Thermal insulation concrete brick and special synchronous core-building apparatus

A technology of thermal insulation concrete and blocks, which is applied in the direction of building materials, ceramic molding machines, manufacturing tools, etc., can solve the problems of low production efficiency, complicated manufacturing process, large labor input and labor intensity, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] Further illustrate the present invention below in conjunction with accompanying drawing.

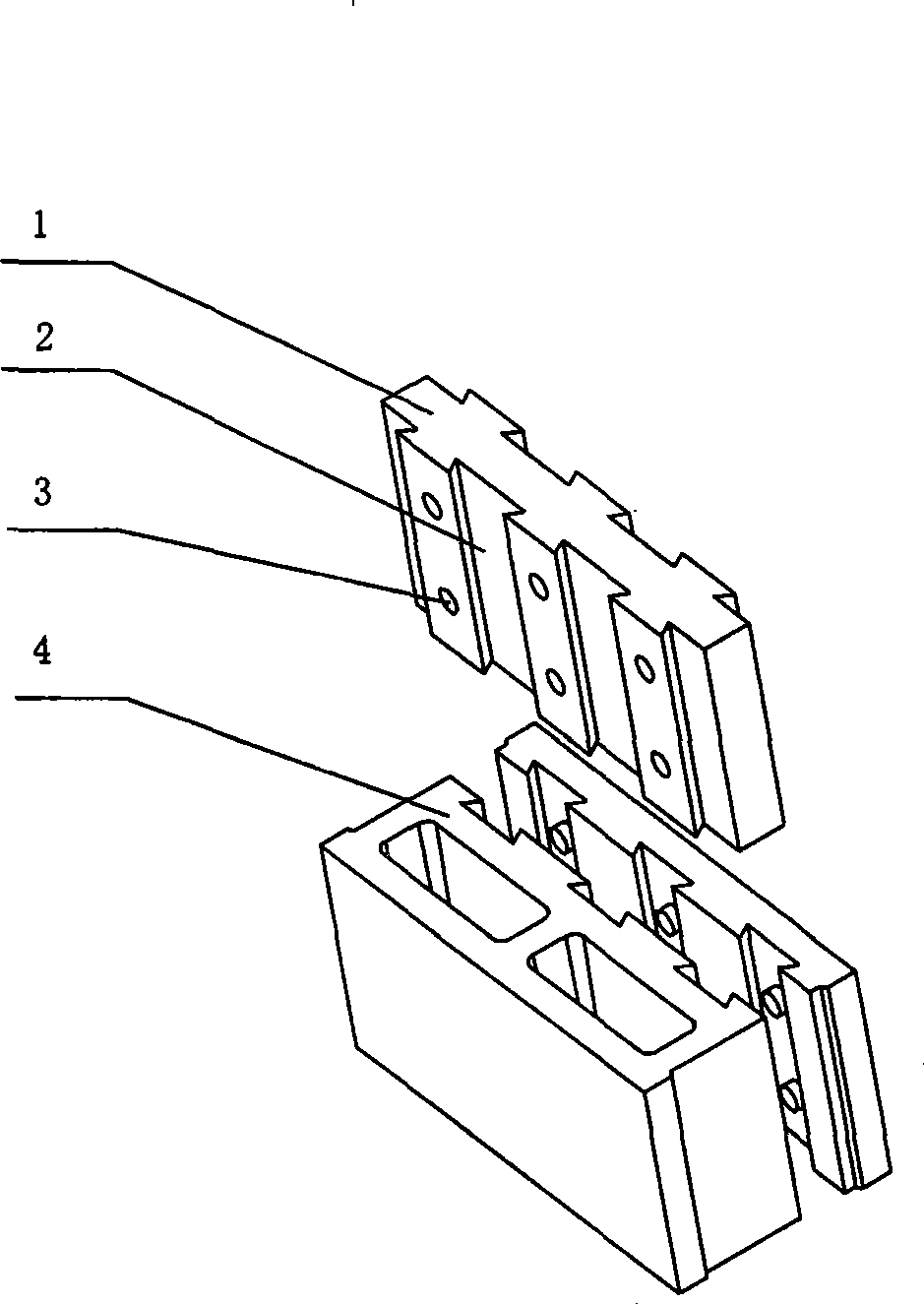

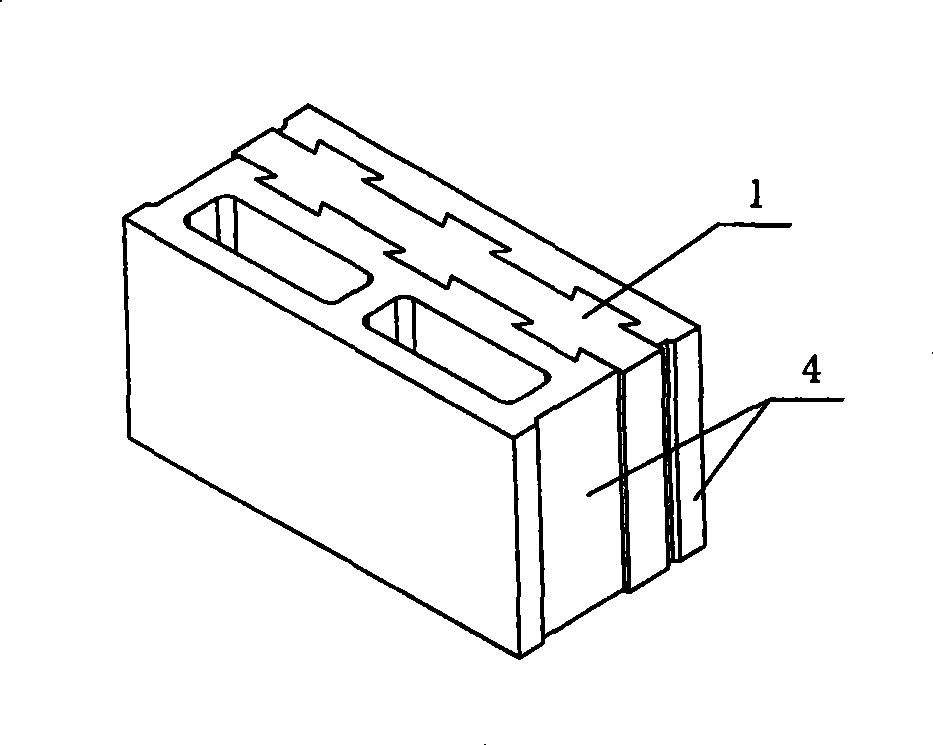

[0026] Such as figure 1 In the present invention, dovetail grooves 2 are respectively provided on both sides of the heat preservation core layer 1, and pits 3 are respectively arranged on both