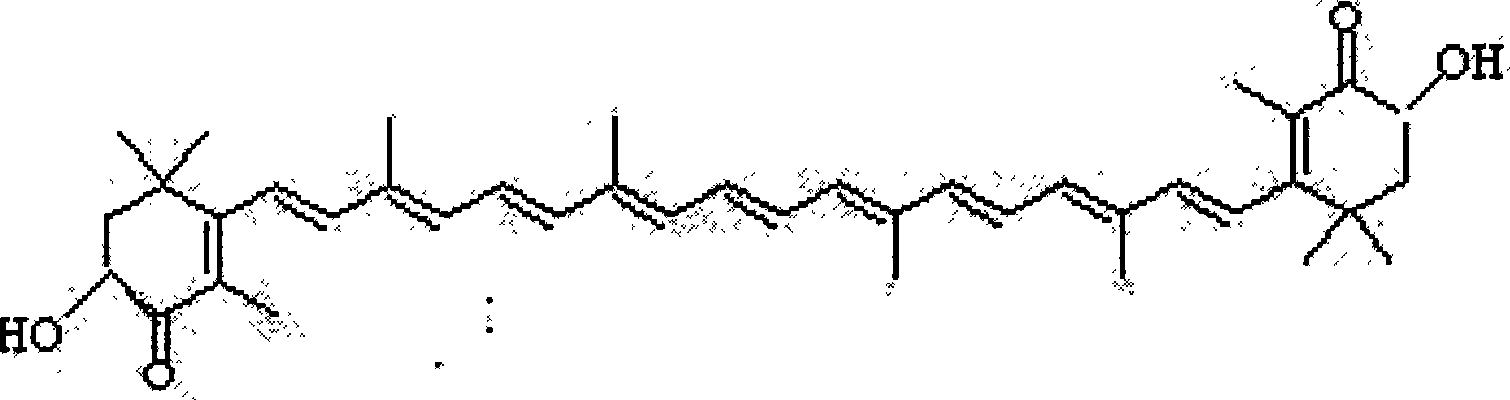

Astaxanthin extraction method

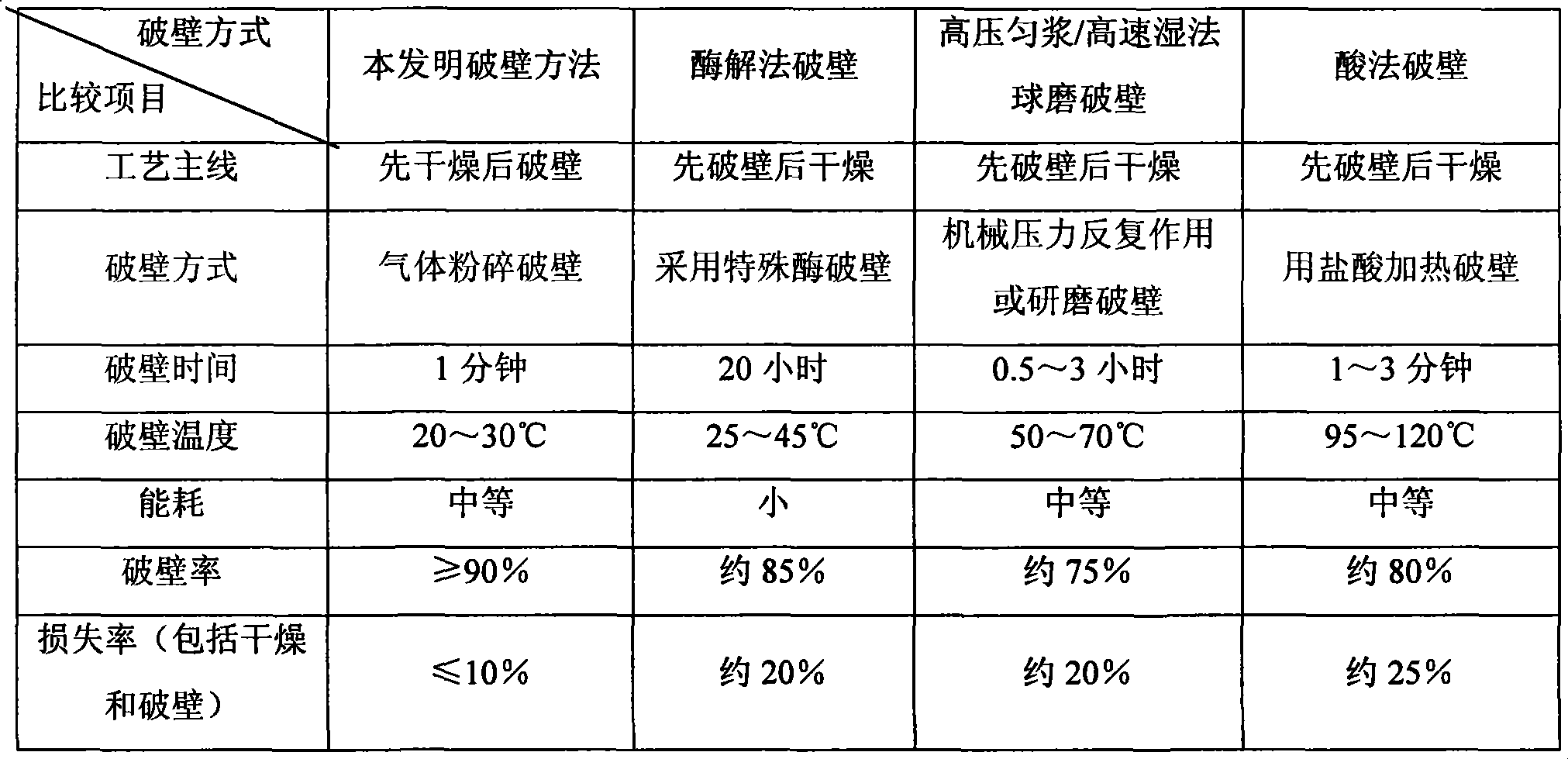

An extraction method, the technology of astaxanthin, which is applied in the direction of organic chemistry, can solve the problems of affecting food safety, taking several hours, and high cost, and achieve the effects of avoiding high-temperature oxidation loss, short wall breaking time, and high wall breaking rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

[0027] 1. Using glucose or fructose syrup and yeast extract as raw materials to ferment Rhodotorula paffia astaxanthin, fermentation conditions: temperature 20-24°C, pH 4.0-5.0, fermentation period 4 days;

[0028] 2. After cooling to 15°C after fermentation, feed into LW424Y horizontal screw unloading sedimentation centrifuge to collect yeast sludge by centrifugation. The moisture content of the obtained yeast sludge should not be higher than 85%, and the loss rate of the whole centrifugal separation process should be controlled at 0.5%. the following;

[0029] 3. Use a screw pump to drive the yeast mud into the GZ-200 high-speed centrifugal spray dryer. Before feeding, adjust the inlet temperature to 160-200°C / outlet temperature to 50-80°C. The drying time of the material should not exceed 1 minute. After drying, it must contain Yeast powder with a moisture content of 5-10%, the loss rate of astaxanthin is 5-10%, and the yeast powder is collected with a black cloth bag at th...

example 2

[0032] 1. Using glucose or fructose syrup and yeast extract as raw materials to ferment Rhodotorula paffia astaxanthin, fermentation conditions: temperature 20-24°C, pH 4.0-5.0, fermentation period 4 days;

