Regeneration method for waste lithium ion phosphate positive pole material

A positive electrode material, lithium iron phosphate technology, applied in the field of regeneration of lithium iron phosphate positive electrode material waste, can solve environmental pollution, increase battery production costs and other issues, achieve low cost, avoid improper handling, and reduce overall costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

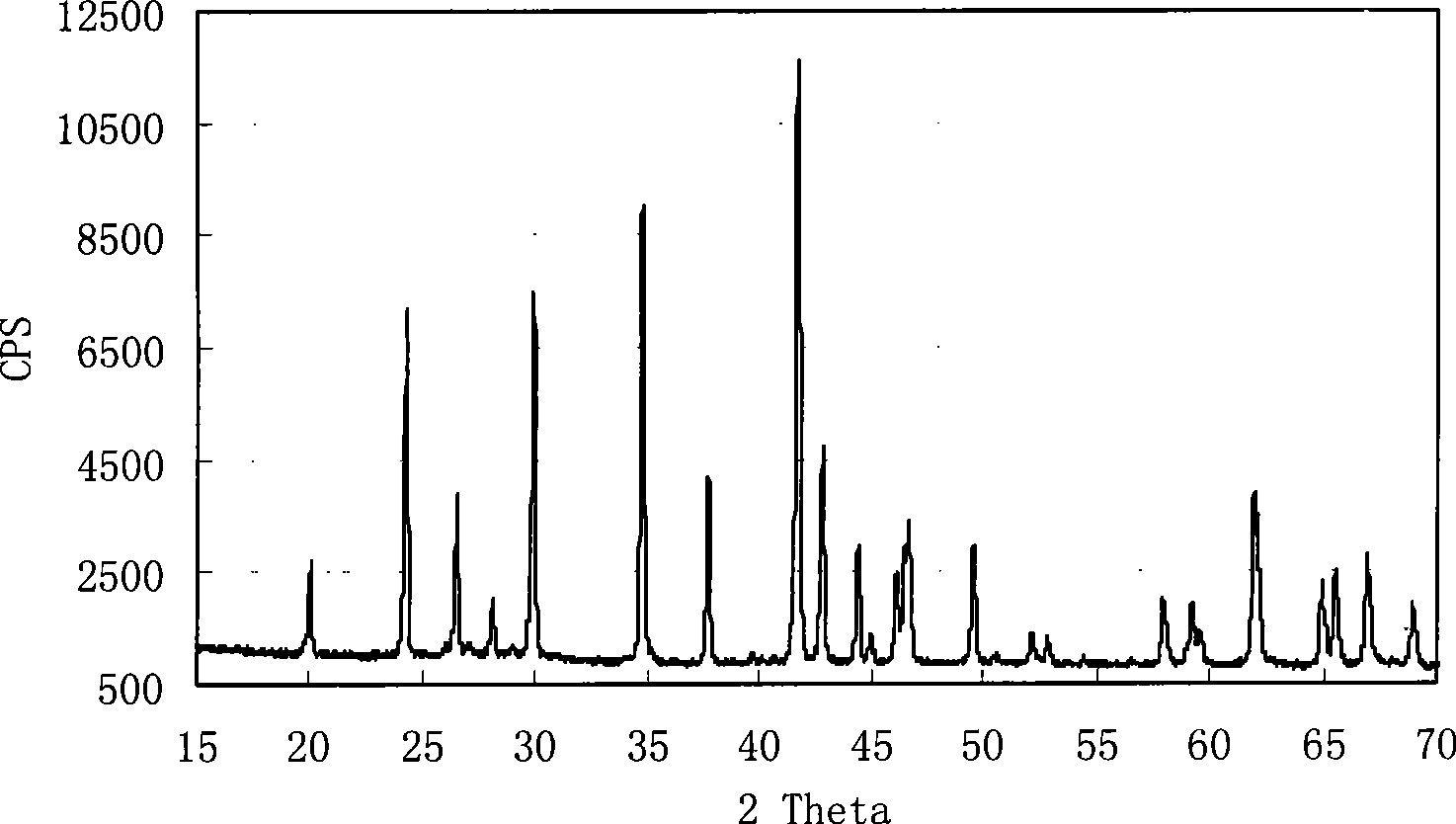

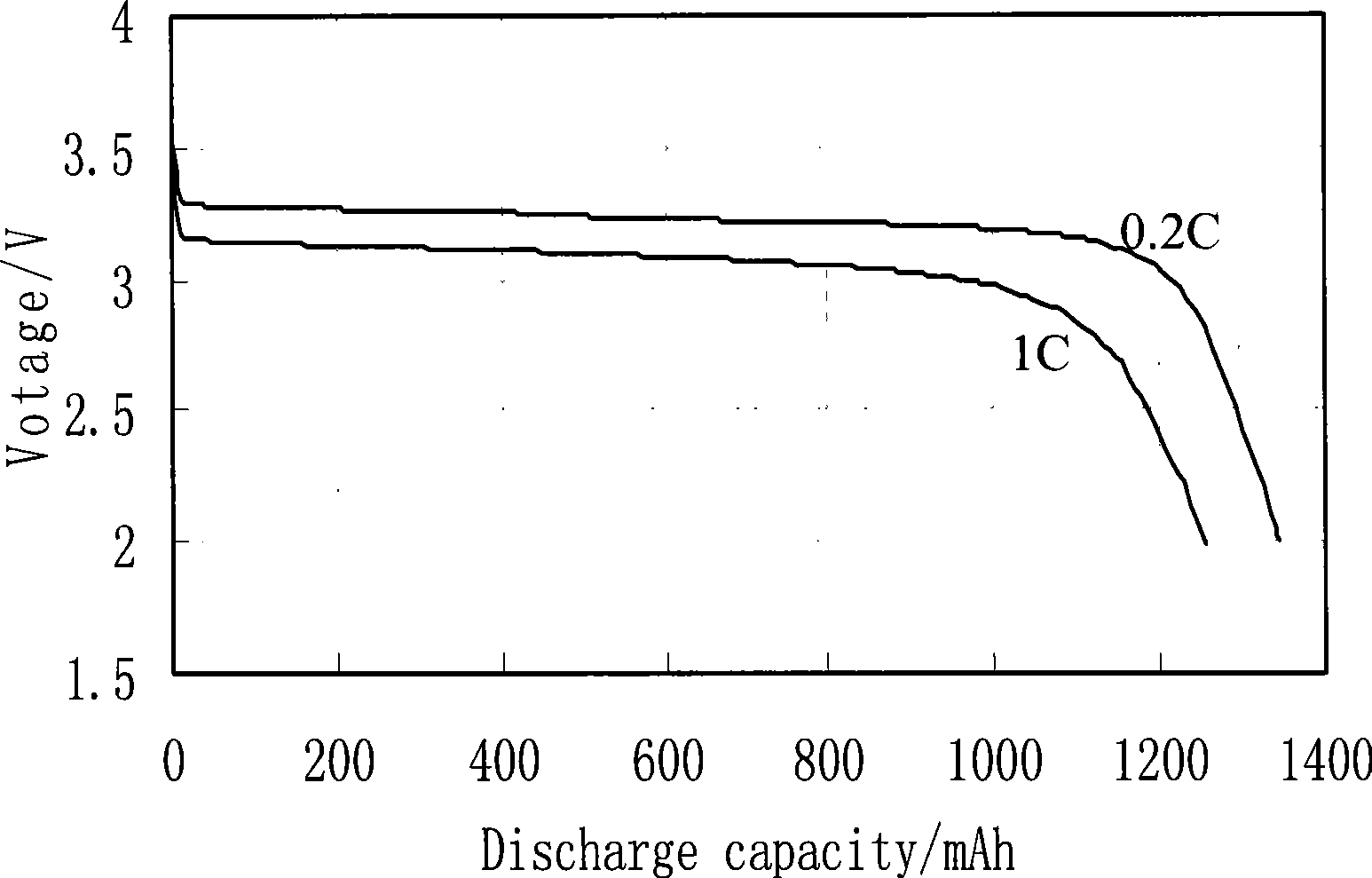

[0028] Put the lithium iron phosphate cathode material waste produced in the production of the 053448A battery of our company in a drying oven, and dry it at 120°C for 10 hours to remove the moisture and solvent absorbed in the waste. Use a mill to mill the dried waste for 6 hours, and then classify the ball milled powder. According to the production process requirements of our company's 053448A battery, the collected particle size is not greater than 20 μm, D 50 The ball milling powder controlled at 3 μm ~ 10 μm (the rest of the ball milling powder can be ball milled and classified again) can obtain the regenerated positive electrode material, and its XRD pattern is as follows Figure 4 Shown, the XRD figure ( figure 1 ) comparison, the positions of the characteristic peaks are basically the same, just because the regenerated positive electrode material obtained by the method of the present invention contains a certain amount of conductive agent and binder, the background of ...

Embodiment 2

[0030] Put the lithium iron phosphate cathode material waste produced in the production of the 053448A battery of our company in a drying oven, and dry it at a temperature of 80°C for 12 hours to remove the moisture and solvent absorbed in the waste. Use a mill to mill the dried waste for 1 hour, and then classify the ball milled powder. According to the production process requirements of our company's 053448A battery, the collected particle size is not greater than 20 μm, D 50 The ball milling powder controlled at 3 μm to 10 μm (the rest of the ball milling powder can be re-classified by ball milling), and the collected ball milling powder was heat-treated for 15 hours under the conditions of an inert atmosphere of argon and a temperature of 400°C. The heat-treated product is crushed and pulverized by a crusher and a pulverizer, and the collected particle size is not greater than 20 μm, D 50 Ball milling powder controlled at 3 μm ~ 10 μm (the rest of the ball milling powder c...

