Thermoplastic lining composite material vehicle tank

A composite material and thermoplastic technology, which is applied in the field of vehicle tanks, can solve the problems of poor corrosion resistance of tanks, high fuel consumption of vehicles, and heavy weight of metal tanks, and achieve the effect of reducing wall thickness, light weight, and design weight

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

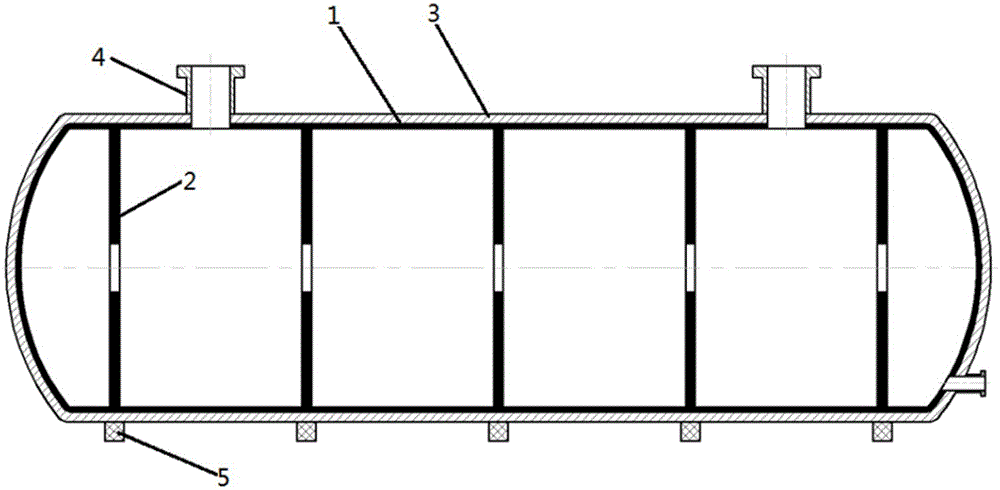

[0022] The present invention will be further described below in conjunction with the accompanying drawings.

[0023] A vehicle-mounted tank made of thermoplastic lining composite material, comprising an inner liner 1, an anti-shock partition 2, a structural layer 3, a flange 4, and a metal bracket 5. The vehicle-mounted tank is a circular or oval cylindrical structure, which is It is welded by polypropylene or polyethylene sheet, and there are 2-5 anti-shock partitions 2 along the section inside the tank. The anti-shock partition 2 is processed by polypropylene or polyethylene sheet, and passes through The tank is fixed by hot-melt welding, the top of the tank is provided with a flange 4, and the bottom is equipped with a metal bracket 5; the external cladding structure layer 3 of the tank body is made of a glass fiber reinforced thermosetting composite material layer, which is made by enveloping winding molding technology.

[0024] The total wall thickness of the inner lining...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Wall thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com