[0033] 2. After the fermentation is finished, cool to 15°C and put the material into the LW424Y horizontal screw discharge sedimentation centrifuge to collect the yeast sludge by centrifugation. The moisture content of the yeast sludge obtained should not exceed 85%, and the loss rate of the whole centrifugal separation process should be controlled below 0.5%. ;

[0034] 3. Use the screw pump to drive the yeast mud into the WZL-900 continuous microwave vacuum dryer. Before feeding, adjust the temperature of the cavity to 40-50 ° C, the vacuum degree to -0.080 MPa, and the drying time of the material for 30 minutes. After drying, it will contain moisture 5-10% of the yeast powder and astaxanthin loss rate of 5-10%, collect the yeast powder with a black cloth bag at the outl...

example 3

[0037] 1. Separate the Haematococcus pluvialis liquid to obtain algae mud with a water content of 75%. Use a screw pump to pump the algae mud into the GZ-200 high-speed centrifugal spray dryer. Before feeding, adjust the inlet temperature to 160-200°C / The outlet temperature is 50-80°C, and the drying time of the material does not exceed 1 minute. After drying, the algae powder with a moisture content of 5-10% and the loss rate of astaxanthin are 3-7%. Collect it with a black cloth bag at the outlet of the spray dryer Algae powder;

[0038] 2. The dried algae powder enters the LZQS-400 fluidized bed collision jet mill for wall breaking. The wall breaking temperature is 20-30°C and the gas pressure is 8-12 atmospheres. The wall breaking rate is 90%, and the astaxanthin loss rate is about 10%. The algae powder after wall breaking is directly vacuum-packed in an aluminum foil bag and stored in the dark at 2-8°C.

PUM

| Property | Measurement | Unit |

|---|---|---|

| loss rate | aaaaa | aaaaa |

| loss rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com