Micro-displacement sensor based on ring micro-chamber and cantilever beam of integration plane

A technology of micro-displacement sensor and ring-shaped microcavity, which is applied in the direction of instruments, optical waveguide coupling, TV system components, etc., can solve the problems of large measurement error, high system stability requirements, and the inability to use ordinary light sources, etc., to achieve High sensitivity, reduced operation difficulty, compact and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example

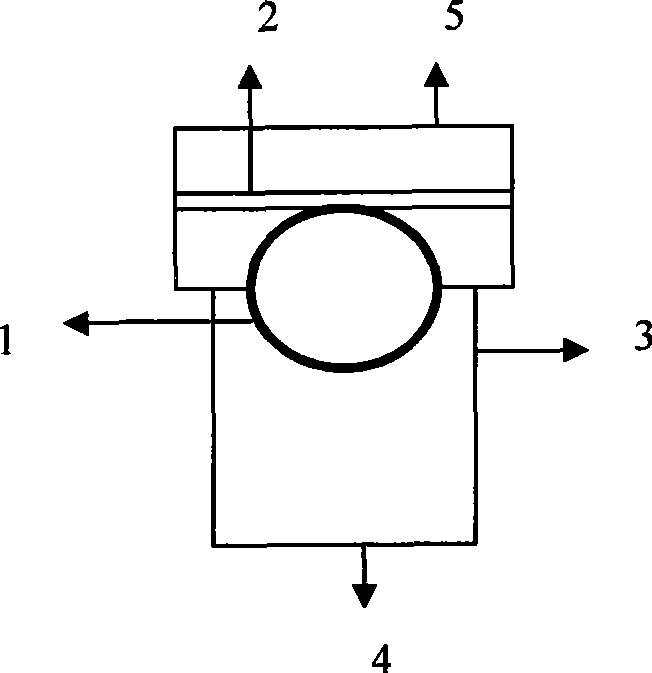

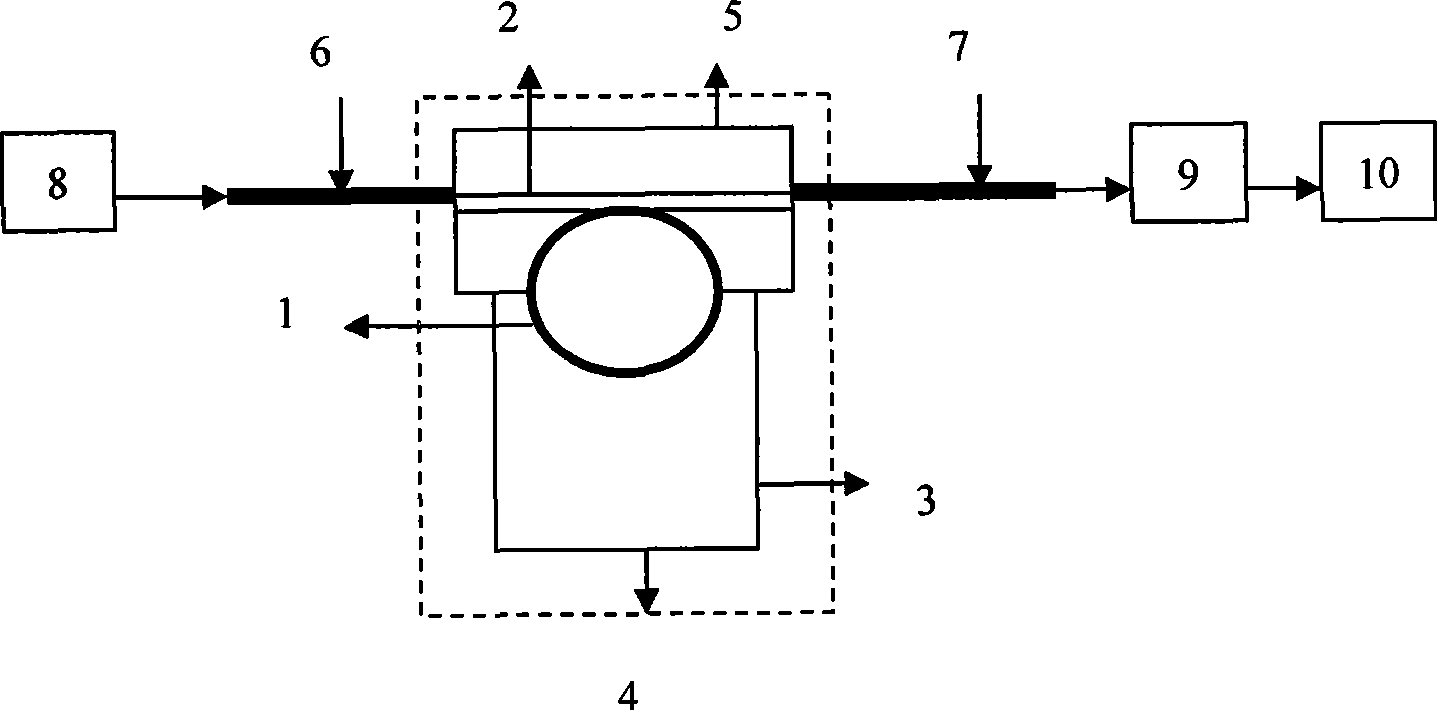

[0029] (1) Planar annular microcavity: use MEMS processing technology to oxidize SiO2 on the surface of Si, and process to form a planar annular microcavity. The material is SiO2, the radius is 20-25um, and the thickness of the ring is 1-2um. In order to obtain a planar annular microcavity with a small half-width value, deep modulation depth, and high quality factor, the inner diameter of the planar annular microcavity is selected as 20um in this example.

[0030] (2) Optical waveguide: the material is SiO2, and the geometric shape is a slender cuboid with a width of 1-2um and a thickness of 0.75-1um.

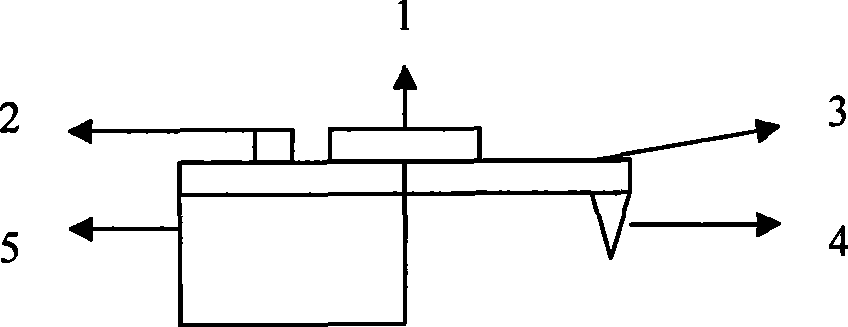

[0031] (3) Cantilever beam: the material is GaAs, the geometric shape is cuboid, wherein the design dimensions of the rectangle can be: length 100-400um, width 20-50um, thickness 0.4-10um.

[0032] Since the stress detection accuracy of the cantilever beam increases with the increase of the length / thickness ratio, in order to obtain high sensitivity, it is advisable to prepare ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com