Single film hole aeration filter head

A single membrane and filter head technology, applied in the field of water treatment, can solve problems such as failure to meet process requirements, difficult maintenance, complex aeration system, etc., and achieve the effects of uniform gas distribution, easy maintenance and high aeration efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be further described below in conjunction with the accompanying drawings and examples, but the embodiments of the present invention are not limited thereto.

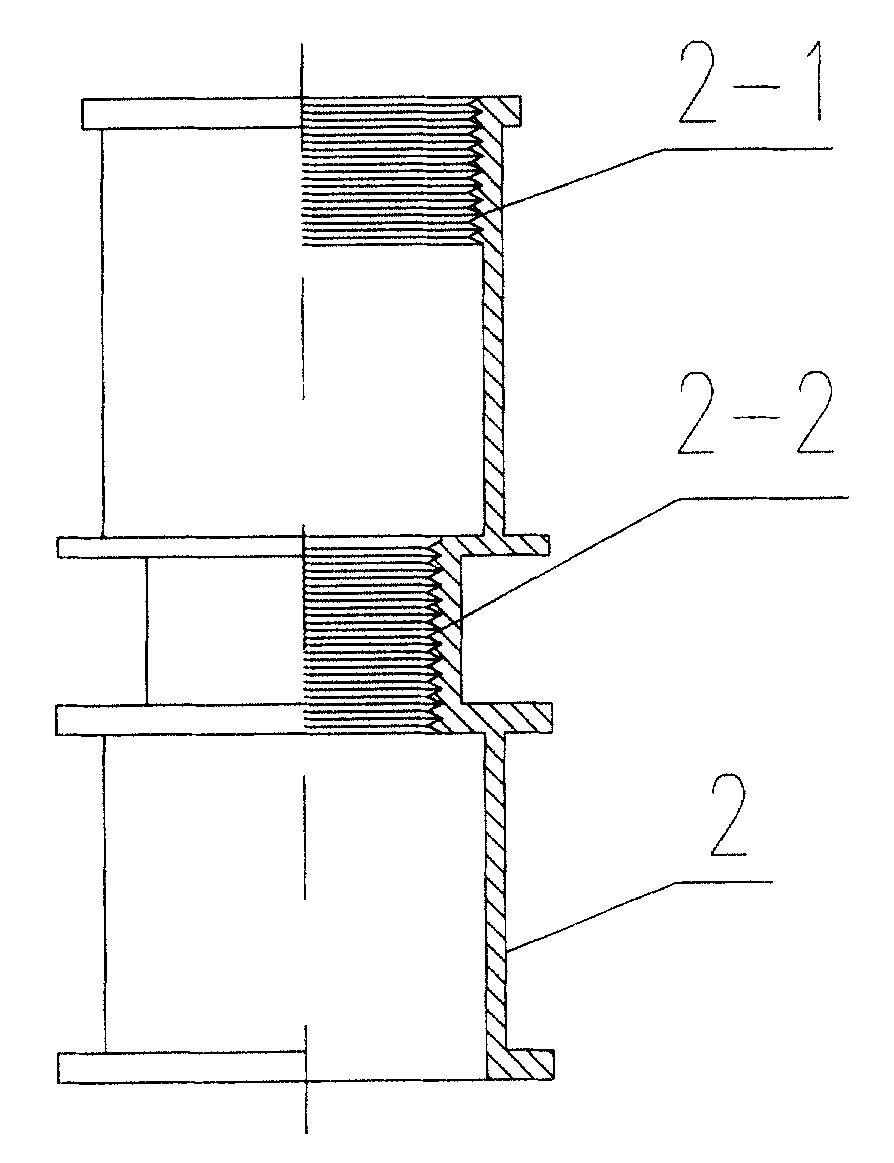

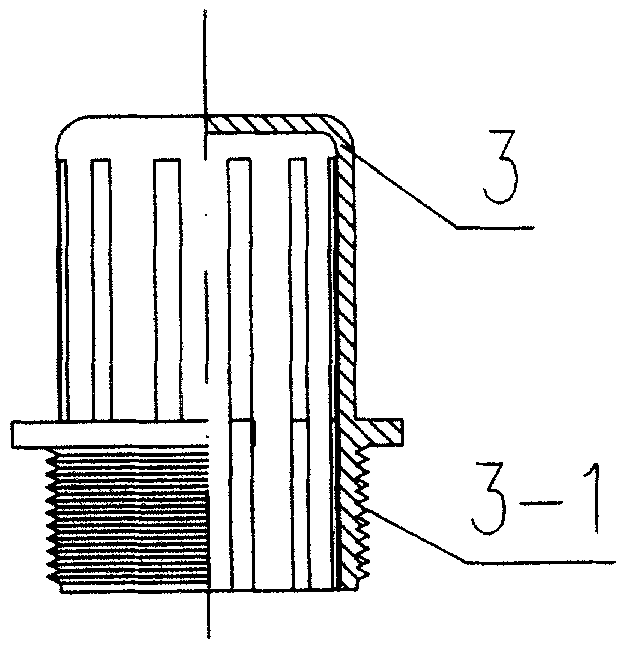

[0025] Such as figure 1 , 2 , 3 and 4, the single membrane hole aeration filter head includes a hollow single membrane hole filter handle 1, a pre-embedded filter sleeve 2 and a filter cap 3. The single membrane hole filter handle 1 is connected with the internal thread 2-2 of the embedded part 2 through its external thread 1-1; the embedded part 2 is fixed on the filter plate by pouring concrete; the filter cap 3 is connected with its external thread 3-1 Connect with the internal thread 2-1 of the embedded part 2. The air distribution hole 1-5 of the single membrane hole filter handle 1 has a pore diameter of ¢2~3mm, and an aeration membrane hole device 1-3 is arranged at a distance of 50~200mm above, and the aeration membrane hole device 1-3 is located under the bottom of the filter...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com