Wing with high intensity and high stiffness

A high-stiffness, high-strength technology applied to wings. In this field, it can solve the problems of uncoordinated deformation of the wing handle and the wing, low machining efficiency of the wing handle, poor stiffness and strength of the wing, etc., and achieve the effect of low manufacturing technology requirements, coordinated deformation, and avoiding instability and warping

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

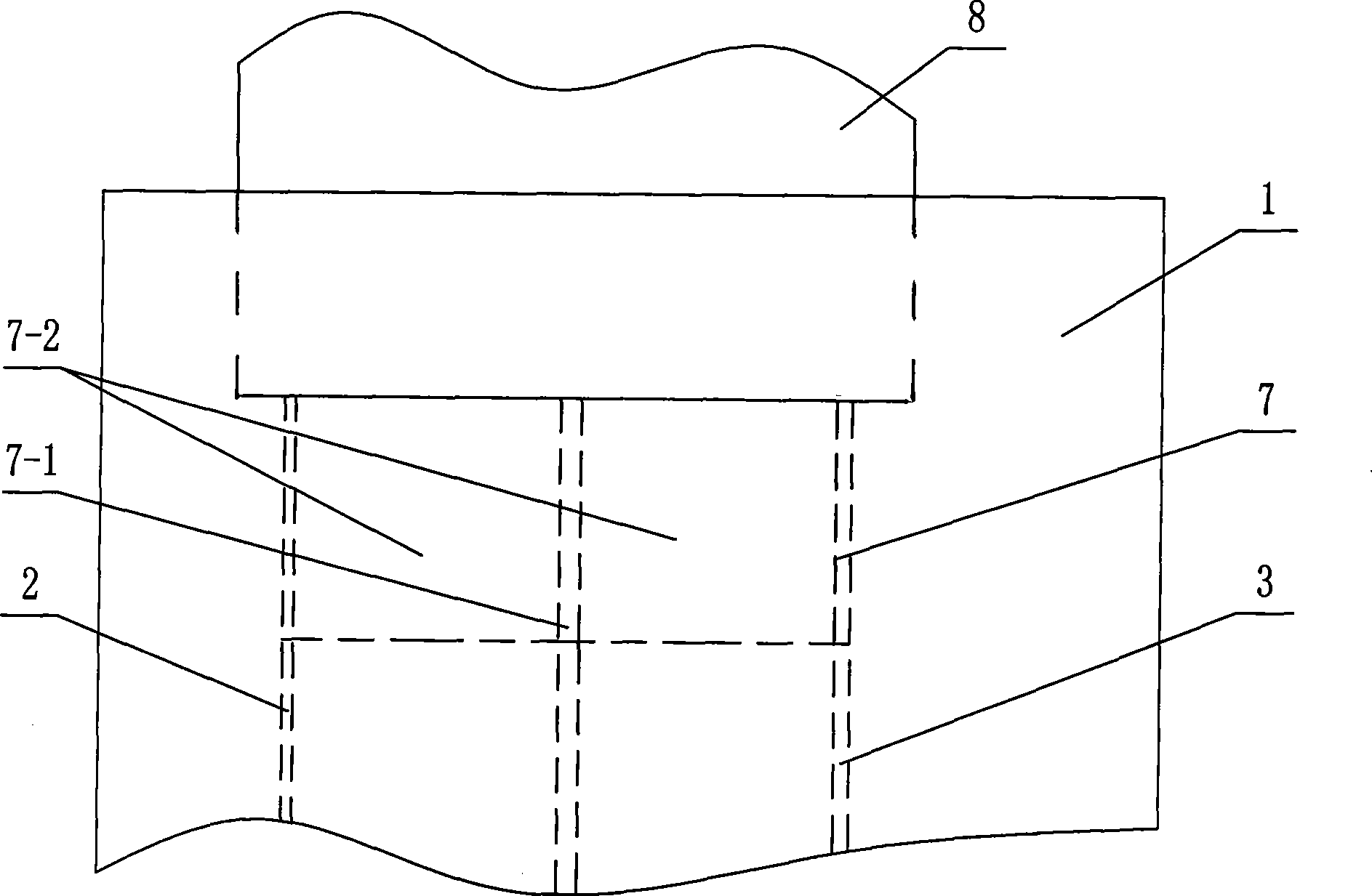

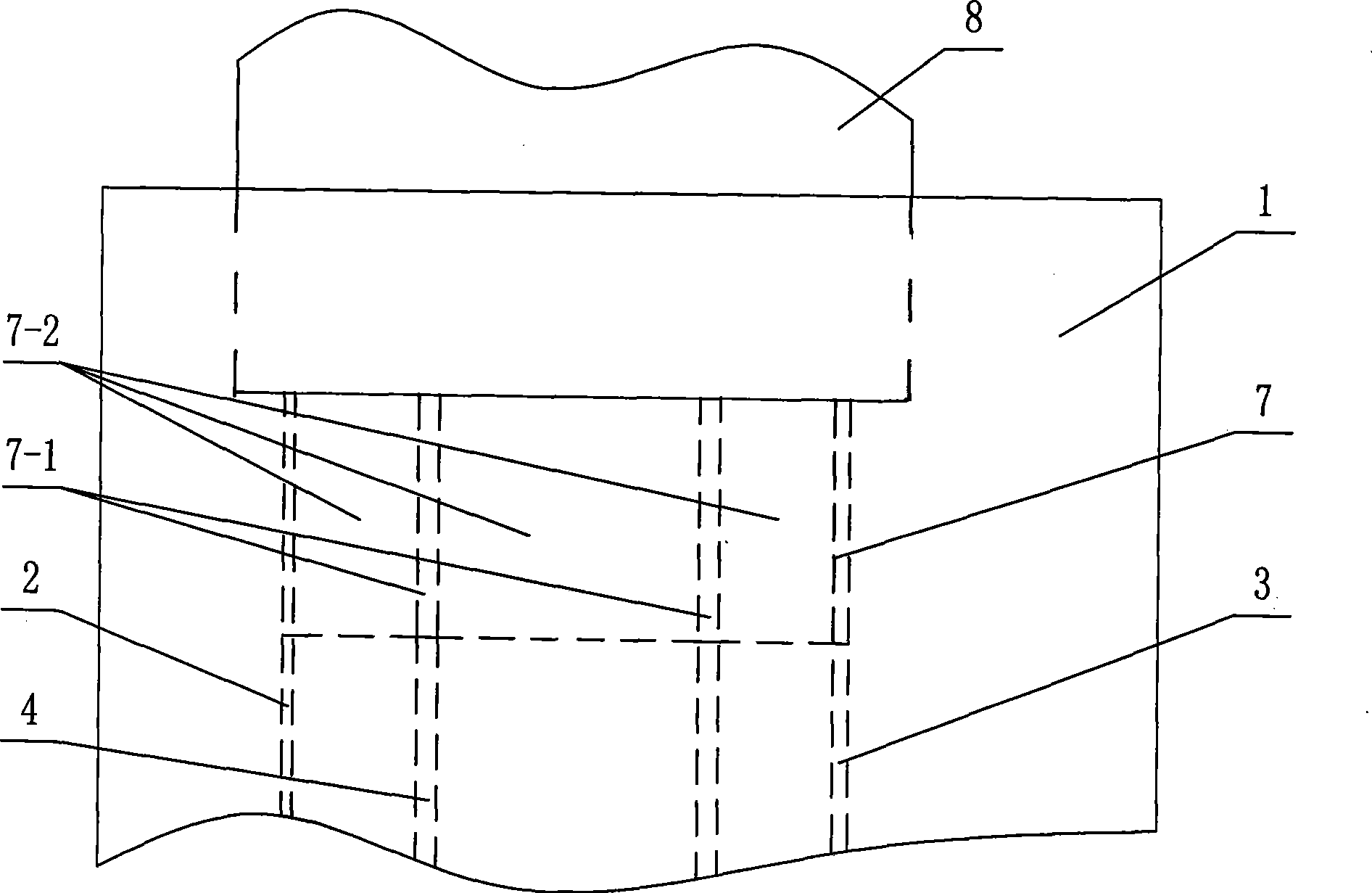

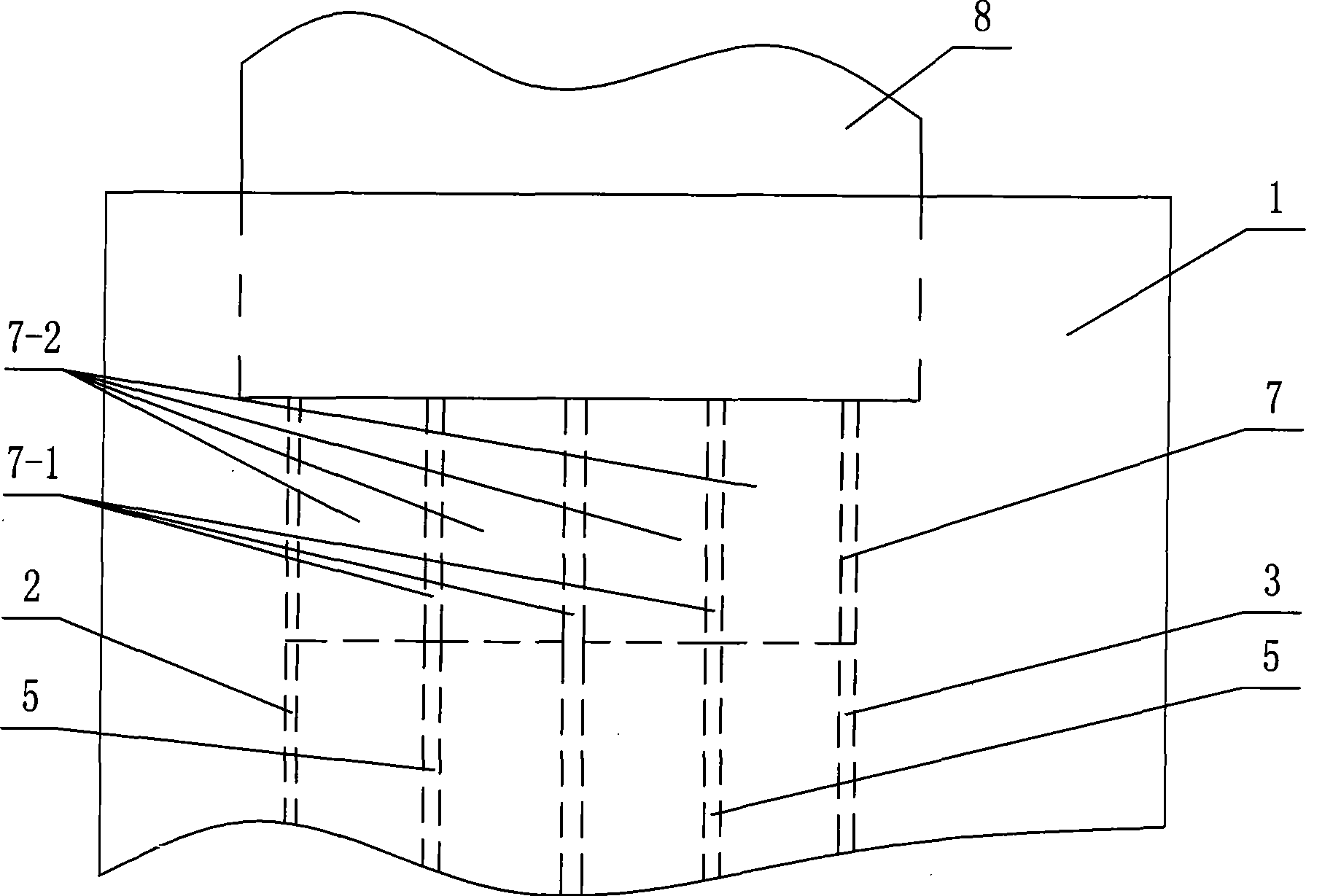

[0010] Specific implementation mode one: combine figure 1 , Figure 4 and Figure 7 Describe this embodiment, this embodiment is made up of fin and metal wing handle, and described fin is made up of composite material skin 1, first core