High-voltage motor parallel connection chopping and double-inversion speed-governing energy-saving controller

A high-voltage motor and inverter technology, applied in the direction of AC motor control, control system, regulating electrical variables, etc., can solve problems such as current sharing, and achieve the effect of reducing the influence of harmonics

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

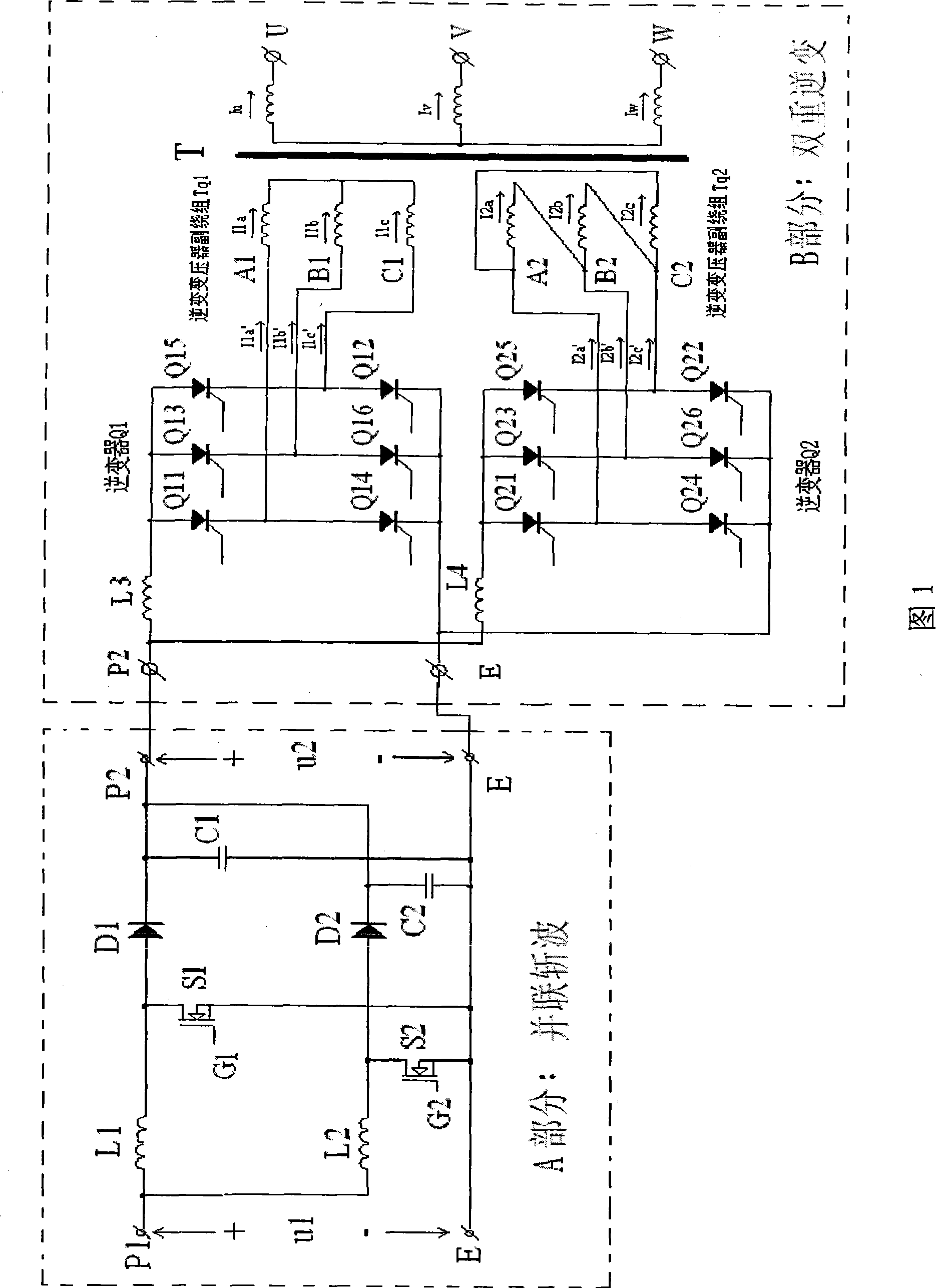

[0030] Referring to Fig. 1, the high-voltage motor parallel chopper and double inverter speed regulation energy-saving controller related to the present invention is composed of two parts, a parallel chopper and a double inverter.

