Graphite-filled vacuum glass tube open type capillary pipe solar thermal-collecting tube

A solar collector tube and vacuum glass tube technology, which is applied in the field of solar collectors, can solve the problems of difficulty in meeting the pressure bearing requirements of a building heating system, affecting the efficiency of solar energy transfer, and low temperature of hot water outlet, etc., so as to eliminate air thermal resistance. , Small pipe diameter, the effect of improving the pressure bearing capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The specific embodiments of the present invention will be described in detail below in conjunction with the technical solution and the drawings.

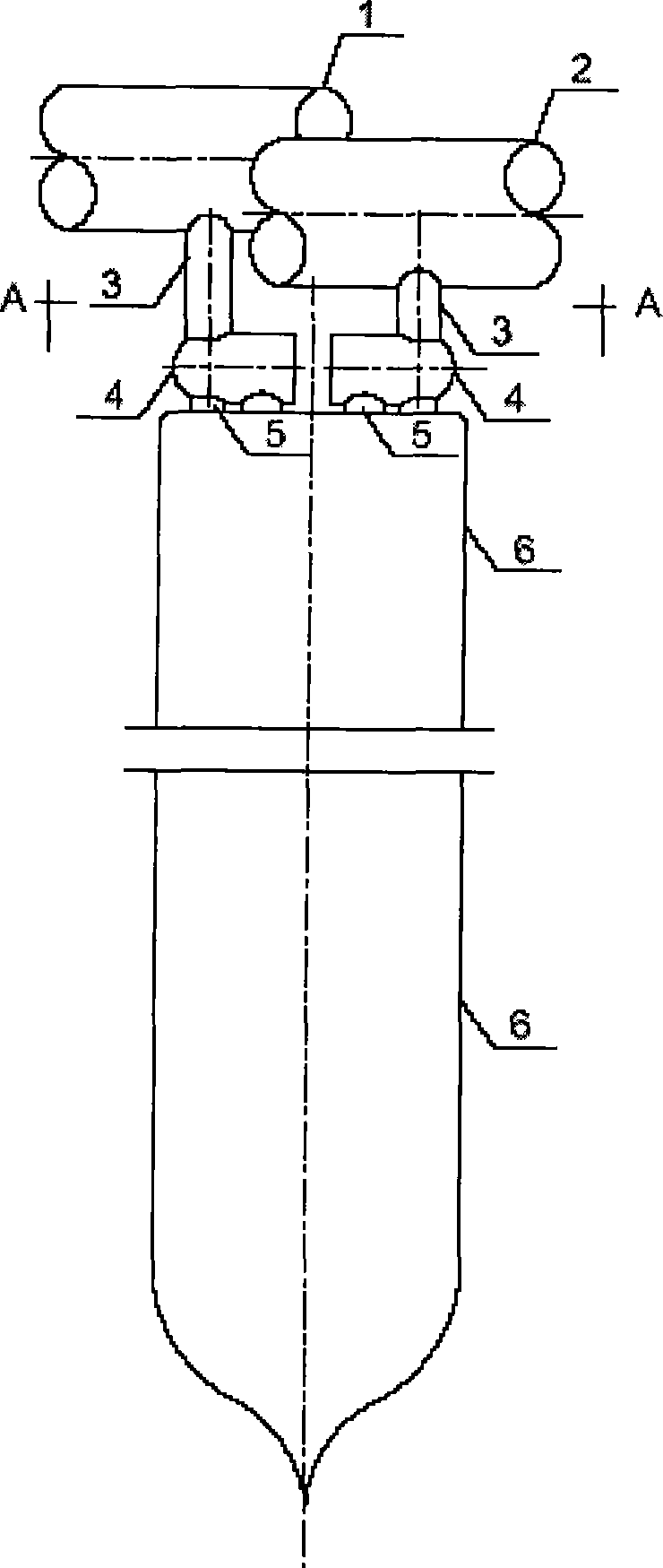

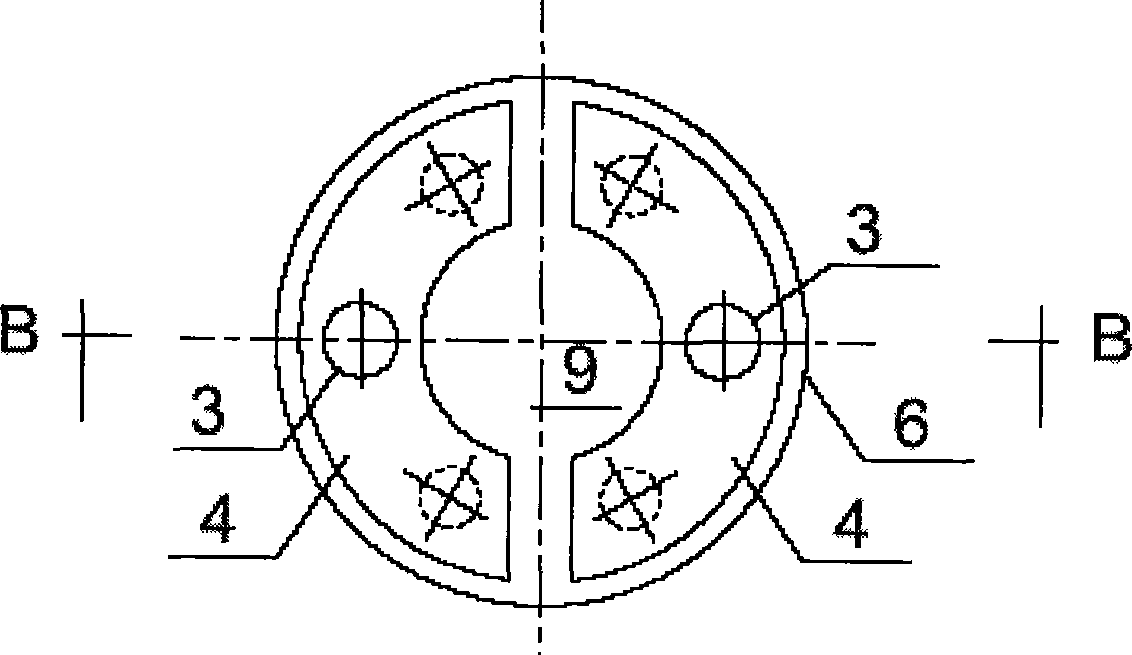

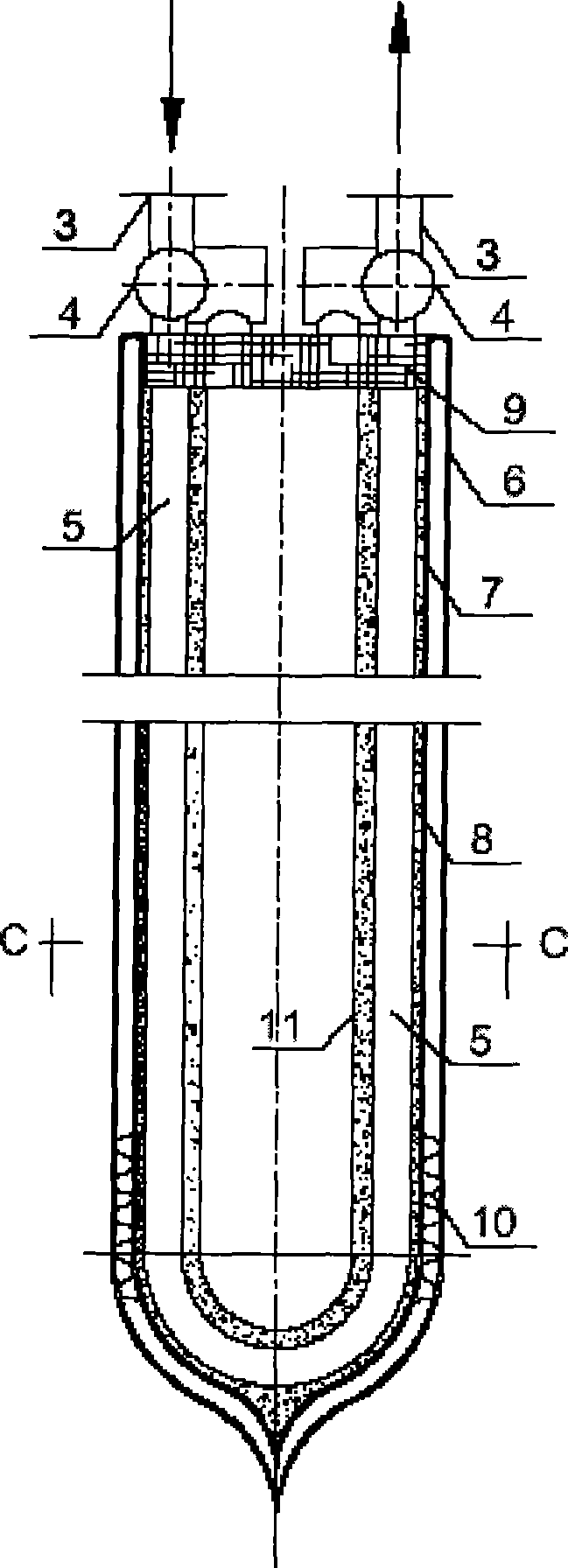

[0018] The graphite-filled vacuum glass tube open capillary solar heat collector tube of the present invention is mainly composed of a first header tube 1, a second header tube 2, a header connection tube 3, a manifold 4, a U-shaped capillary metal tube 5, and an outer glass tube 6. , Inner glass tube 7, graphite packing 8, heat insulation seal head 9 and elastic support 10; the first header tube 1 and the second header tube 2, the header connection 3, the manifold 4 and the U-shaped capillary metal tube 5 The successive connection between them adopts welding connection; the U-shaped capillary metal tube 5 is installed in the graphite packing 8 to form a whole and installed in the vacuum glass tube, and the upper opening of the vacuum glass tube is sealed with an adiabatic sealing head 9; the inner glass After the outer surface o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com