Synthesizing olivine gunning material and production method thereof

A technology for synthesizing olivine and gunning material, which is applied in the field of refractory materials, can solve problems such as limited development and instability of olivine materials, and achieve the effects of low raw material cost, good environmental protection and ecological benefits, and simple and reliable production process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

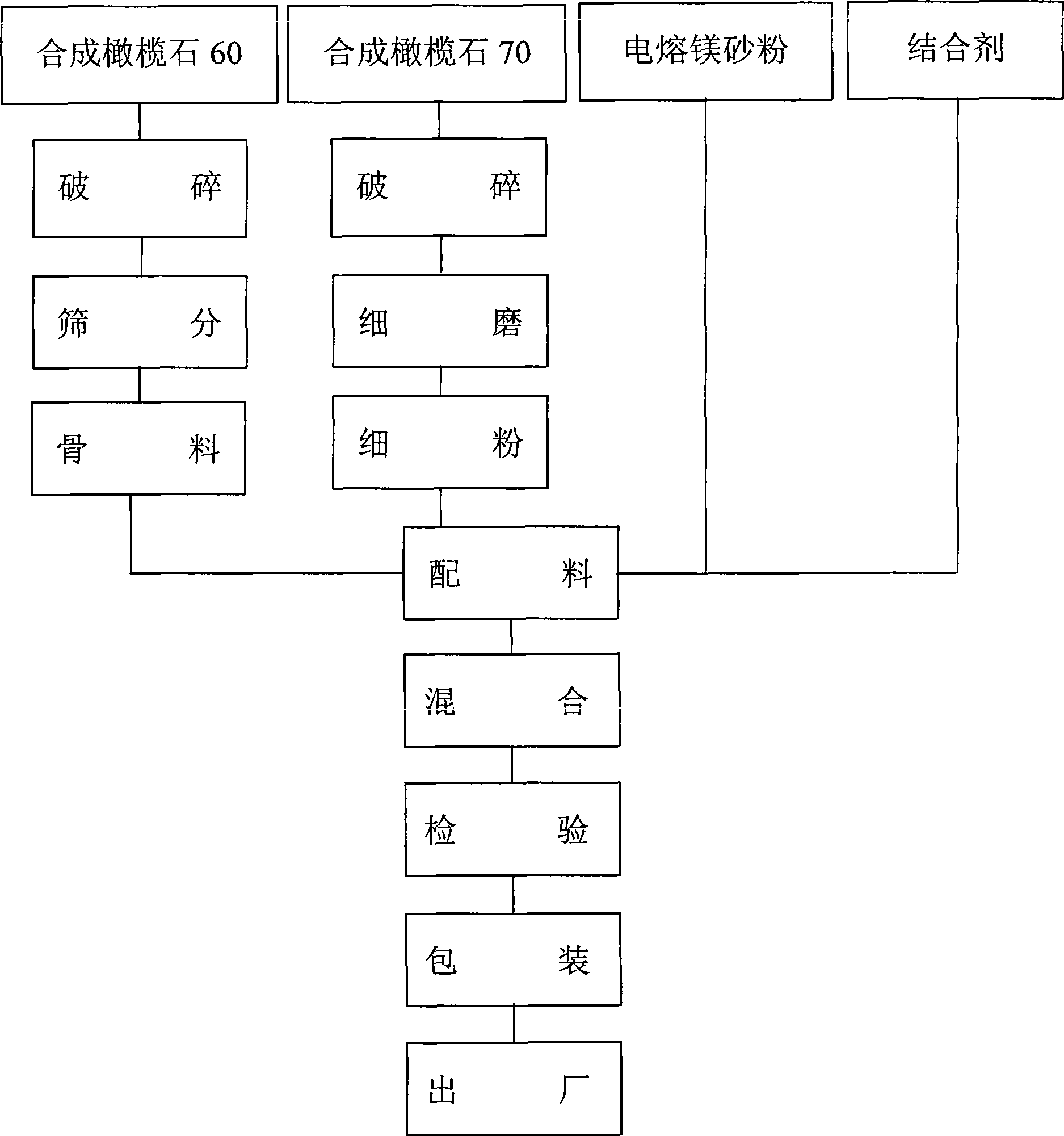

Method used

Image

Examples

Embodiment

[0026] Using the raw materials shown in Table 1 and the ratio given in Table 2, the chemical composition of the synthetic olivine gunning material after mixing is shown in Table 3.

[0027] Table 1 The chemical composition of the raw materials used in the implementation example

[0028] raw material name Ignition loss (%) SiO 2 (%) Fe 2 o 3 (%) al 2 o 3 (%) CaO(%) MgO(%) Synthetic Peridot 60 0.45 27.66 4.56 2.05 1.88 63.40 Synthetic Peridot 70 0.33 25.39 4.40 1.47 1.49 66.92

[0029] Fused magnesia powder 0.42 2.45 0.96 0.26 3.03 92.88

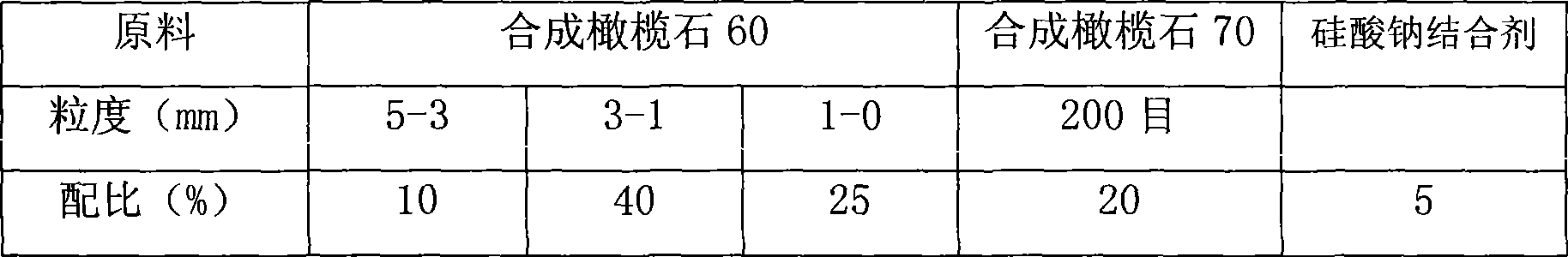

[0030] Table 2 Implementation example with raw materials and proportioning

[0031]

[0032] Table 3 The chemical composition of the synthetic olivine gunning material of the implementation example

[0033] chemical composition Burn out SiO 2 Fe 2 o 3 Al 2 o 3 CaO MgO Synthetic olivine gunning material 1.25 28.06 4.56 2.05 1.79...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com