Method for regenerating oxidation coenzyme I using intact cell bioconversion

An oxidized coenzyme and coenzyme technology, applied in the direction of microorganism-based methods, biochemical equipment and methods, microorganisms, etc., can solve the problems of large molecular weight and difficulty, and achieve the effect of improving conversion efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

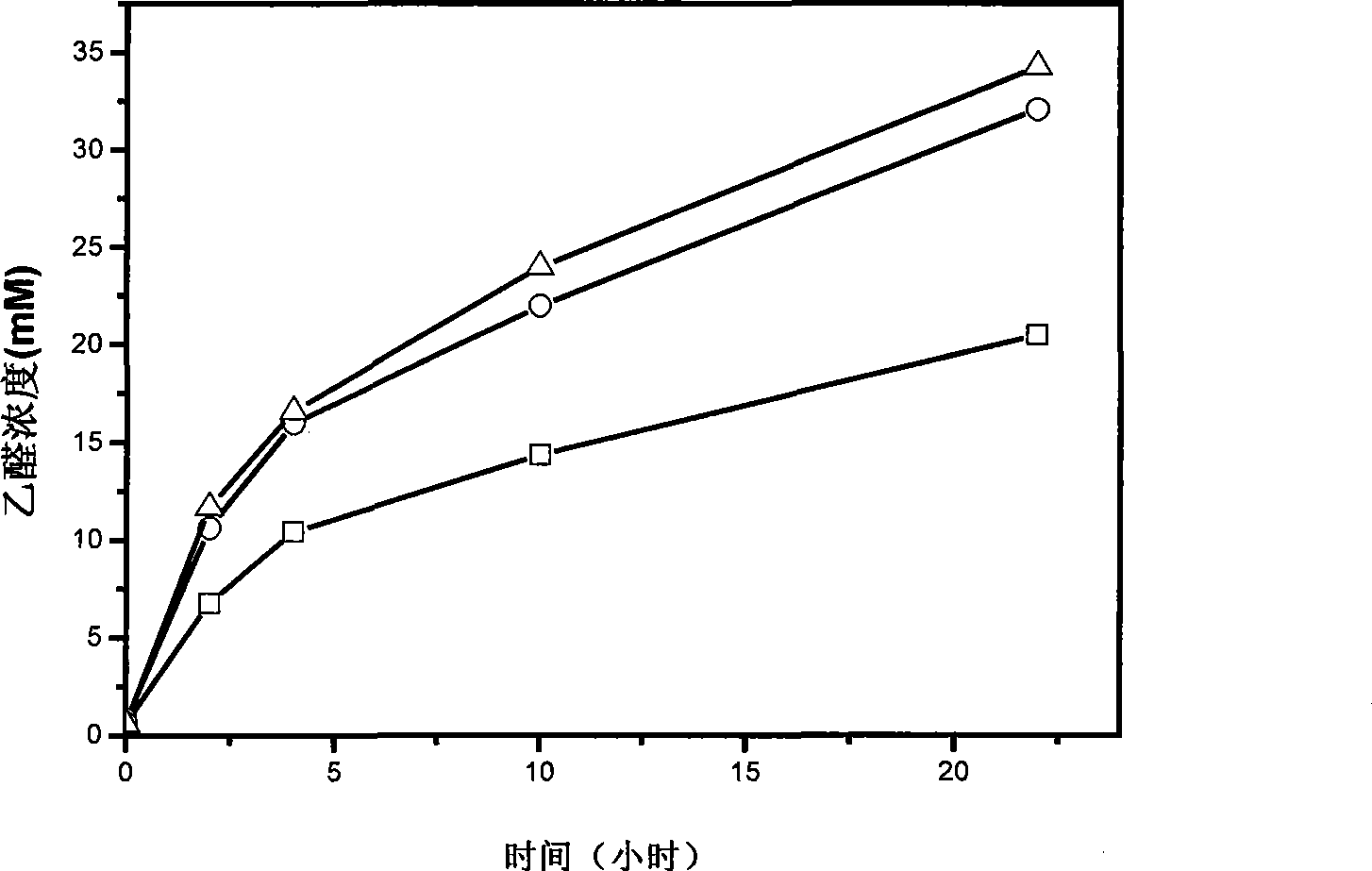

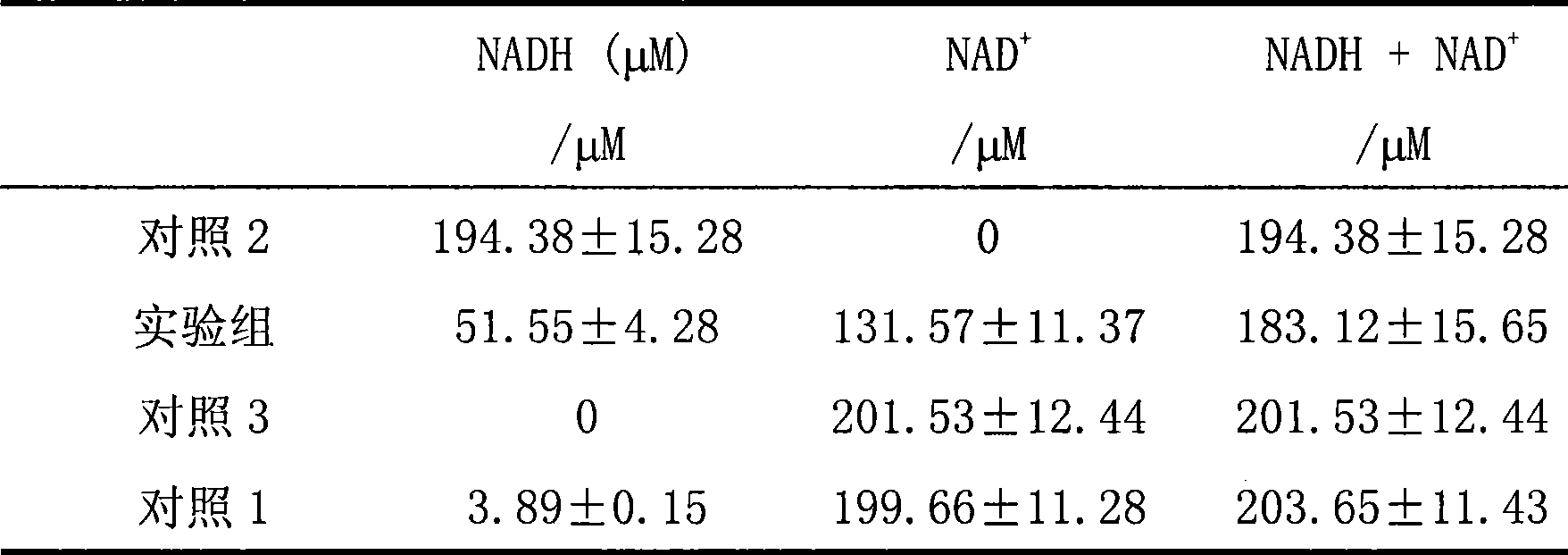

[0012] Example 1. Enterobacter aerogenes converts NADH into NAD +

[0013] 1) Culture Enterobacter aerogenes

[0014] Enterobacter aerogenes (Enterobacteraerogenes) IAM1183 was inserted into the culture medium (glucose 15g / L, peptone 5g / L, K 2 HPO 4 14g / L, KH 2 PO 4 6g / L, (NH 4 ) 2 SO 4 2g / L, MgSO 4 ·7H 2 O 0.2g / L), 37°C, 170rpm air bath shaker culture.

[0015] Take 60ml of Enterobacter aerogenes IAM1183 cultured in an aerobic shake flask for 12 hours, centrifuge at 10,200×g at 4°C for 5 minutes, and collect Enterobacter aerogenes cells.

[0016] 2) NADH is converted to NAD +

[0017] Wash the Enterobacter aerogenes cells in step 1) three times with 50 mM triethanolamine buffer (TEA) at pH 6.80, then resuspend in 50 mM triethanolamine buffer (TEA) at pH 6.80, and adjust the cell concentration to OD 600 to 0.8, NADH was added to make the final concentration of NADH 210 μM, cultured at 37°C and 170 rpm, as the experimental group.

[0018] Wash the Enterobacter ...

