Digital printed applique emblem

A digital printing and printing technology, applied in printing, post-processing of printing, dyeing, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

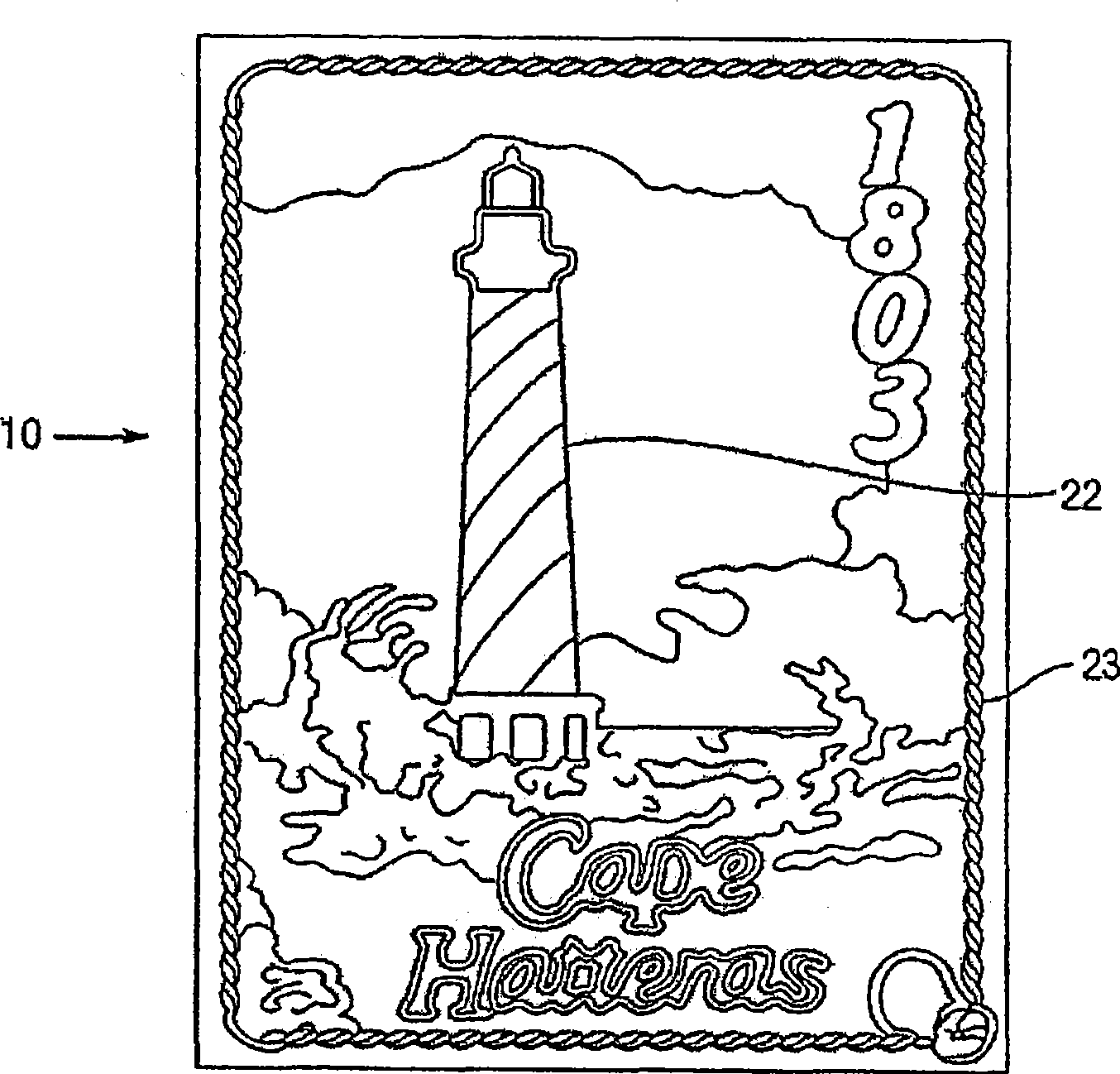

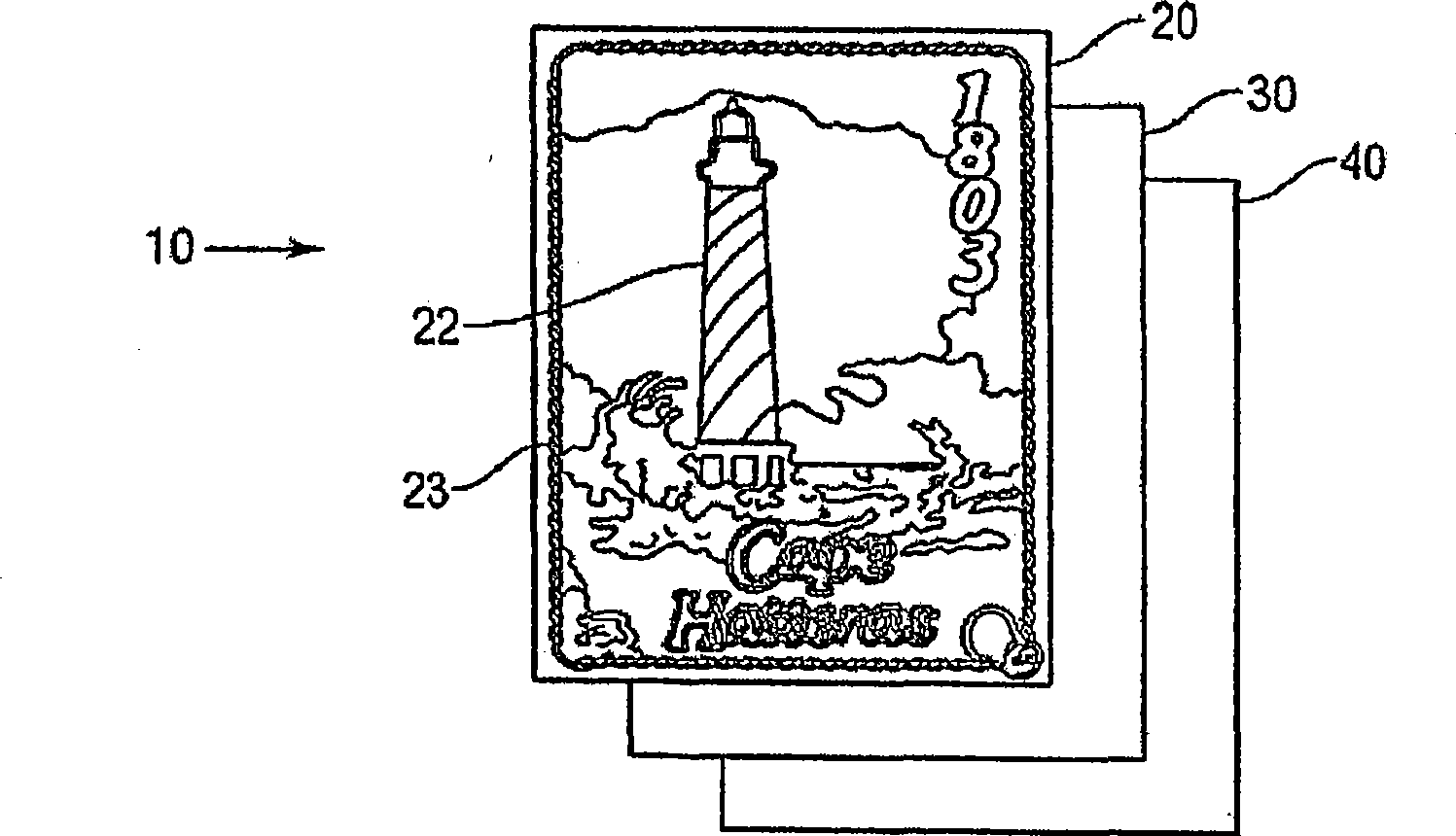

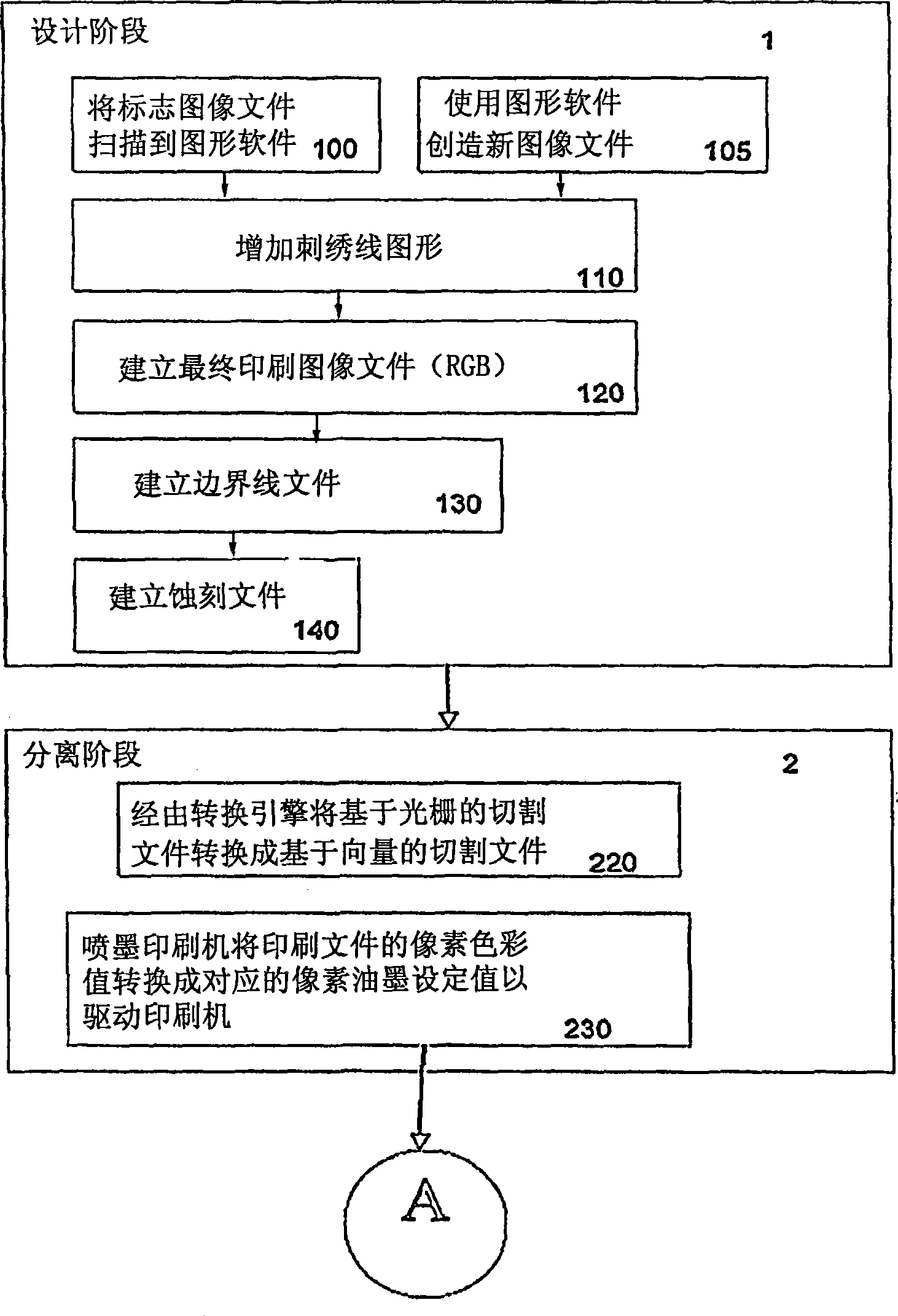

[0029] The present invention relates to an adhesive printed transfer badge with text, numbers, logos and other indicia for uniform and other industries, and methods for efficiently mass producing the transfer badge using digital printing, etching and / or cutting techniques novel approach. Emblems include a colorful printed design look with or without simulated and / or textured embroidery threads and can be heat sealed to a garment or garment accessory. In all cases, badges are well suited for application to any fabric or leather substrate, including coarser non-woven fabrics such as felt and wool ("non-woven" here is defined as produced by processes other than weaving) any fabric base layer). Suitability for a particular fabric depends on the particular heat-sealable thermoplastic film used, and as described below, different films may be used for different fabrics.

[0030] figure 1 is a perspective view of an exemplary emblem 10 according to the present invention as it appea...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com