Motor driver and control circuit board

A technology of motor driver and control circuit board, which is applied in the direction of electronic commutation motor control, single motor speed/torque control, control system, etc. and large issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

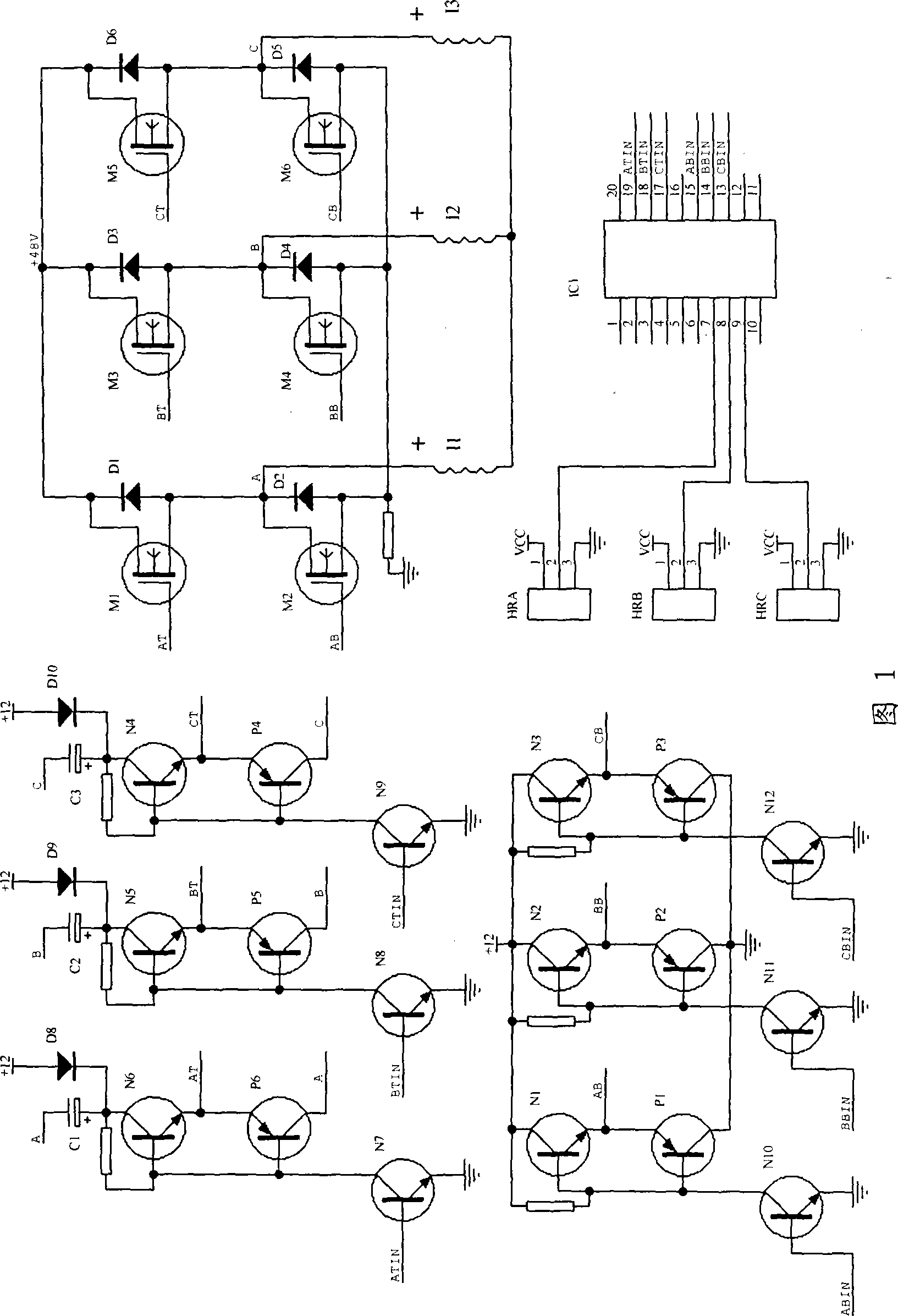

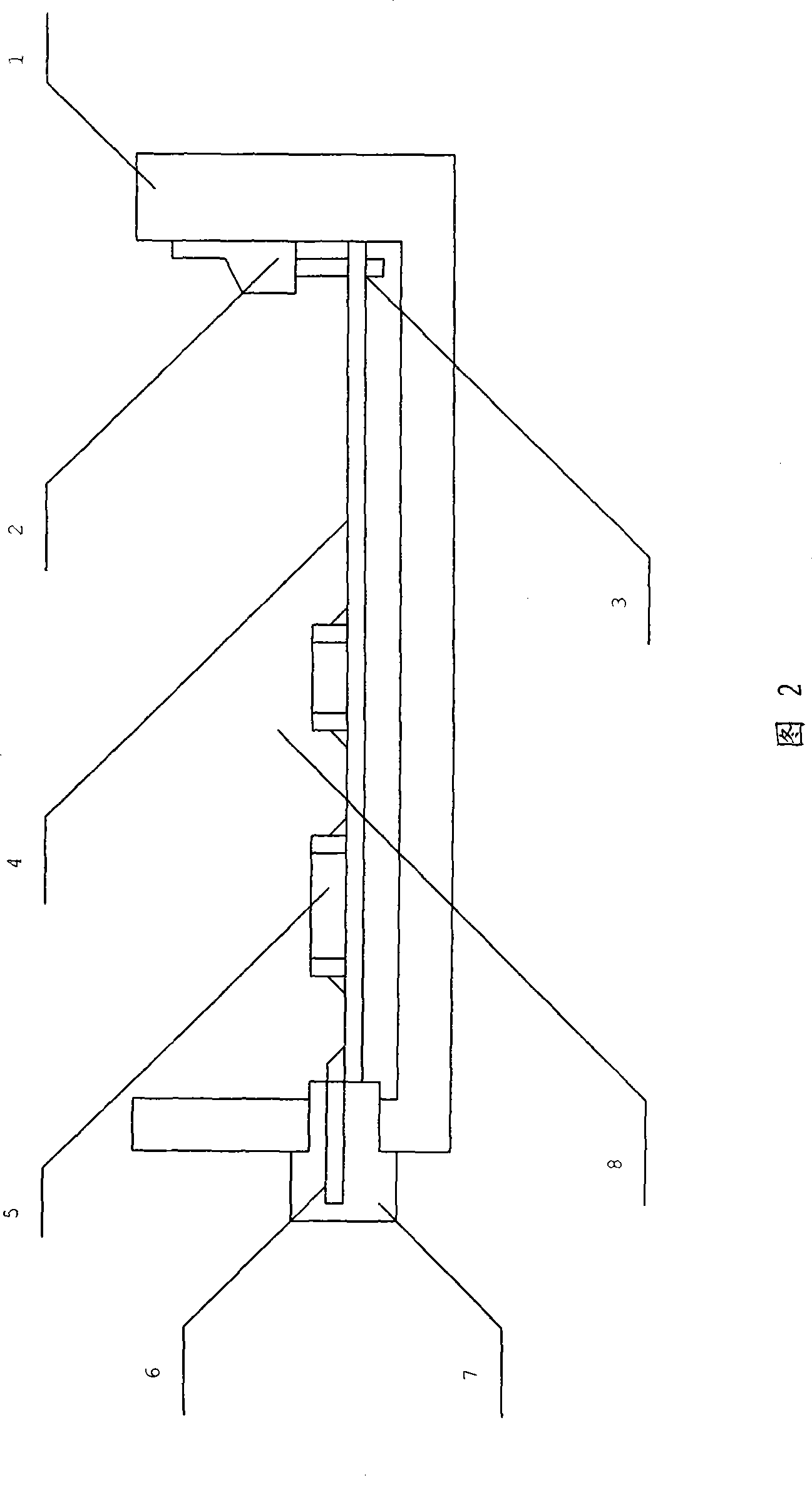

[0010] A motor driver control circuit board, including a microcontroller, a bootstrap circuit and a power supply voltage stabilizing device, is characterized in that the circuit board also has an open excitation circuit and an off excitation circuit, and the microcontroller, bootstrap circuit and power supply The voltage stabilizing device is installed on the same circuit board, and there are pads for installing power devices on the circuit board, and the pads are electrically connected to the open excitation circuit and the close excitation circuit. On the circuit board, there is a device packaged by soldering an SMD; on the circuit board, there is a pad for welding a power supply wire; on the circuit board, there is a pad for a filter capacitor; on the circuit board, there is a soldering motor sensor The first pad of the connecting wire is welded to the second pad of the motor winding connecting wire; the microcontroller is a single-chip microcomputer, and the single-chip mic...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com