Embodiment 3

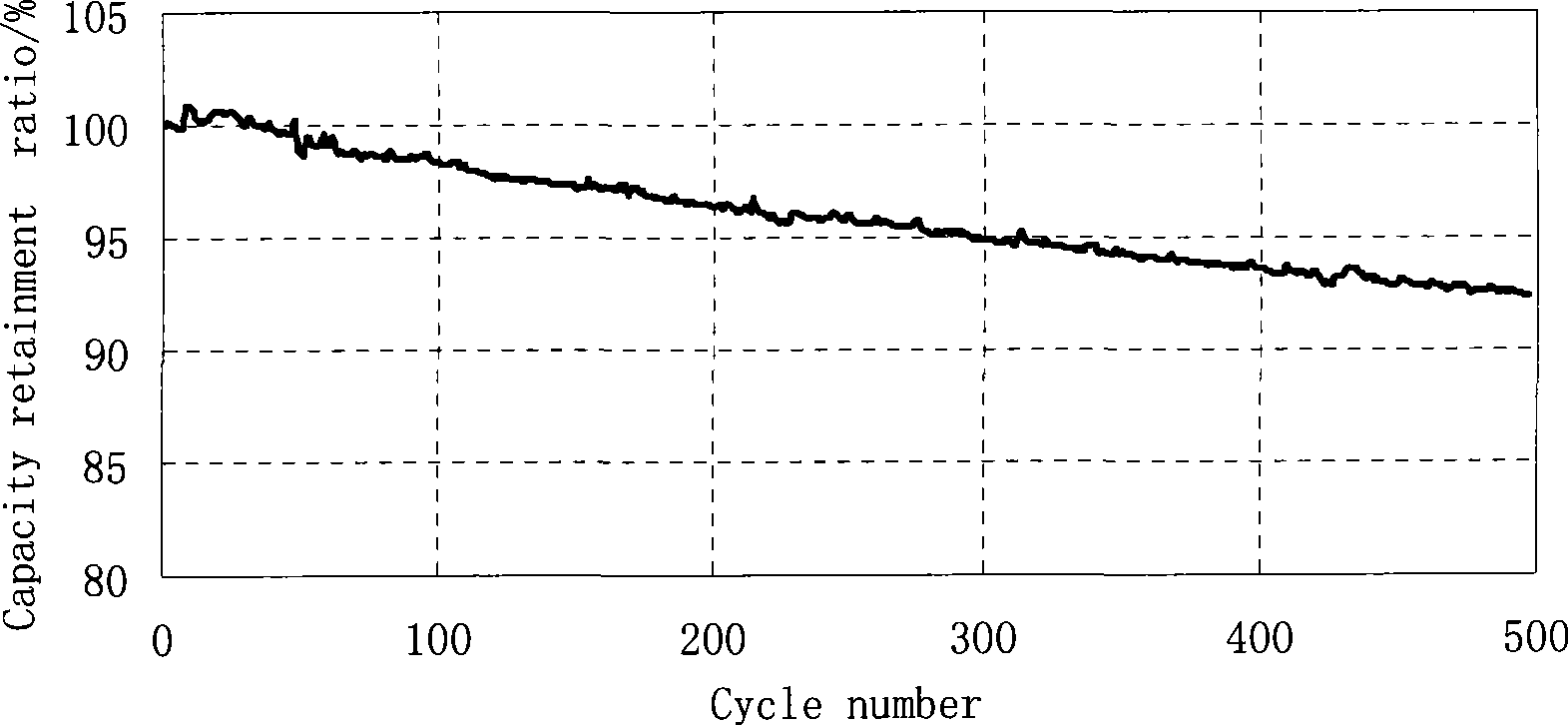

[0032] The difference from Example 2 lies in: the drying temperature is 200°C, and the drying time is 0.5h; the dried waste is ball milled for 10h; the heat treatment temperature is 700°C, and the heat treatment time is 1h. The XRD pattern of lithium iron phosphate regenerated cathode material obtained in this example is as follows Figure 10 shown. Using the regenerated lithium iron phosphate positive electrode material obtained in this example as the positive electrode material, the finished battery is produced according to the proportion and process in Example 1. The 1C cycle performance of the battery is shown in the figure Figure 11 shown. Compared figure 1 and Figure 10, according to the peak intensity (ordinate), it can be seen that the residual carbon and binder content in the regenerated lithium iron phosphate positive electrode material obtained in this example is the same as that in the regenerated lithium iron phosphate positive electrode material obtained in ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com