Graphite-filled vacuum glass tube closed-loop capillary pipe solar thermal-collecting tube

A technology of solar collector tubes and vacuum glass tubes, which is applied in the field of solar collectors, can solve problems such as difficulty in meeting the pressure requirements of building heating systems, affecting solar energy transfer efficiency, and low hot water outlet temperature, so as to eliminate air thermal resistance , small pipe diameter, the effect of improving the pressure bearing capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

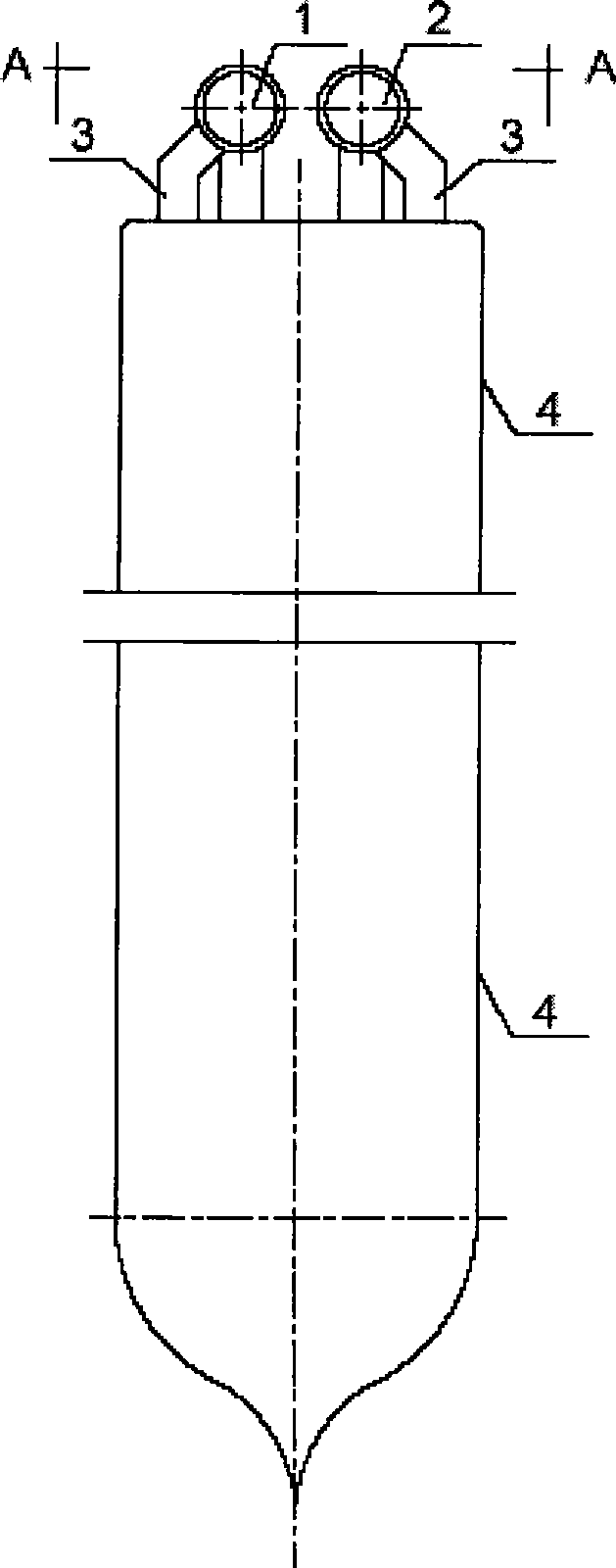

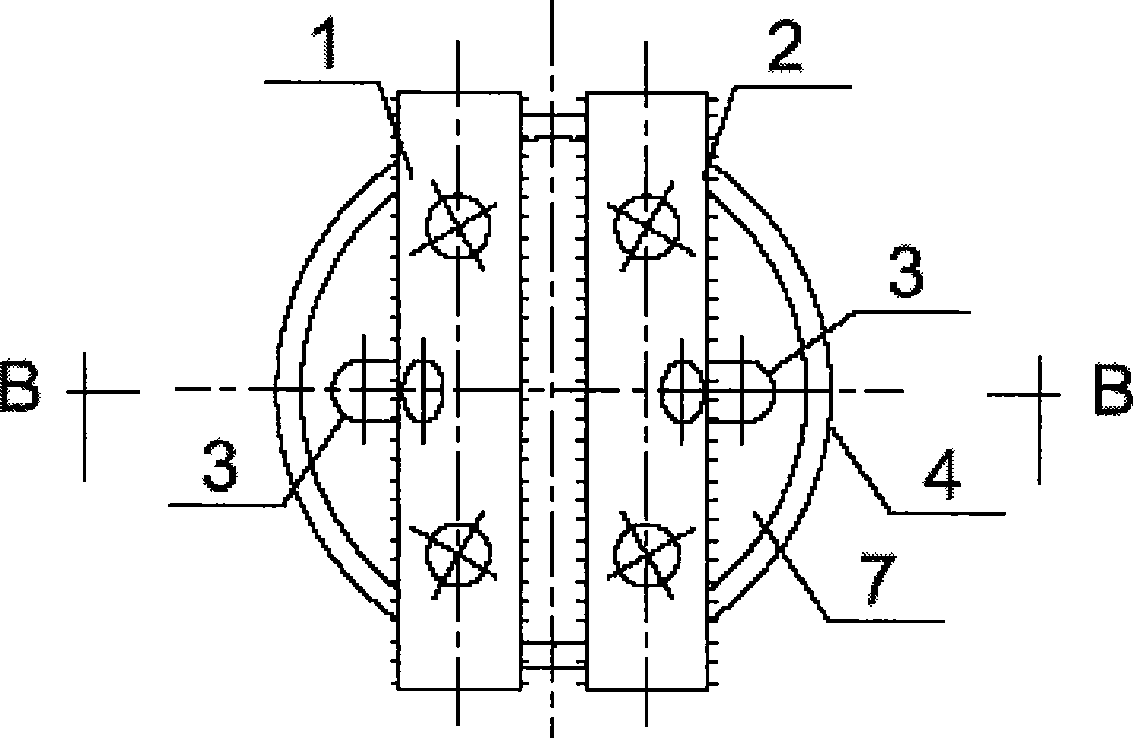

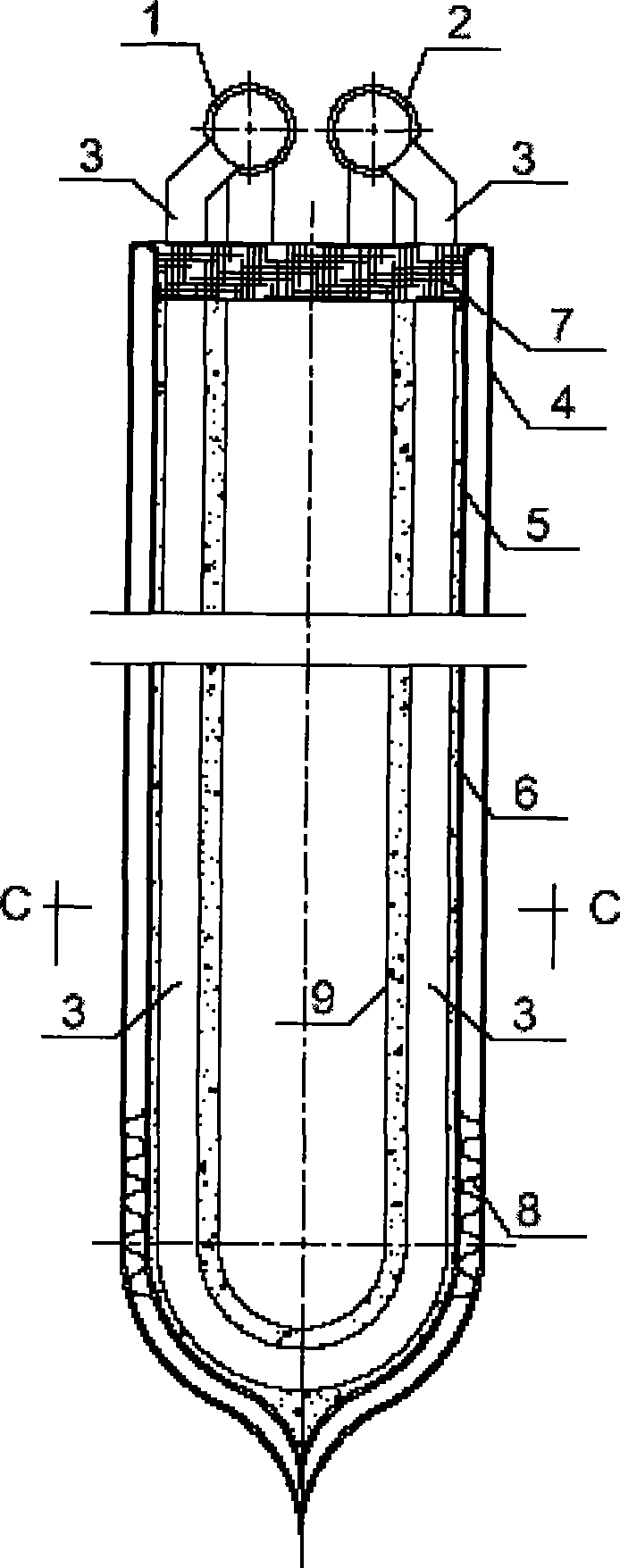

[0017] Specific embodiments of the present invention will be described in detail below in conjunction with technical solutions and accompanying drawings.

[0018] The graphite-filled vacuum glass tube closed-loop capillary solar heat collection tube of the present invention is mainly composed of a first finned header tube 1, a second finned header tube 2, a capillary metal tube 3, an outer glass tube 4, an inner glass tube 5, graphite It is composed of filler 6, heat insulating head 7, elastic support 8 and heat insulating liner pipe 9. The finned header tube and the capillary metal tube are connected by welding; the capillary metal tube 3 is installed in the graphite filler 6 to form a whole and installed in the vacuum glass tube, and the upper opening of the vacuum glass tube is sealed with a thermal insulation head 7 ; After the outer surface of the inner glass tube 5 is sprayed with solar selective absorption paint, it is welded with the outer glass tube 4 and vacuumized, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com