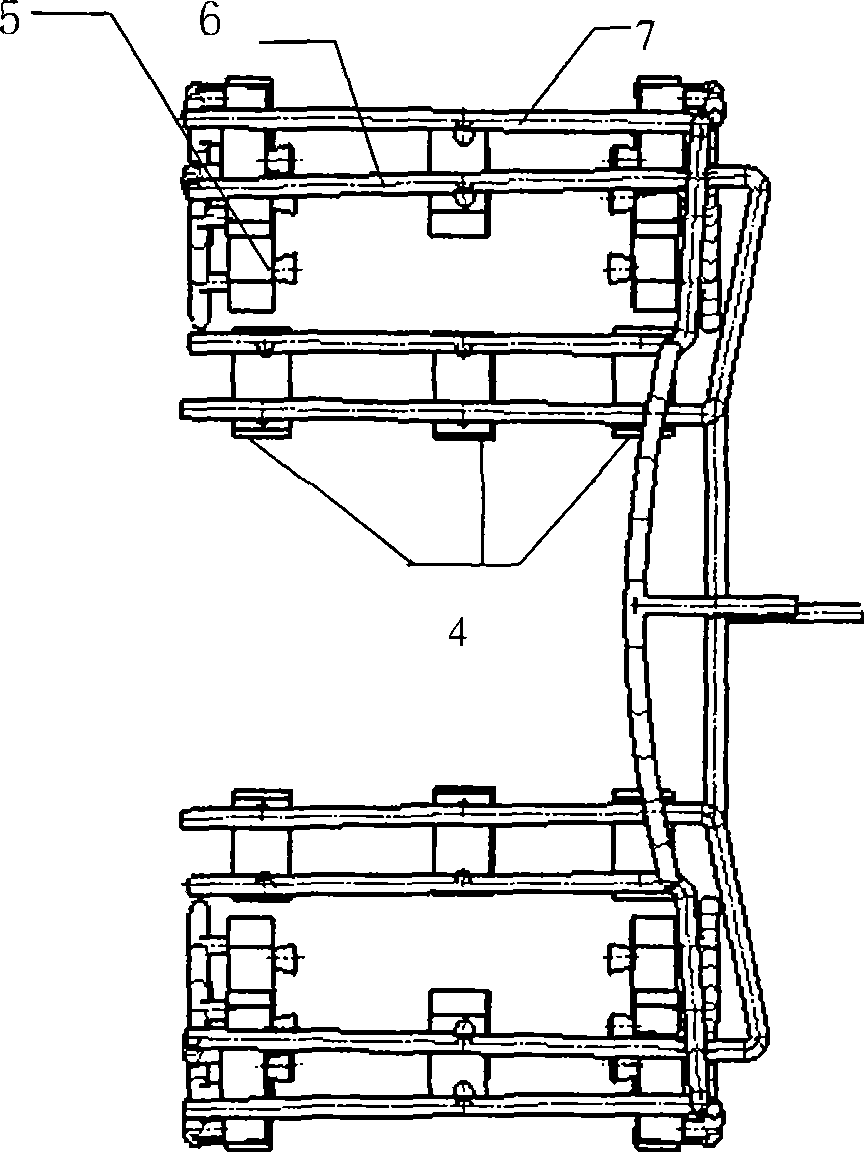

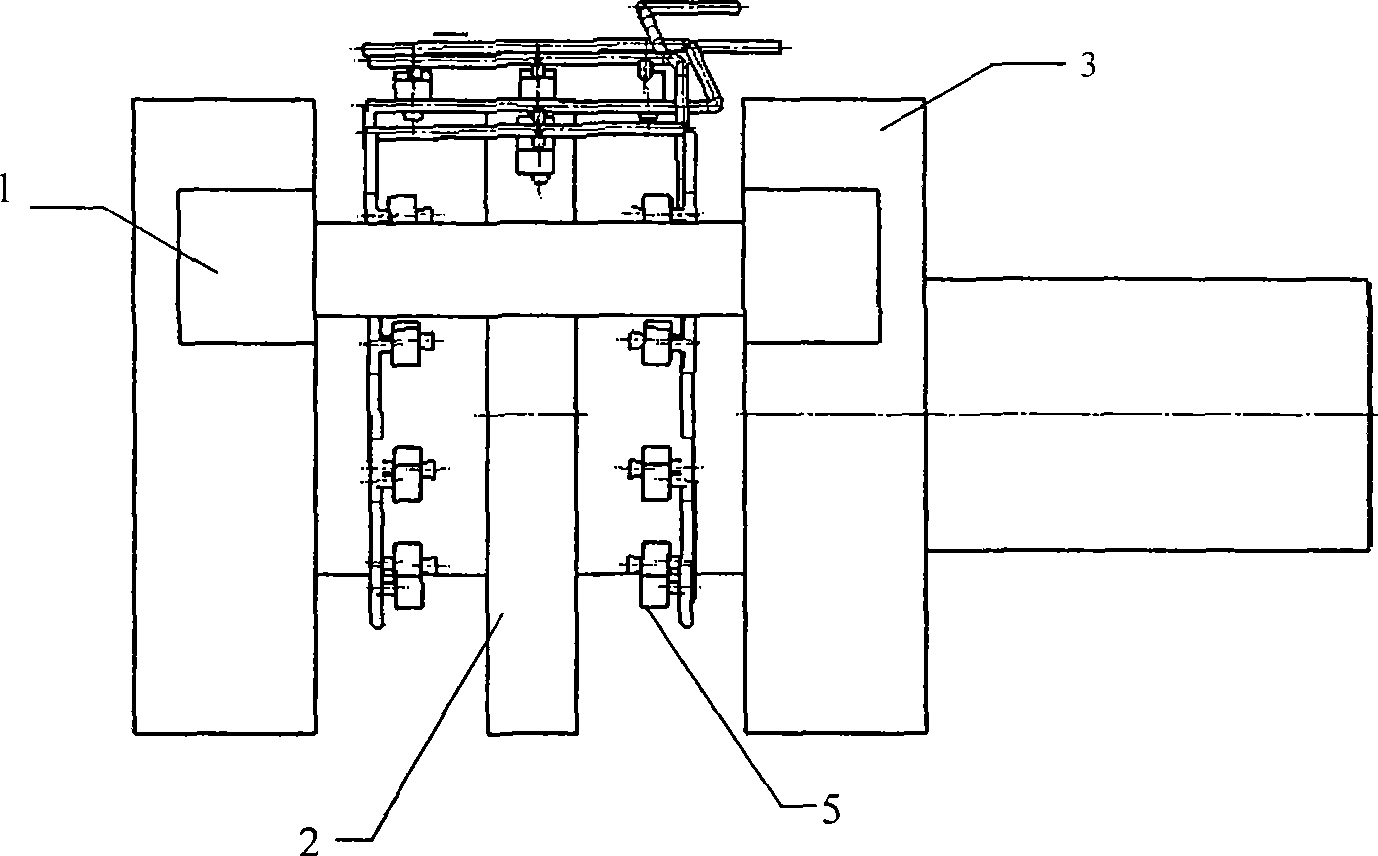

[0027] A roll mist cooling method and device, the structure of the device is as follows figure 1 and soil as shown.

[0028] The roll steam mist cooling method is as follows: the high-pressure cooling water and the high-pressure gas are sent to the top of the roll through the high-pressure cooling water pipeline and the compressed air pipeline respectively, and the high-pressure gas in the compressed air pipeline converts the high-pressure cooling water into a mixed high-pressure The steam mist is sprayed from the nozzles, and the steam mist is sprayed on the roll in a fan shape. Three nozzles form a nozzle cooling surface, and the spray angle is 45°~140°; the high-pressure steam mist is sprayed onto the roll through multiple groups of nozzle cooling surfaces. Realize the cooling of the roll.

[0029] The high-pressure cooling water is industrial water with a pressure of 0.4-0.8 MPa and a temperature of 0-28° C. or demineralized water after treatment.

[0030] The high-press...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com