Polypropylene resin composition and molded articles, sheet or container therefrom

A technology of polypropylene resin and propylene polymer, applied in containers, rigid containers, applications, etc., can solve the problems of inability to obtain heat resistance, achieve excellent transparency, excellent heat resistance, and inhibit the occurrence of whitening

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0107]

[0108] Using a Henschel mixer, the propylene polymer (A) and the propylene-1-butene random copolymer (B) were dry-blended according to the compounding amounts described in Table 1, and the obtained polypropylene resin composition was prepared with T -The extruder of the die was formed into a film at an extrusion temperature of 210° C. and a chill roll temperature of 30° C. to obtain a sheet having a thickness of 0.6 mm.

[0109]

[0110] Using a vacuum forming machine with a cup-shaped metal mold with a diameter of 80mm and a depth of 40mm, under the conditions of a preheating heater temperature of 250°C, a preheating time of 15 seconds, a mold temperature of 20°C, and a holding time in the mold of 10 seconds, use The sheet obtained above was subjected to vacuum forming.

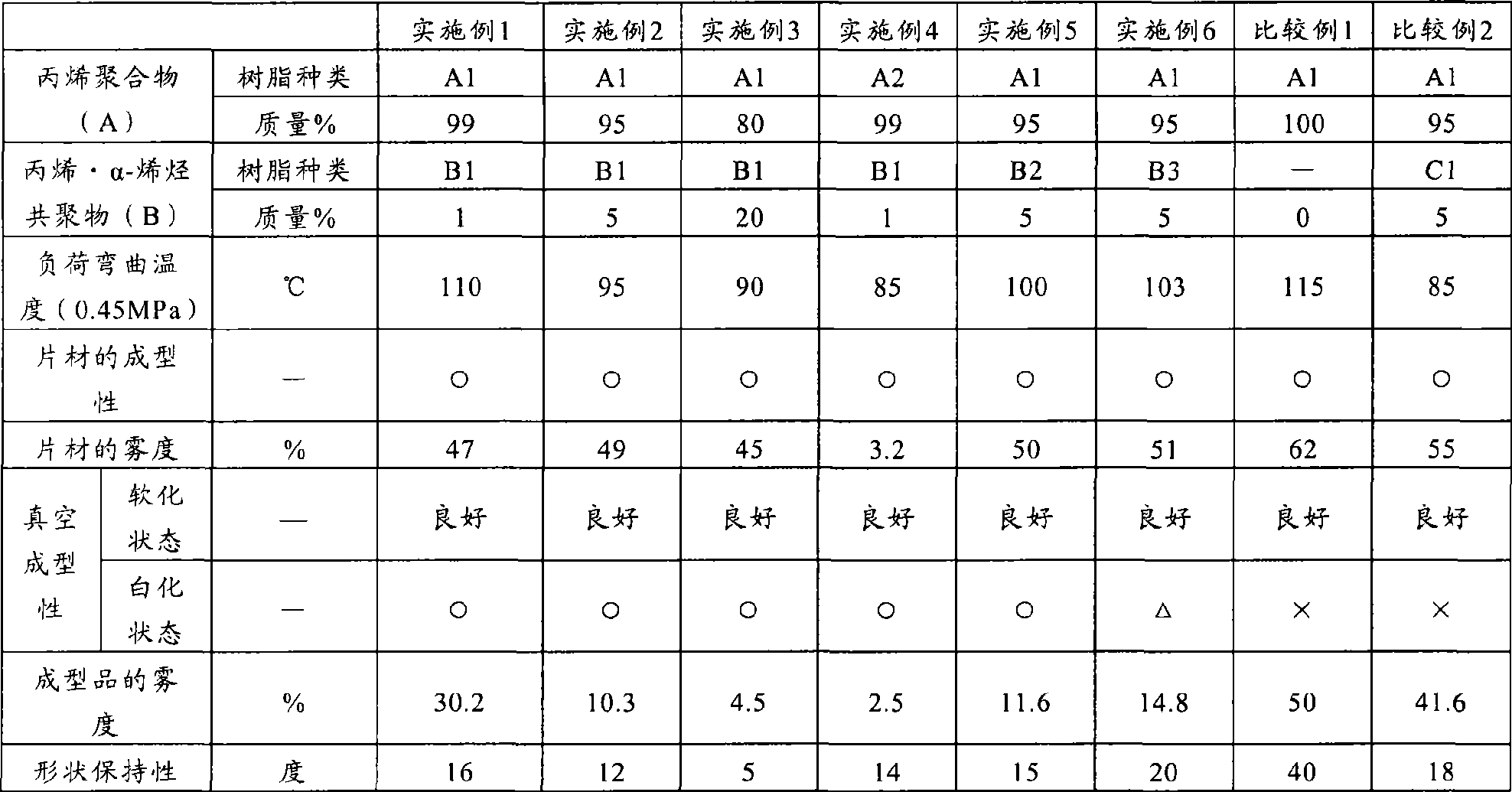

[0111] As heat resistance, the evaluation results of deflection temperature under load measured with a test piece, formability of the sheet, haze of the sheet, vacuum formability (softened state...

Embodiment 2、3

[0114] [Example 2, 3, Comparative Example 1]

[0115] A sheet was obtained in the same manner as in Example 1 except that the compounding ratio of the propylene polymer (A) and the propylene / 1-butene random copolymer (B) was the composition described in Table 1.

[0116] Next, vacuum forming and bending were performed using the obtained sheet.

[0117] Physical properties were evaluated in the same manner as in Example 1, and the results are shown in Table 1.

Embodiment 4

[0119] Except having used (A2) as a propylene polymer (A), it carried out similarly to Example 1, and obtained the sheet.

[0120] Next, vacuum forming and bending were performed using the obtained sheet.

[0121] Physical properties were evaluated in the same manner as in Example 1, and the results are shown in Table 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com