Coated steel sheet, works, panels for thin televisions and process for production of coated steel sheet

A technology for coating steel plates and steel plates, applied in the direction of metal material coating process, coating, layered products, etc., can solve the problems of unoptimized environment, no consideration, and insufficient stamping workability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

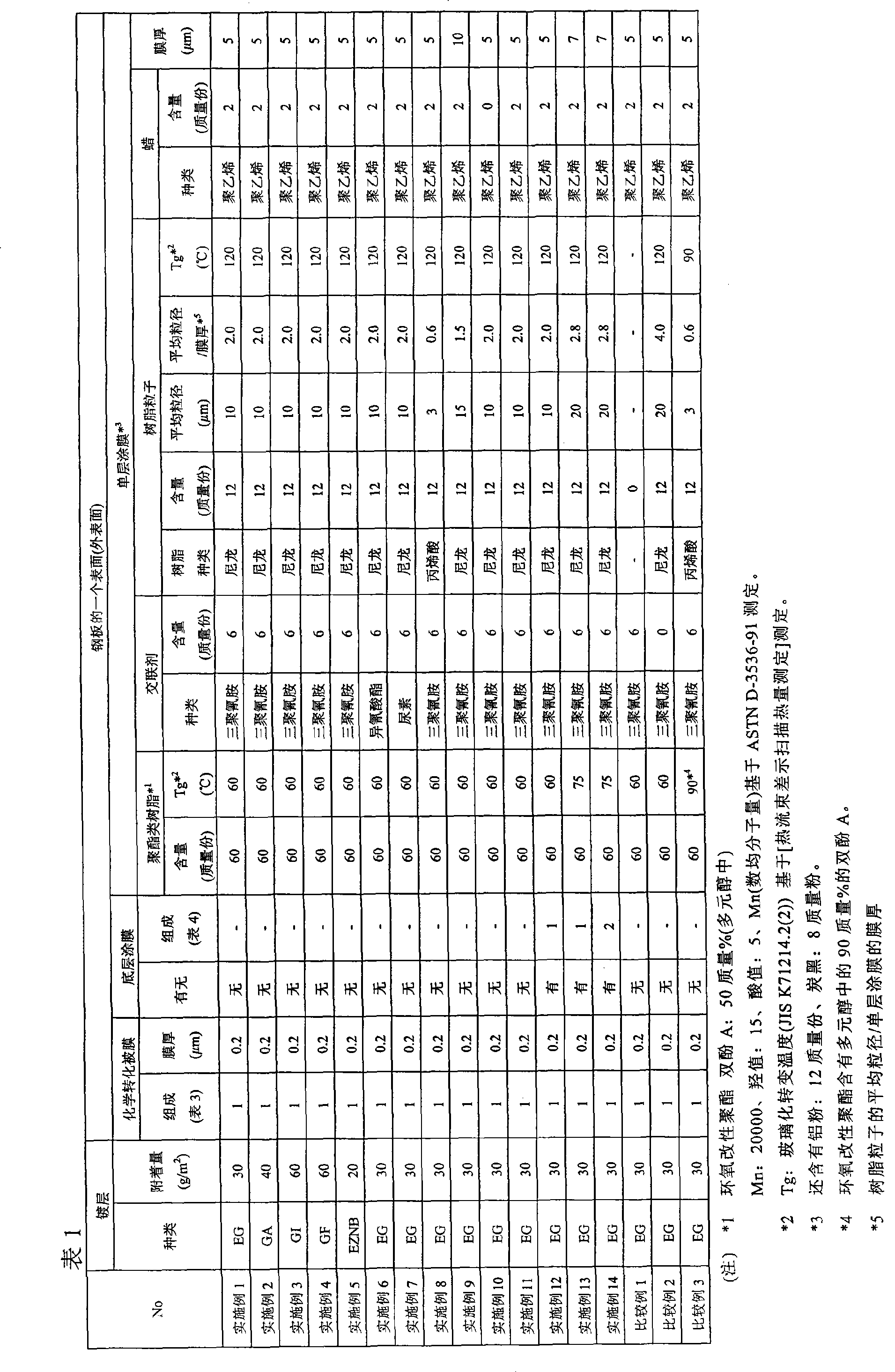

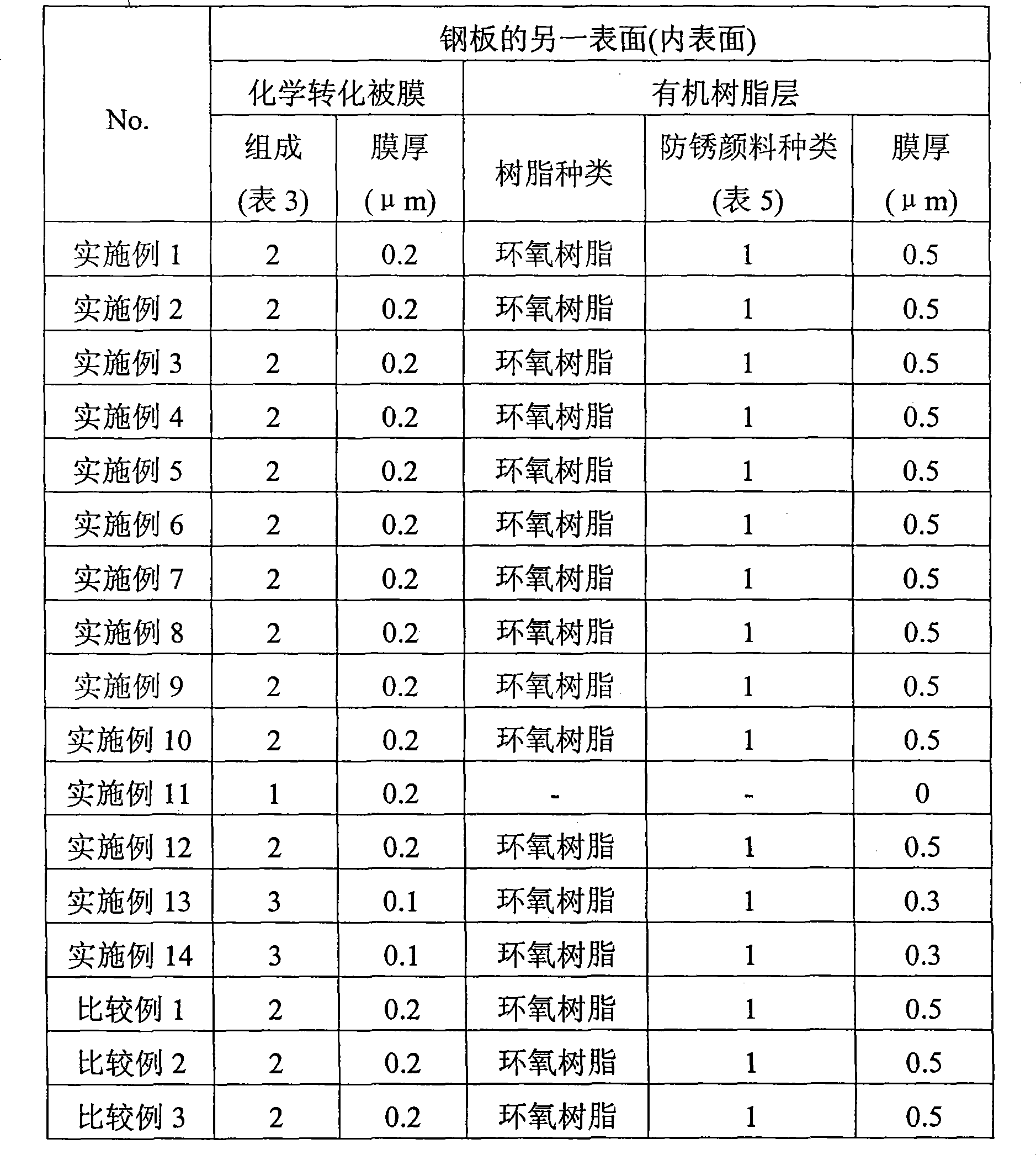

[0088] Examples of the present invention will be described.

[0089] As galvanized steel sheets for coating, electro-galvanized steel sheets (coating type code: EG) with a thickness of 0.5 mm, alloyed hot-dip galvanized steel sheets (Fe content: 10% by mass, coating type code: GA), and hot-dip galvanized steel sheets (coating type code: GA) with a thickness of 0.5 mm were prepared. Galvanized steel sheet (coating type code: GI), hot-dip Zn-Al steel sheet (Al content: 4.5% by mass, coating type code: GF) and black electroplated zinc-nickel alloy steel sheet (Ni content: 12% by mass, coating Species designation: EZNB). The coating adhesion amount of the coated steel sheet is shown in Table 1. In addition, the deposition amount and composition of the plating layer on one surface (outer surface) and the other surface (inner surface) of the steel sheet were made the same. After degreasing the prepared coated steel sheet, the following processes (i) to (iv) were performed to produ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com