Shawl production chain

A technology of production line and scarf, applied in the field of sewing production line, can solve the problems of low productivity and difficulty in quality assurance, and achieve the effects of productivity improvement, quality assurance, and reduction of human intervention factors

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

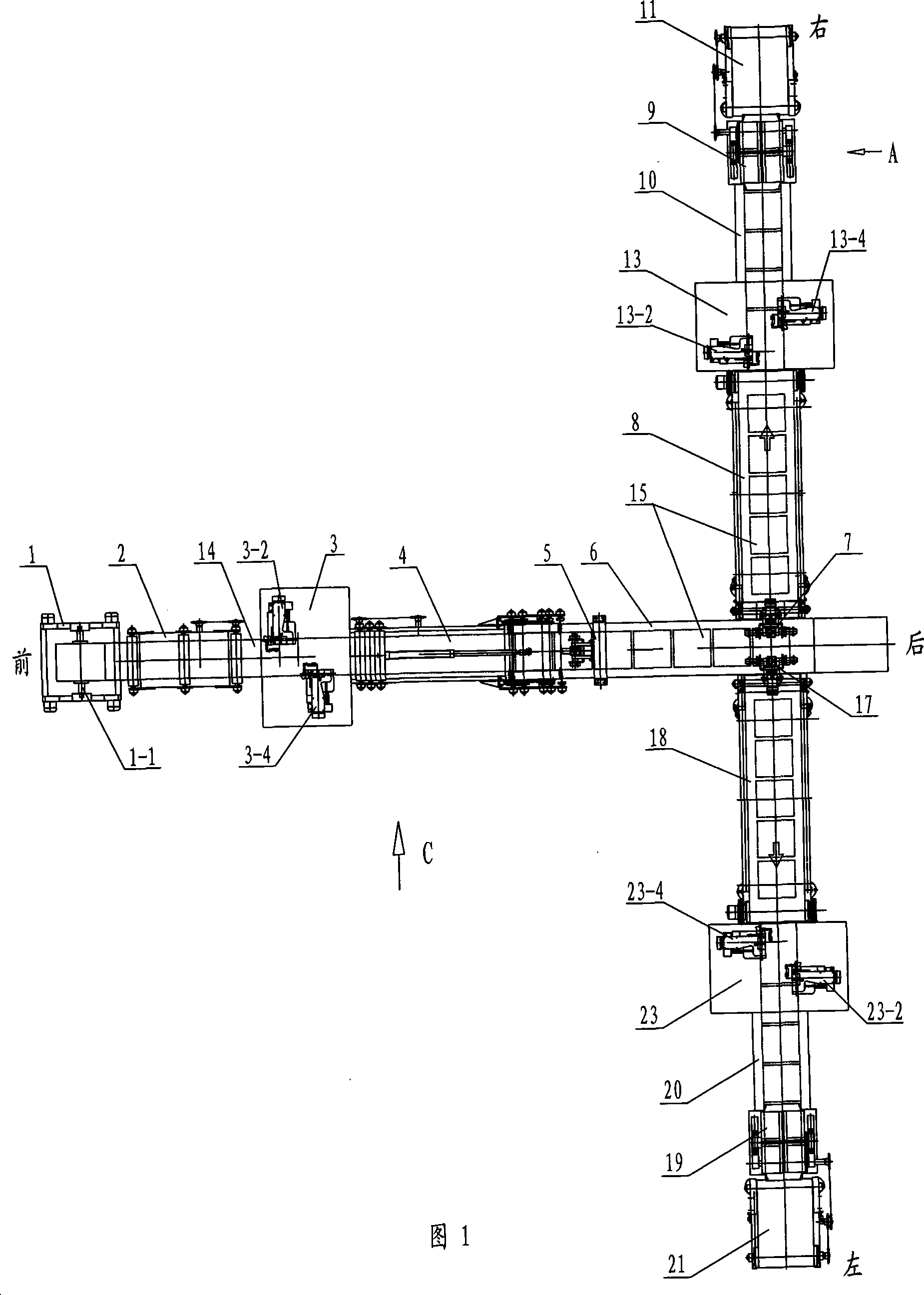

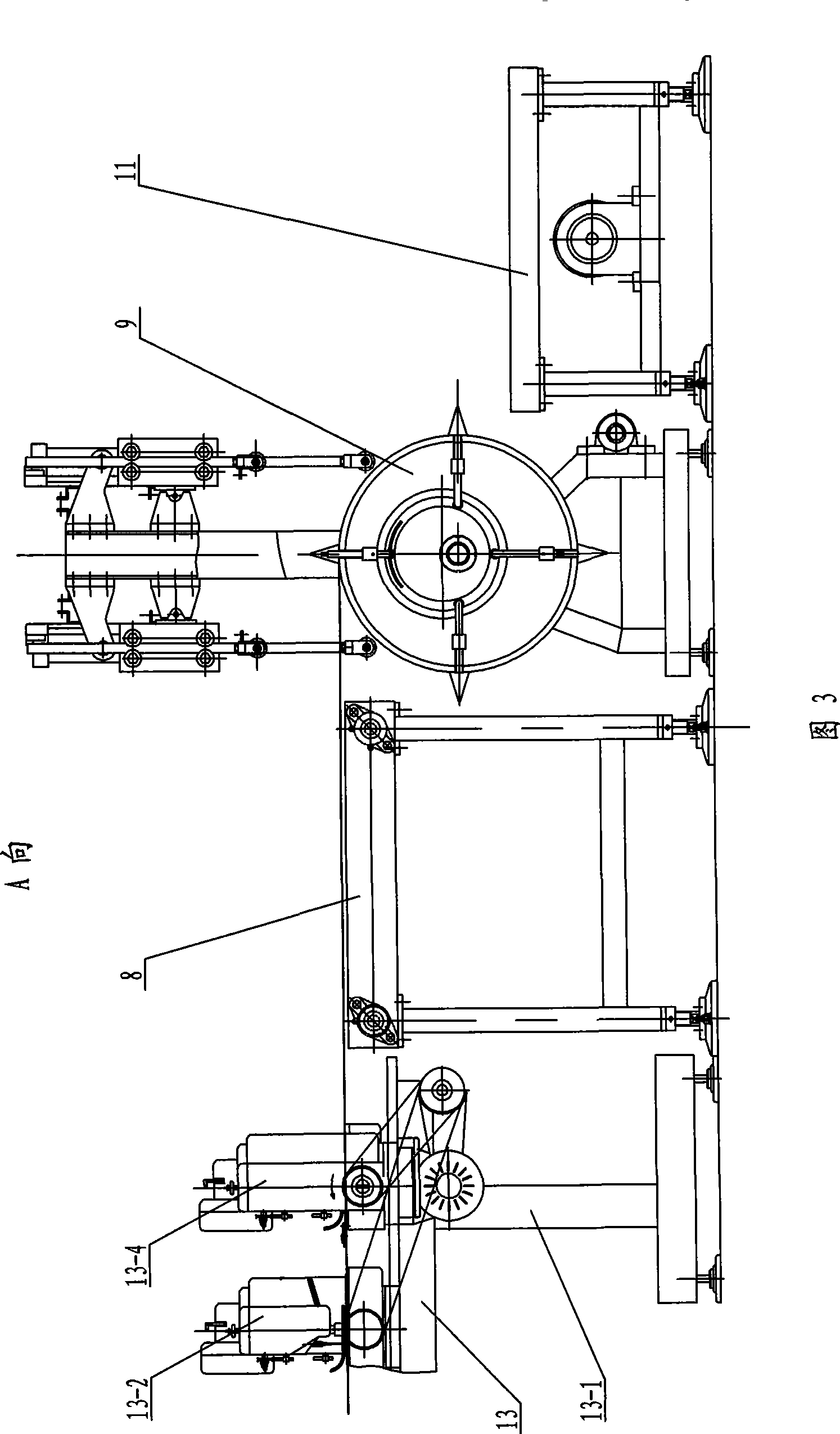

[0007] Specific implementation mode one: in conjunction with Fig. 1~ Figure 4 and Figure 10 Describe this embodiment, this embodiment includes a damping unwinder 1, a synchronous conveyor 2, the first double-head sewing device 3, a reclaiming conveyor 4, a labeling machine 5, a conveyor 6, and a first horizontal reclaimer 7. The first horizontal conveyor 8, the first head cutting machine 9, the first intermediate conveyor 10, the first material receiving machine 11 and the second double-head sewing device 13, the damping unwinding machine 1, the synchronous conveyor 2, The first double-head sewing device 3, the retrieving conveyor 4 and the conveyor 6 are vertically arranged on the ground from front to back, and the first transverse conveyor 8, the second double-head sewing device 13, and the first intermediate conveyor Machine 10, the first head-cutting machine 9 and the first material receiving machine 11 are horizontally arranged on the ground sequentially from the right ...

