Preparation method of photo-catalytic nano wood-plastic board

A technology of photocatalyst and nanomaterials, applied in the direction of flat products, devices for coating liquid on the surface, application, etc., can solve the problems of poor effect, pollution of wooden furniture and wooden floors, no antibacterial, etc., to solve moldy objects , strong lethal effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0049] Put 50kg of crop straw powder into a horizontal mixer with heating, add 2kg of t1 series aluminum-zirconium coupling agent, set the temperature at 110°C, and stir for 2 hours; put the stirred crop straw powder into a high-speed kneader, And add PVC resin 100kg and related additives (tribasic lead sulfate 6kg, dibasic lead phosphite 2kg, zinc stearate 0.7kg, calcium stearate 0.6kg, regulator 6kg, ACR 2kg, lubricating agent) 2kg foaming agent, 0.4kg foaming agent, talcum powder 6kg), stir at 100°C for 10 minutes at high speed, discharge the mixed material to the low-speed mixer, continue stirring to normal temperature, and then discharge; the discharged mixture passes through the plate Extrusion molding machine, sheet mold, vacuum cooling and shaping, two-roll calendering and shaping, traction, and cutting to length to obtain wood-plastic sheets; the photocatalyst nano-TiO 2 It is sprayed on the surface of the wood-plastic board to form a closed and continuous photocataly...

Embodiment 2

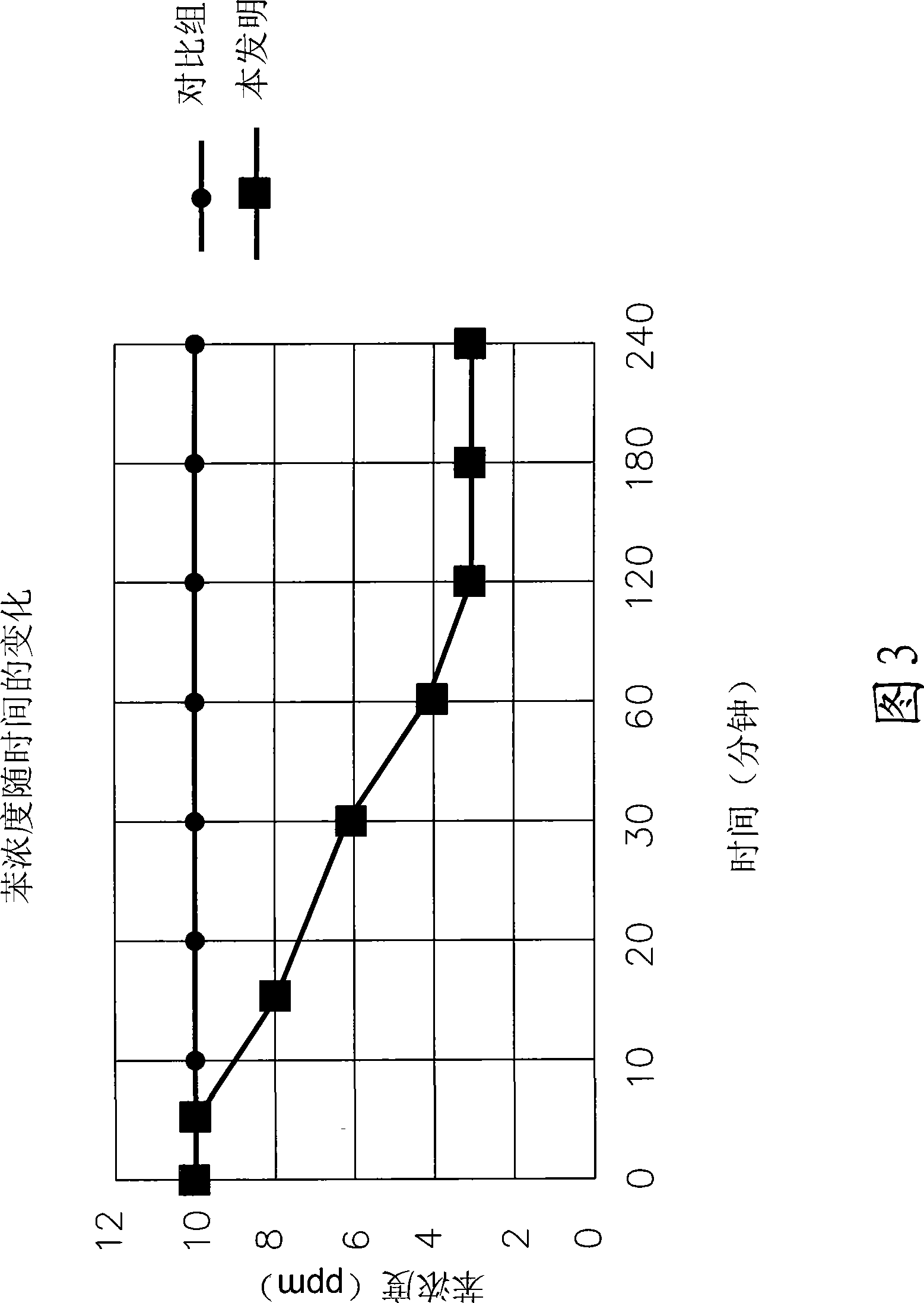

[0051] Put 100kg of wood chips into a horizontal mixer with heating, add 4kg of t1 series aluminum-zirconium coupling agent, set the temperature at 120°C, and stir for 2.5 hours; put the stirred wood chips into a high-speed kneader, Then add 100kg of PE resin and related additives (talcum powder 5kg, OPE wax 1.5kg, AC foaming agent 0.5kg) in sequence, stir at 110°C for 15 minutes at high speed, discharge the mixed material into a low-speed mixer, and continue After stirring to normal temperature, the material is discharged; the discharged mixture is passed through a sheet extrusion molding machine, a sheet mold, vacuum cooling and setting, two-roll calendering and setting, traction, and cut to length to obtain a wood-plastic sheet; the photocatalyst nano ZnO is sprayed on the A closed and continuous photocatalyst nano-layer is formed on the surface of the wood-plastic board, and the two are tightly connected together to obtain a photocatalyst nano-wood-plastic board. After tes...

Embodiment 3

[0053] Put 80kg of cotton husk powder into a horizontal mixer with heating, add 3.5kg of t1 series aluminum-zirconium coupling agent, set the temperature at 110°C, and stir for 2 hours; put the stirred cotton husk powder into high-speed kneading Add 160kg of PP resin and related additives (2.2kg of lubricant, 0.2kg of foaming agent, 10kg of talcum powder) in sequence, stir at 110°C for 10 minutes at high speed, and discharge the mixed material to the low-speed mixer , after continuing to stir to normal temperature, discharge the material; the discharged mixture passes through the sheet extrusion molding machine, sheet mold, vacuum cooling and shaping, two-roller calendering and shaping, traction, and cut-to-length to obtain wood-plastic sheets; the photocatalyst nano ZrO 2 It is sprayed on the surface of the wood-plastic board to form a closed and continuous photocatalyst nano-layer, and the two are tightly connected together to obtain a photocatalyst nano-wood-plastic board. ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com