Steam-liquid separator for crude oil extraction and evaporation

A technology of liquid separator and evaporating steam, which is applied in the direction of fat oil/fat production and fat generation, which can solve the problems that cannot satisfy the complete separation of solvent and crude oil, increase the difficulty of working in the salad oil workshop, and reduce the radius of rotation, etc., to eliminate Boiling pot phenomenon, easy control of evaporation operation, and the effect of increasing the radius of centrifugal rotation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] Now take the vapor-liquid separator suitable for 200T crude oil production line as an example to specifically illustrate the characteristics and design points of the vapor-liquid separator of the present invention.

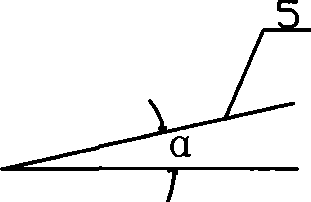

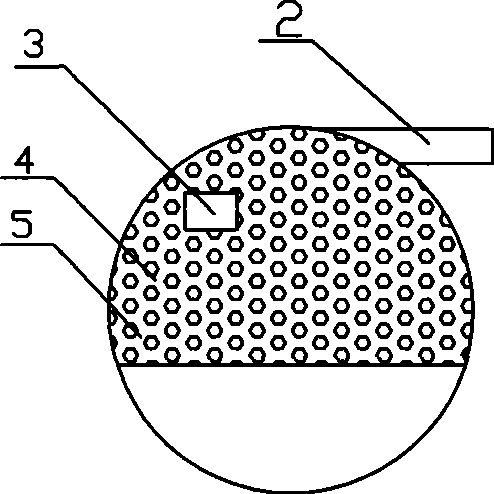

[0029] Such as figure 1 , figure 2 , image 3 and Figure 4 As shown, the gas-liquid separator includes a cylinder body 1, a feed inlet 2, an air outlet 7 and a discharge outlet 8. The cylinder body 1 is cylindrical, with a radius of 0.6 meters and a height of 1 meter. Install sieve plate 5 at 10 centimeters of the lower edge of feed opening 2, the shape of sieve plate 5 is arched, and the sagittal height of arch is 0.6 meter, and radius is 0.6 meter, and the included angle α=5 ° of sieve plate 5 and horizontal direction; The gas riser 3 on the sieve plate 5 is located at the front of the liquid inlet direction and is close to the side wall of the cylinder. The gas riser 3 is a straight tube with a rectangular cross section. The rectangular length of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com