sides of the heat insulation core layer 1 or on the bottom surface of the dovetail groove 2 grooves; When the concrete blocks 4 are molded, they correspond to the surface shape of the insulation core layer 1, and part of the concrete flows into the dovetail groove 2 and the pit 3. After drying, the insulation core layer 1 is fixedly connected with the concrete blocks 4 on both sides. At least one of the dovetail groove 2 and the pit 3 is arranged on both sides. The dovetail groove 2 runs through the height direction of the insulation core layer.

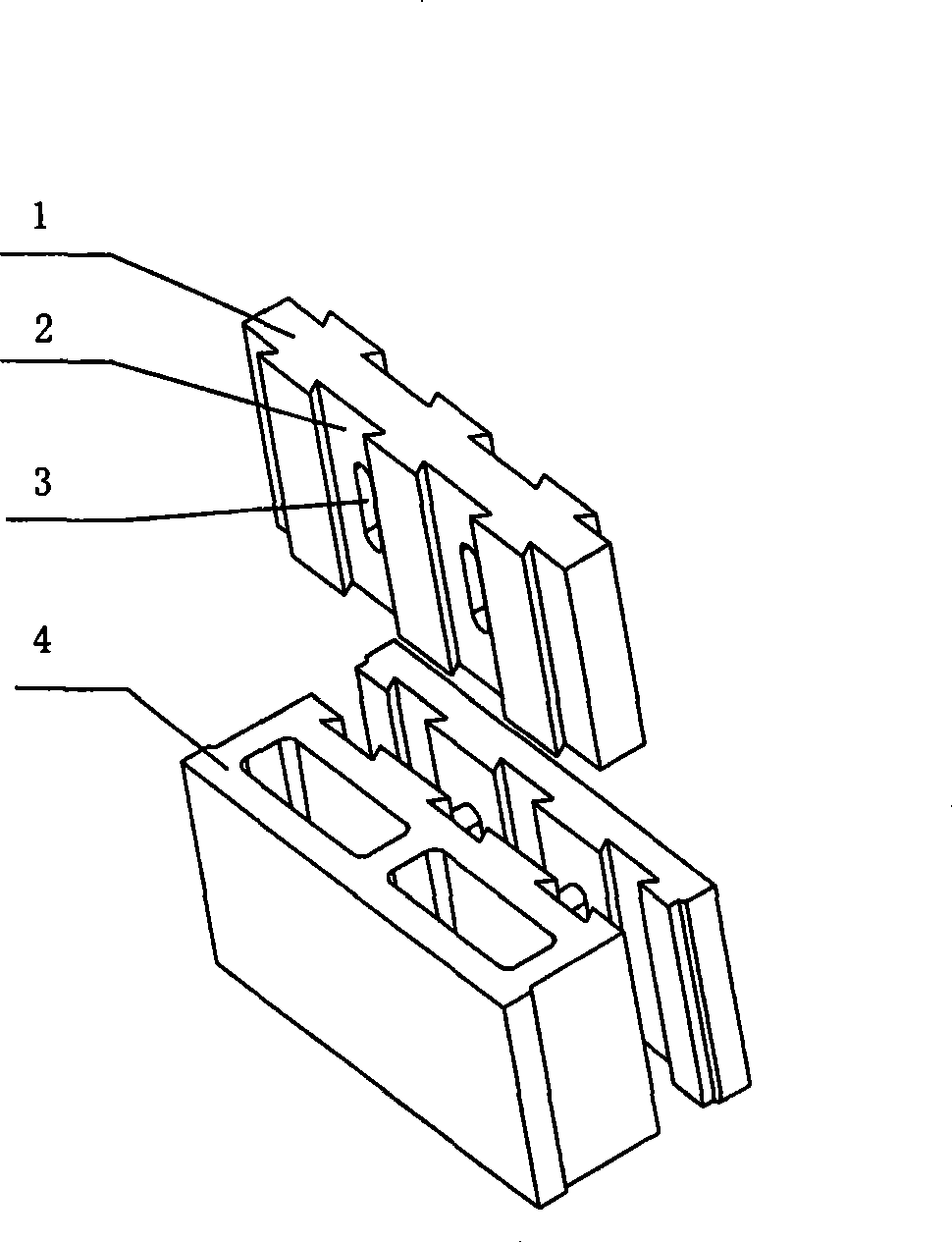

[0027] Such as figure 2 The pit 3 in the present invention can also be a waist-shaped through hole penetrating through the thickness direction...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com