pipe 2 and second core pipe 3, and the vertical of described first core pipe 2 The straight face is affixed to the vertical surface of the second core pipe 3 to form a reinforcement body, and the composite skin 1 is coated on the outer wall of the reinforcement body formed by the first core pipe 2 and the second core pipe 3, so The metal wing handle is composed of a first-level step 7 and a second-level step 8, and the first-level step 7 and the second-level step 8 are integrated from bottom to top to form a two-step variable-section structure. There is a notch 7-1 on the step 7 to form two cores 7-2, and the two cores 7-2 of the first step 7 are respectively inserted into the first core tube 2 and the second core tube 3 Inside.

specific Embodiment approach 2

[0011] Specific implementation mode two: combination Figure 4 The present embodiment will be described. The width W of the cross-section of the fin of the present embodiment is 150 mm to 250 mm, and the thickness H is 20 mm to 30 mm. Such setting can more effectively avoid local instability and warping of the fins. Other compositions and connections are the same as in the first embodiment.

specific Embodiment approach 3

[0012] Specific implementation mode three: combination Figure 4 The present embodiment will be described. The composite material skin 1 of the present embodiment is a fiber-reinforced resin-based composite material skin. With such arrangement, the overall stiffness and strength of the fins are better. Other compositions and connections are the same as in the first embodiment.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Width | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com