Arc welding inversion controlling method based on DSP chip

A technology of inverter control and arc welding, which is applied in the direction of arc welding equipment, computer control, general control system, etc. It can solve the problems of poor anti-interference ability, slow operation speed of single-chip microcomputer, poor programming flexibility, etc., and achieve control flexibility and software The design is flexible and diverse, and the effect of less peripheral circuits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

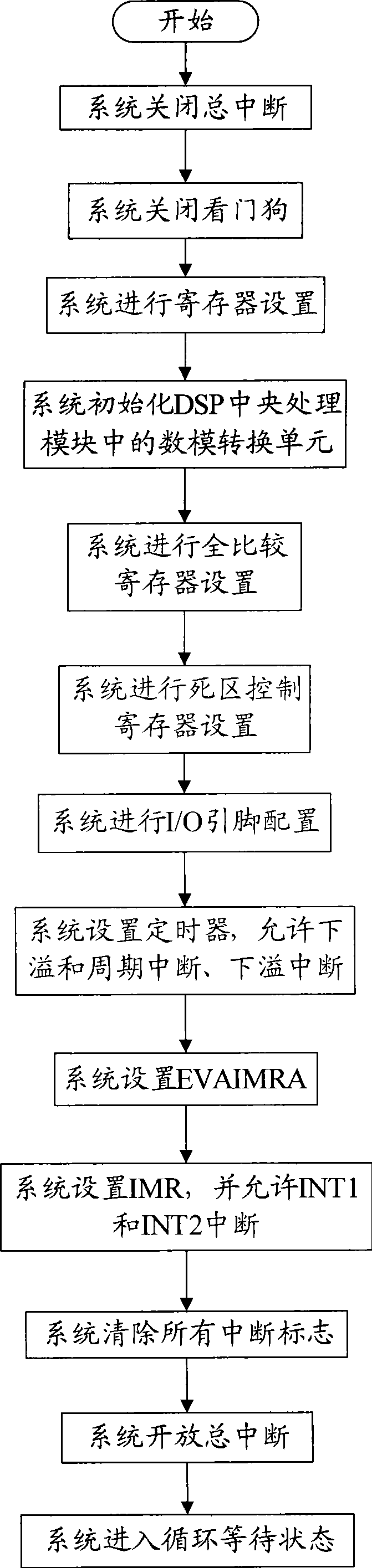

[0030] The DSP chip-based arc welding inverter control method of the present invention will be further described in detail below.

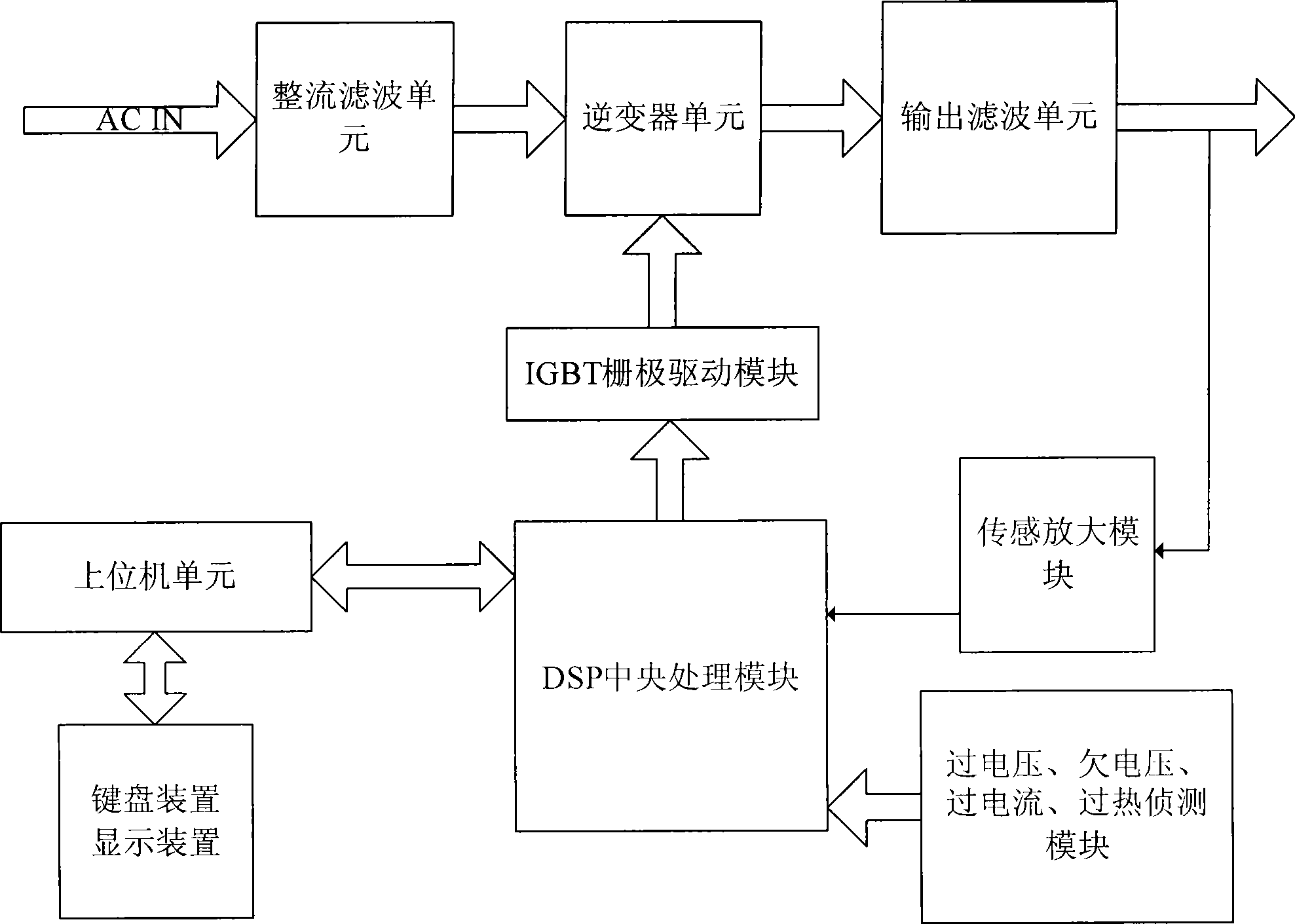

[0031] See figure 1 As shown, the arc welding inverter control system based on the DSP chip, wherein the control system includes a rectification inverter filter function module, an IGBT gate drive module, a DSP central processing module, an input and output module, a sensor amplification module, An overload signal detection module, the DSP central processing module is respectively connected with the input and output modules, the sensor amplification module, and the overload signal detection module, and the DSP central processing module is also driven by the gate of the IGBT The module is connected with the rectification inverter filter function module.

[0032] Wherein, the rectification, inverter and filtering functional module includes a rectification and filtering unit, an inverter functional unit, and an output filtering functional unit. The...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com