Embodiment 2

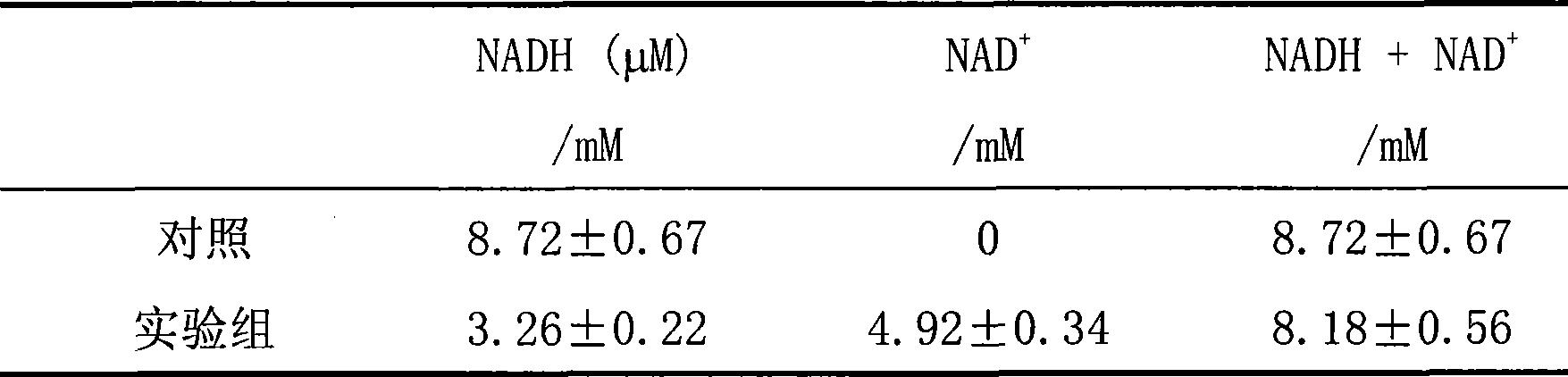

[0037] Example 2, Enterobacter aerogenes converts NADH into NAD +

[0038] 1) Culture Enterobacter aerogenes

[0039] Enterobacter aerogenes (Enterobacter aerogenes) IAM1183 was inserted into the culture medium (glucose 15g / L, peptone 5g / L, K 2 HPO 4 14g / L, KH 2 PO 4 6g / L, (NH 4 ) 2 SO 4 2g / L, MgSO 4 ·7H 2 O 0.2g / L), 37°C, 170rpm air bath shaker culture.

[0040] Take 60ml of Enterobacter aerogenes IAM1183 cultured in an aerobic shake flask for 12 hours, centrifuge at 10,200×g at 4°C for 5 minutes, and collect Enterobacter aerogenes cells.

[0041] 2) NADH is converted to NAD +

[0042] Wash the Enterobacter aerogenes cells in step 1) three times with 50 mM triethanolamine buffer (TEA) at pH 9, then resuspend in 50 mM triethanolamine buffer (TEA) at pH 9, and adjust the cell concentration to OD 600 1.0, add NADH, make the final concentration of NADH 10mM, 50 ℃, 170rpm culture, as the experimental group.

[0043] NADH was added with 50 mM triethanolamine buffer...

Embodiment 3

[0050] Example 3, Enterobacter aerogenes converts NADH into NAD +

[0051] 1) Culture Enterobacter aerogenes

[0052] Enterobacter aerogenes (Enterobacter aerogenes) IAM1183 was inserted into the culture medium (glucose 15g / L, peptone 5g / L, K 2 HPO 4 14g / L, KH 2 PO 4 6g / L, (NH 4 ) 2 SO 4 2g / L, MgSO 4 ·7H 2 O 0.2g / L), 37°C, 170rpm air bath shaker culture.

[0053] Take 60ml of Enterobacter aerogenes IAM1183 cultured in an aerobic shake flask for 12 hours, centrifuge at 10,200×g at 4°C for 5 minutes, and collect Enterobacter aerogenes cells.

[0054] 2) NADH is converted to NAD +

[0055] Wash the Enterobacter aerogenes cells in step 1) three times with 50 mM triethanolamine buffer (TEA) at pH 4, then resuspend in 50 mM triethanolamine buffer (TEA) at pH 4, and adjust the cell concentration to OD 600 to 0.8, NADH was added to make the final concentration of NADH 20 μM, cultured at 4°C, 170 rpm, as the experimental group.

[0056] Add NADH with pH 4 50 mM trietha...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com