Process for liquefying high methane gas

A methane gas and methane-enriched technology, applied in liquefaction, refrigeration and liquefaction, gas fuel, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

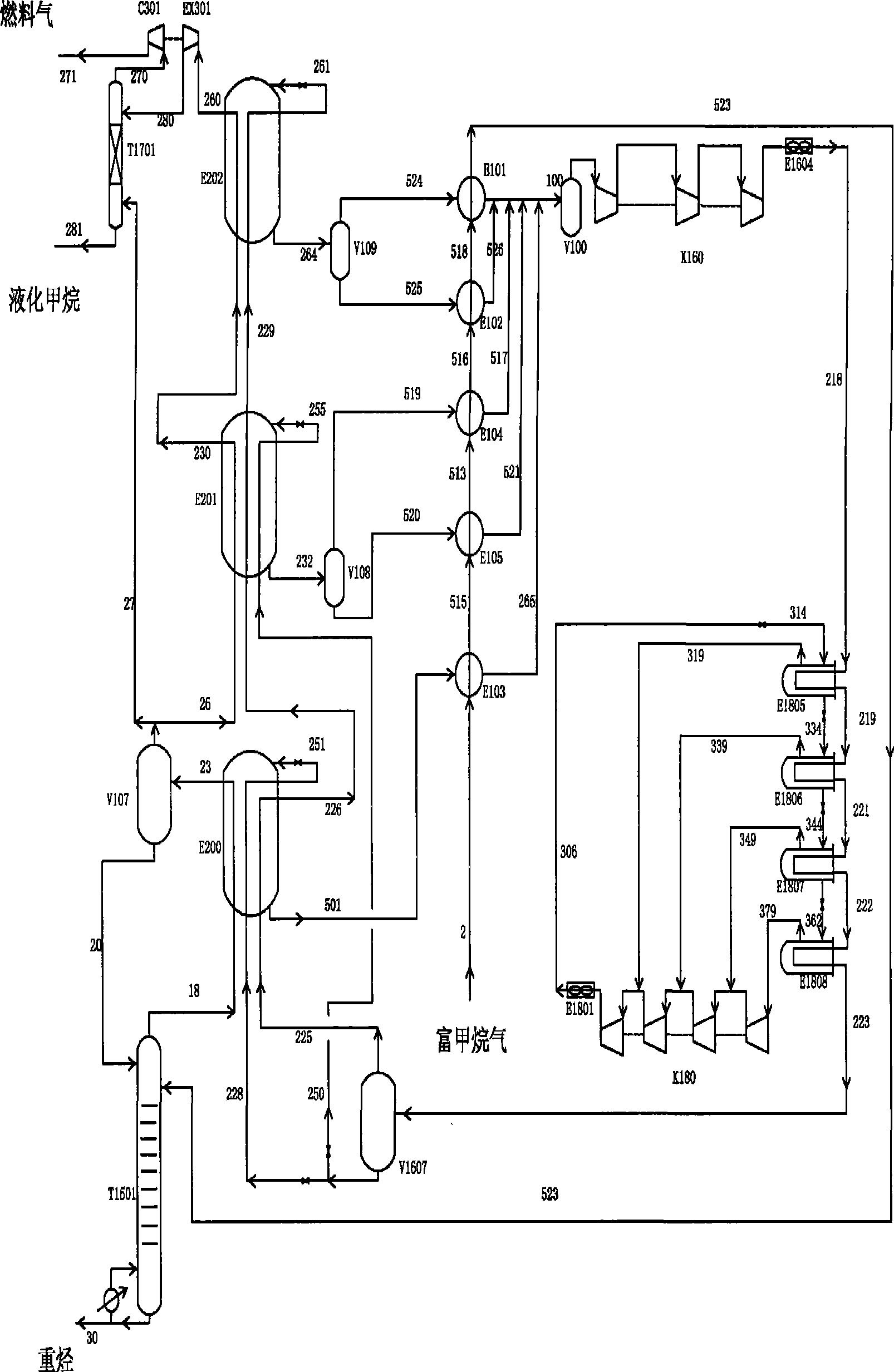

[0050] Example: In order to clarify an embodiment of the present invention, by calculating the heat and material balance of the process from methane-enriched gas to liquefied methane, the optimized implementation of the present invention is simulated to produce 4 million tons of LNG production line per year. see figure 1 .

[0051] The qualified methane-enriched feed gas after pretreatment is 30800kmol / h. At a pressure of 5.9MPa and a temperature of 50°C, it passes through the precoolers E103, E105, E104, E102, and E101 in sequence from pipeline 2, and the methane-enriched gas is precooled to -33°C .

[0052] The raw material gas stream containing condensate enters the demethanizer T1501 through the pipeline 523, and most of the heavy hydrocarbon components are separated in the demethanizer, and the methane-enriched gas at the top of the tower enters through the pipeline 18 at a pressure of 5.3MPa and a temperature of -35°C. The first main heat exchanger E200, after being co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com