Carboxylic fluorescent encoding microsphere and synthetic method thereof

A technology of fluorescent encoding and synthesis method, which is applied in the field of carboxylated fluorescent encoding microspheres and their synthesis, and can solve the problems of reducing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

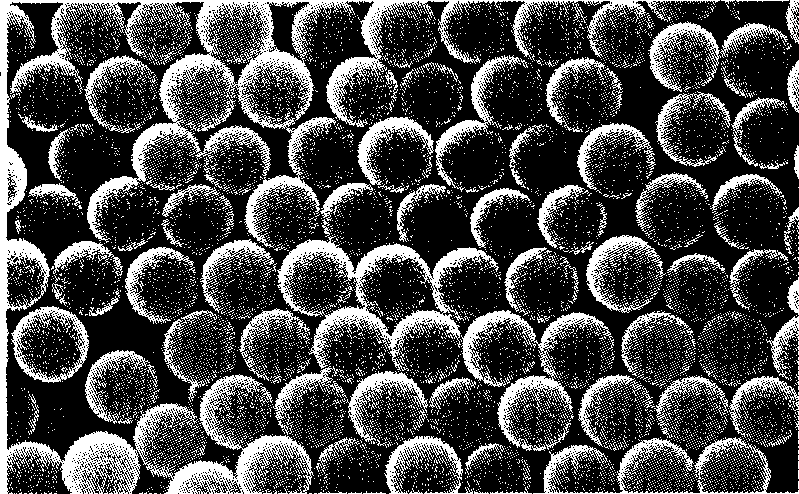

[0025] Embodiment 1: Synthesis of polystyrene seed microspheres with uniform particle size

[0026]Weigh 0.375g of PVP and 0.25g of AIBN, put the weighed PVP into a 100mL three-neck bottle, add 47.5mL of ethanol to dissolve, add a stirring bar, fix, and stir; add the weighed AIBN to a Add 15mL of St and 0.21mL of MAA to the Erlenmeyer flask, oscillate to dissolve, transfer the solution to a cylindrical dropping funnel, then add it dropwise to a three-necked flask, and install a thermometer; 2 After 10 minutes, the reaction was carried out in an oil bath at 70° C., the stirring speed was 250 rpm, and the reaction was stopped after 24 hours. After cooling, the product was transferred to a 50 mL centrifuge tube and centrifuged at 4000 rpm for 5 min, and then washed three times with ethanol and water successively. The obtained microspheres were dried in a vacuum oven at 70 °C for 24 h. The particle size of the obtained microspheres was 5.7 μm, the dispersion coefficient of the p...

Embodiment 2

[0027] Example 2: Preparation of carboxylated fluorescent microspheres

[0028] Weigh 1 g of 4.73 μm polystyrene seed microspheres, 25 mg of sodium dodecyl sulfate (SDS), potassium persulfate (K 2 S 2 o 8 ) 250mg, fluorescein 5mg, add to 100mL three-neck bottle, add 40mL distilled water, ultrasonic for 5 minutes until the solid is completely dispersed. Take another 15mL centrifuge tube, add 4mL methanol, 980μL undecylenic acid, 10μL divinylbenzene, mix well, pipette 250μL solution into a three-necked bottle, pass N 2 5 to 20 minutes. Stir mechanically (250rpm), place in a 70°C oil bath for 7.5h, stop taking out. The obtained microspheres were centrifuged at 6000 rpm for 4 minutes, washed three times with ethanol, and finally washed three times with deionized water, added with deionized water and stored at 4°C. Compared with the particle size of the seed, the particle size of the obtained microspheres basically does not change, and the uniformity is good, and the fluoresce...

Embodiment 3

[0029] Example 3: Detection of the ability of carboxyl groups on the surface of microspheres to fix biomacromolecules

[0030] Accurately pipette 80 μL of activation buffer solution (10mM sodium acetate, pH5.0) into a 1.5mL centrifuge tube, add 5.0×10 6 Microspheres. After mixing, 0.5 mg and 3.3 mg of freshly prepared NHS and EDC solutions were added, the mixture was incubated at room temperature for 20 min, and centrifuged (10000 rpm × 1 min) to remove unreacted NHS and EDC. Add 250 μL of activation buffer solution to wash once and centrifuge to obtain microspheres; add 500 μL of activation buffer solution, mix well, add 30 μg of hepatitis E antibody (HbeAb), mix well and place it on a horizontal shaker at room temperature for 3.5 hours; then add 500 μL Mix the washing buffer solution evenly, remove the supernatant after centrifugation (10000rpm×1min), and finally add 500 μL preservation buffer solution for preservation.

[0031] Pipette 50 μL of 10 μg / mL phycoerythrin-labe...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com