Organosilicon slag slurry treatment method and apparatus thereof

A technology of organosilicon slag slurry and treatment method, which is applied in the fields of organic chemistry, organic silicon compounds, chemical instruments and methods, etc., can solve the problems of effective resource waste, fire or explosion, hidden dangers, etc., so as to save treatment costs and solve environmental protection problems. and safety concerns

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

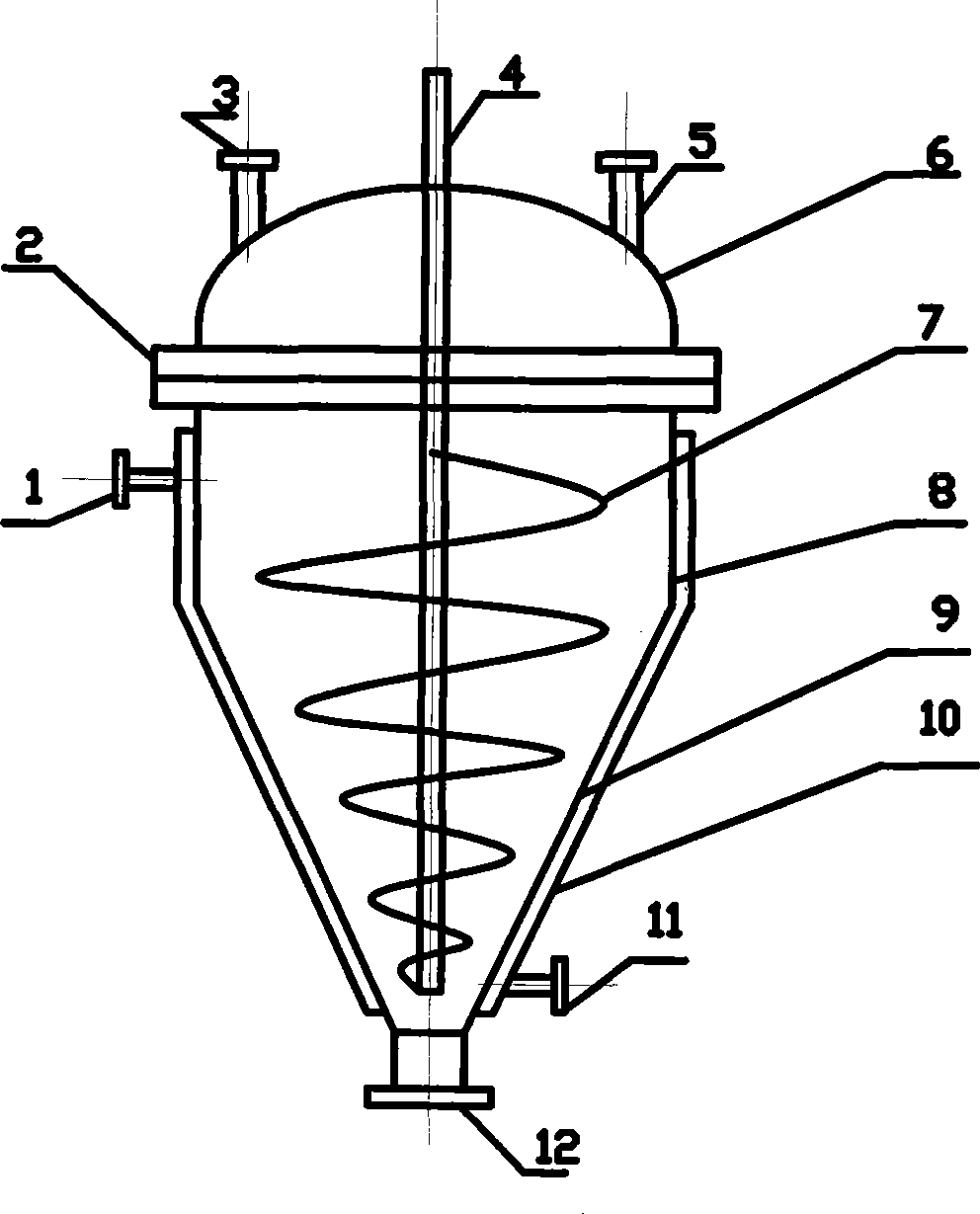

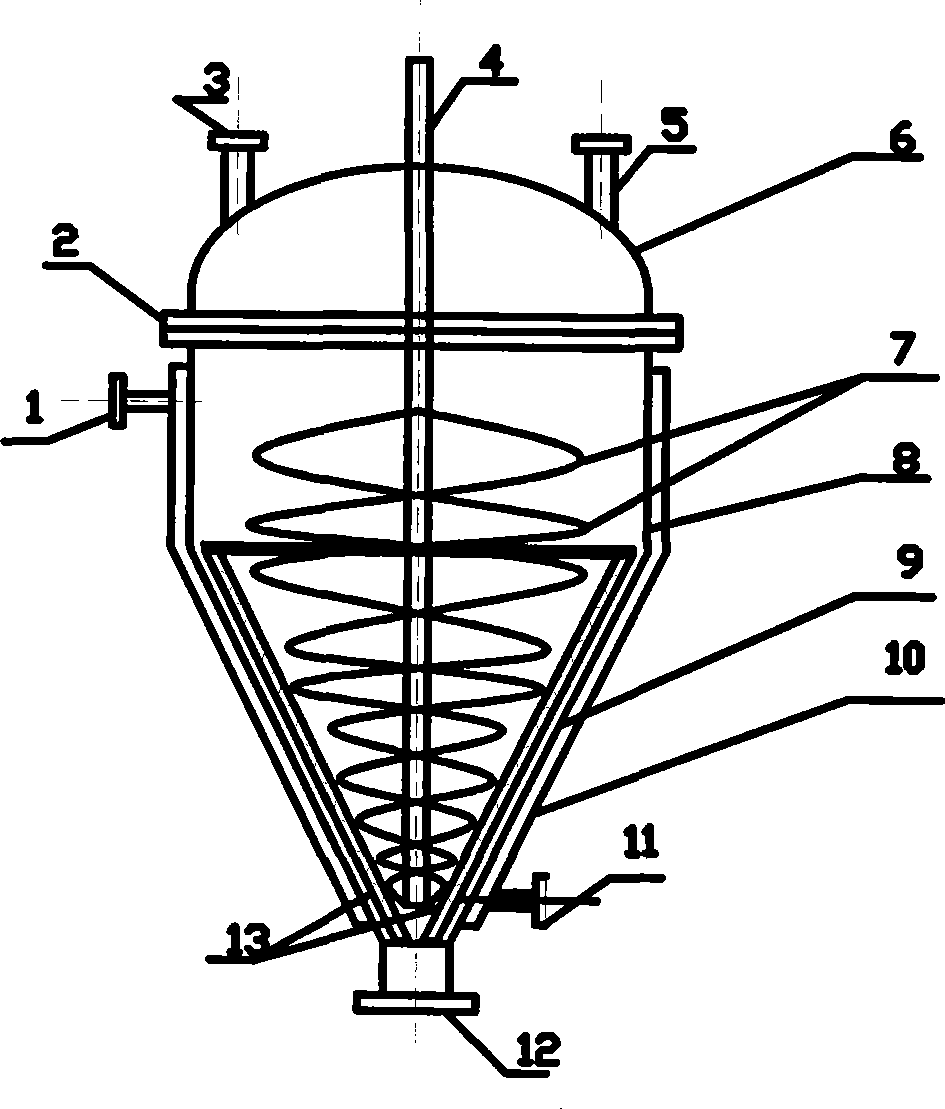

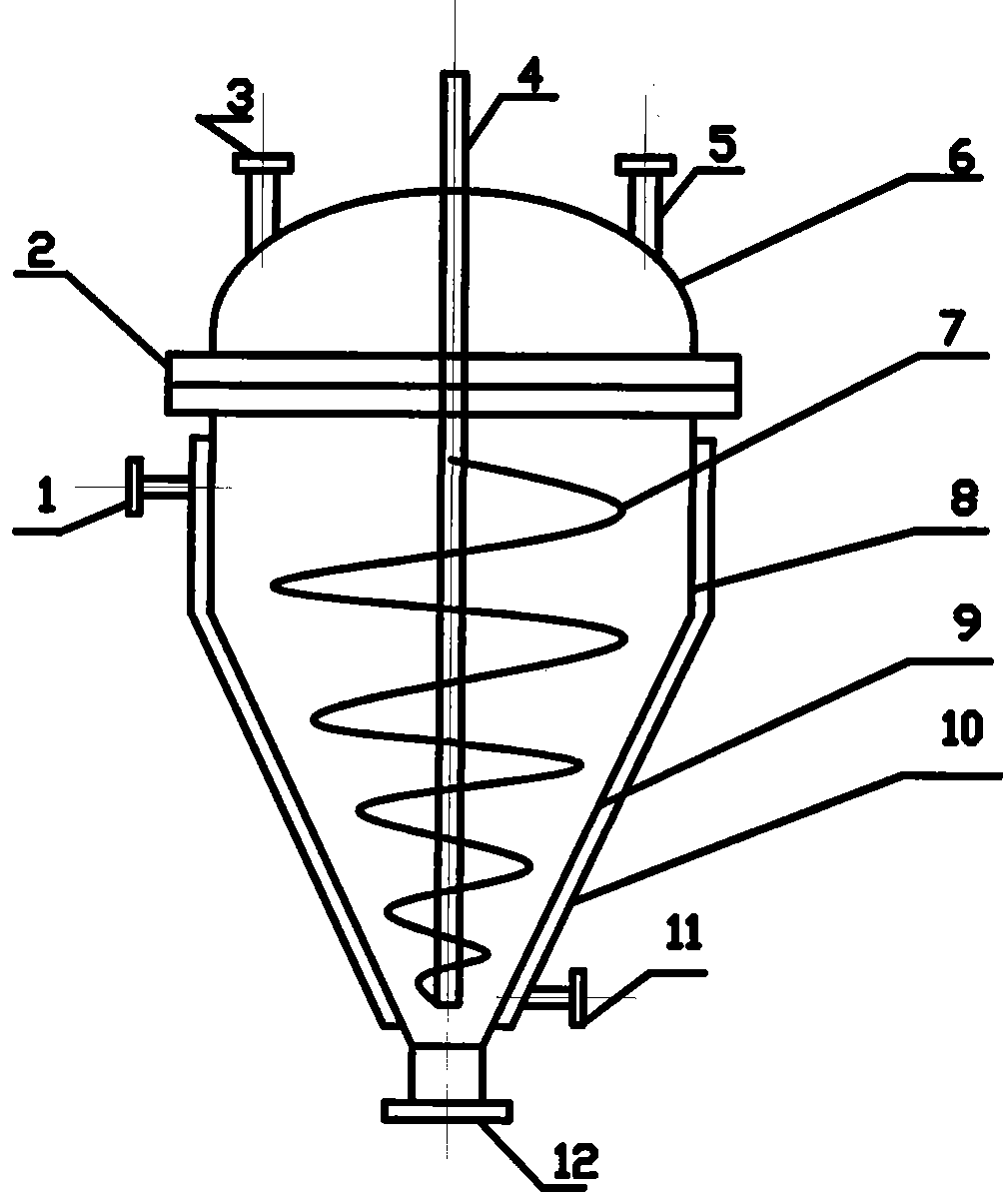

Image

Examples

Embodiment 1

[0016] Preheat the 1000kg slurry (solid content 37.64%, high boiling matter 62.36%) from the reboiler of the methyl chlorosilane monomer synthesis washing tower to 210°C through the preheater, add it to the conical evaporator, and start the single screw belt The speed of the stirrer was 12 rpm, the temperature in the kettle was controlled at 250-260°C, and the operation was carried out under normal pressure for 5 hours. The results are shown in Table 1.

[0017] Table 1 The obtained product weight

[0018]

Embodiment 2

[0020] The 2000kg slurry (solid content 35.34%, high boiler 64.66%) from the reboiler of the methyl chlorosilane monomer synthesis washing tower is preheated to 200°C by the preheater, added to the conical spiral evaporator, and the double screw evaporator is started. The speed of the agitator is 10 rpm, the temperature in the kettle is controlled at 230-240°C, and the operation is carried out under normal pressure for 5 hours. The results are shown in Table 2.

[0021] Table 2 The weight of the product obtained

[0022]

PUM

| Property | Measurement | Unit |

|---|---|---|

| angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com