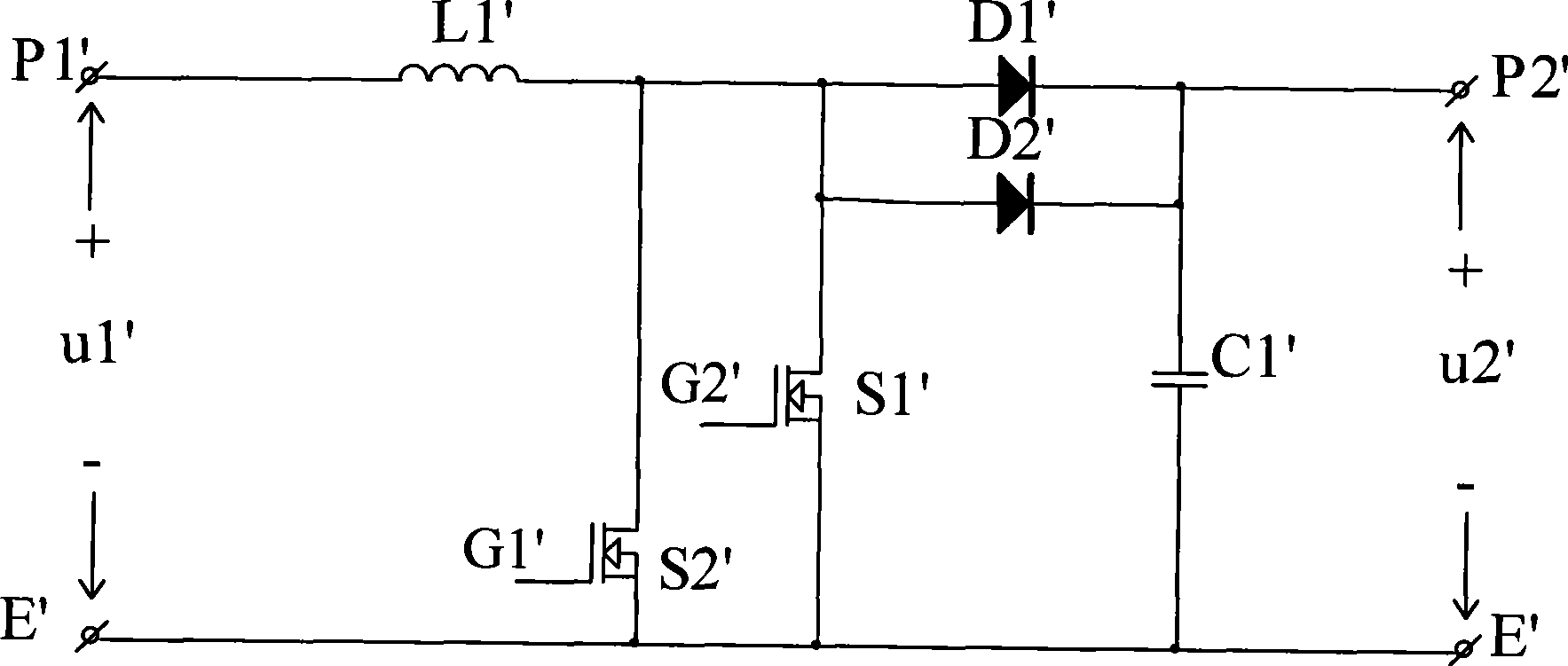

[0031]See part A of Figure 1: parallel chopper: the parallel chopper is composed of smoothing reactors L1, L2, insulated gate bipolar transistors S1, S2, fast recovery diodes D1, D2 and capacitors C1, C2. Its purpose is to increase the DC low voltage u1 input to the positive terminal (P1) and negative terminal (E) of the parallel chopper to the high voltage u2 required by the inverter. One end of the smoothing reactor L1 and L2 is connected in parallel to the input positive terminal (P1) of the parallel chopper, and the other end of the smoothing reactor L1 is connected to the positive end of the insulated gate bipolar transistor S1 and the anode of the fast recovery diode D1 The other end of the smoothing reactor L2 is connected to the positive en...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com