specific Embodiment approach 2

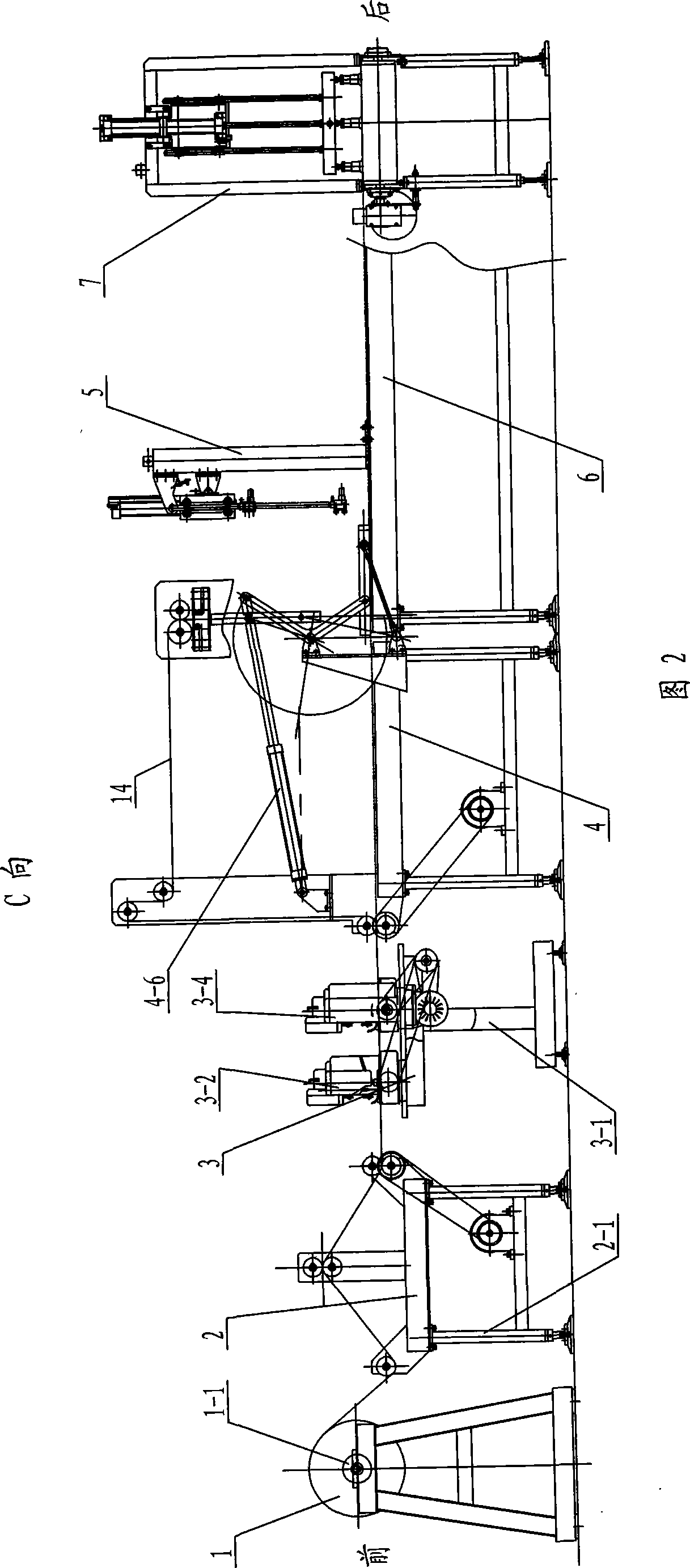

[0008] Specific embodiment two: in conjunction with Fig. 2 and Figure 5 Describe this embodiment, the synchronous conveyor 2 of this embodiment is by synchronous frame 2-1, driving guide roller 2-2, middle guide roller 2-3, passive guide roller 2-4, secondary motor 2-5 and first The belt is composed of 2-6, the middle guide roller 2-3 is arranged in the middle position above the synchronous frame 2-1, and the passive guide roller 2-4 is arranged on the synchronous frame 2-1 and close to one end of the damping unwinder 1, The driving guide roller 2-2 is arranged on the synchronous frame 2-1 and is close to one end of the first double head sewing device 3, and the belt pulley on the driving guide roller 2-2 passes through the belt 2-6 and the auxiliary motor 2-5 output shaft on the pulley connection.

specific Embodiment approach 3

[0009] Specific embodiment three: in conjunction with Fig. 1, Fig. 2 and Figure 6 Describe the present embodiment, the reclaiming conveyor 4 of the present embodiment is made of reclaiming frame 4-1, lower guide roller 4-2, transition guide roller 4-3, upper guide roller 4-4, main motor 4-5, Manipulator reclaimer 4-6, two front supports 4-7, two rear supports 4-8, cutter 4-9 and the second belt 4-10 are formed, and two front supports 4-7 are respectively fixed on the On both sides of the front end of the material frame 4-1, two rear supports 4-8 are respectively fixed on both sides of the rear end of the reclaimer frame 4-1, and the lower guide roller 4-2 is arranged on the two front supports 4-7 And be positioned at the lower end of front bracket 4-7, transition guide roller 4-3 is arranged on two front brackets 4-7 and is positioned at the upper end of front bracket 4-7, and upper guide roller 4-4 is arranged on two rear brackets 4-7. 8 and is positioned at the upper end o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com