Methanol synthesis catalyst, method for producing such catalyst and method for producing methanol

A methanol synthesis and manufacturing method technology, applied in the direction of catalyst activation/preparation, organic chemical methods, organic compounds/hydrides/coordination complex catalysts, etc., can solve problems such as increased costs, reduced activity, unrealistic, etc., to achieve low cost Production, the effect that the reduction degree of catalyst activity is low

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

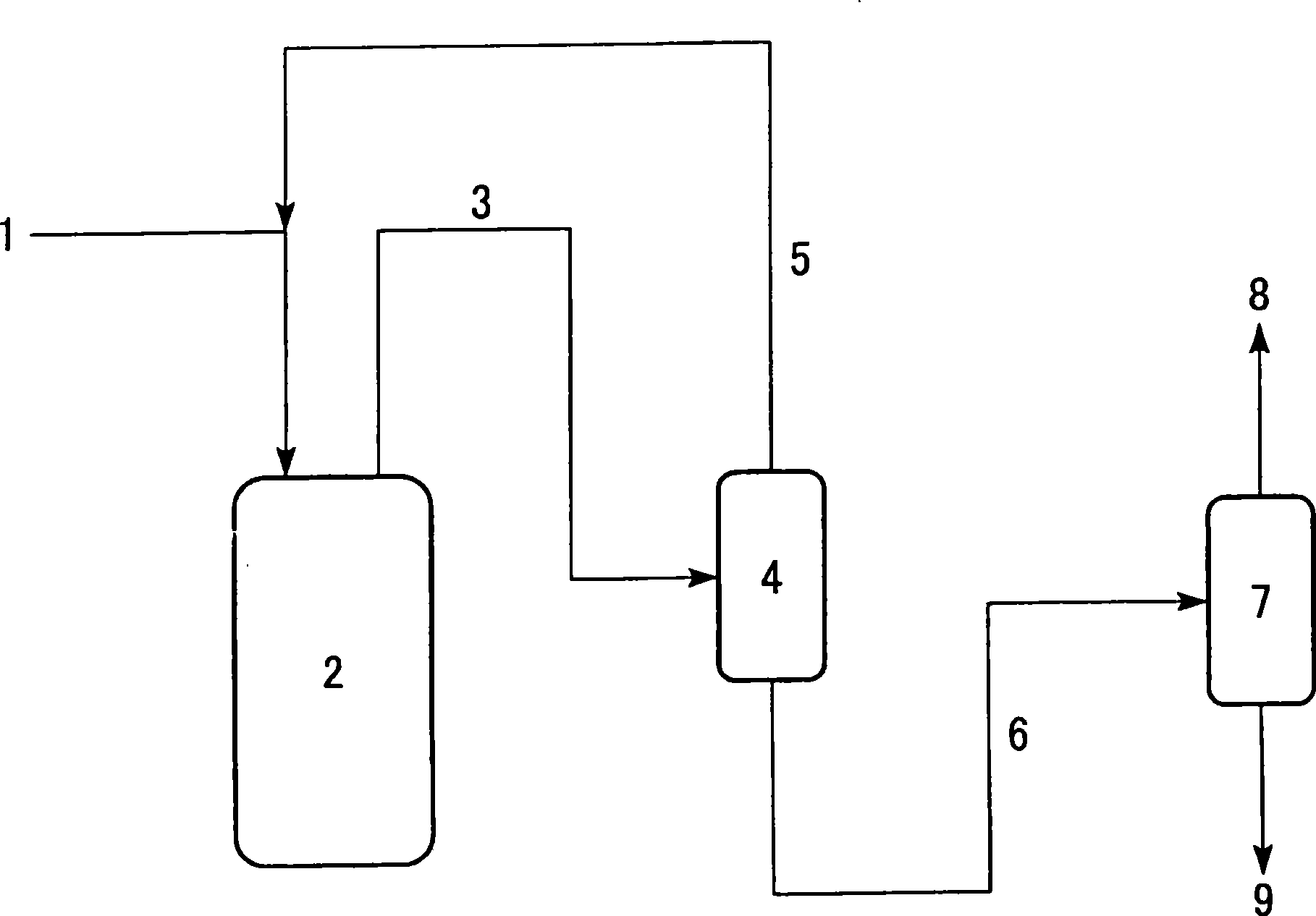

Method used

Image

Examples

Embodiment 1

[0071] Using an autoclave with an inner volume of 50ml, add 2.5mmol of potassium formate to 10ml of ethanol as a solvent, with Cu(NO 3 ) 2 ·3H 2 O, Mg(NO 3 ) 2 ·6H 2 Cu / MgO was prepared by co-precipitation method while maintaining the pH at 10.0 as a raw material x , add 1g by the Cu / MgO x Gradually impregnated loaded with Na 2 CO 3 (18.7% by mass), Cu / MgO formed by Pd (0.25% by mass) x / Na 2 CO 3 (18.7% by mass) / Pd (0.25% by mass) catalyst, filled with 5MPa synthesis gas (CO: 32.40% by volume, H 2 : 64.58% by volume, Ar: 3.02% by volume), reacted at 160° C. for 5 hours, and the reaction product was analyzed by gas chromatography. The yield of methanol was 75.2 mmol and the yield of ethyl formate was 2.1 mmol. and Pd-unloaded Cu / MgO described in Comparative Example 1 described later x / Na 2 CO 3 (18.7% by mass), exhibited very high activity.

Embodiment 2

[0073] The reaction was carried out by the method described in Example 1 except that the reaction temperature was 180°C. The yield of methanol was 56.4 mmol and that of ethyl formate was 1.1 mmol.

Embodiment 3

[0075] The reaction was carried out by the method described in Example 1 except that the reaction temperature was 140°C. The yield of methanol was 20.7 mmol and that of ethyl formate was 2.2 mmol.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com