Soft belt LED lamp and manufacturing method and device thereof

A technology for an LED lamp and a manufacturing device, which is applied in the field of a soft-band LED lamp, a manufacturing method and a manufacturing device thereof, can solve the problems of light dispersion, inconsistent irradiation direction, uneven light and the like

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

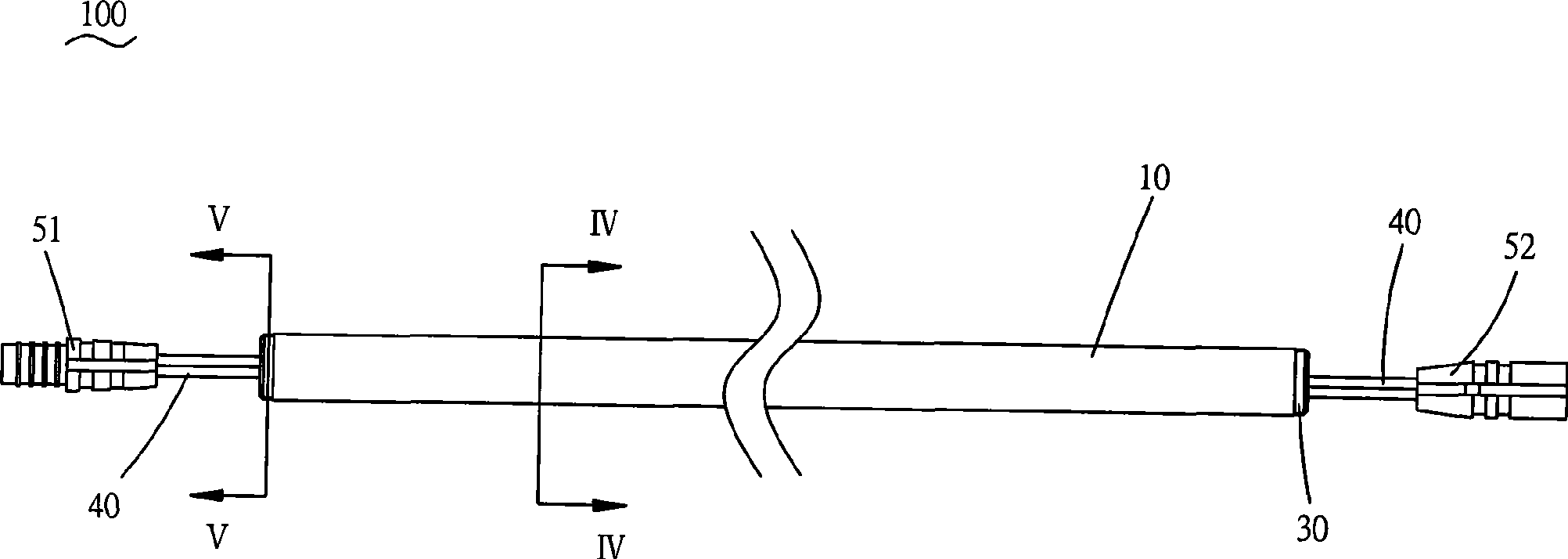

[0034] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments. The accompanying drawing descriptions of the components and parts in the figure are as follows:

[0035] figure 1 Figure 7 shows the flexible LED lamp provided by the present invention, and provides a manufacturing method dedicated to manufacturing the flexible LED lamp and a device for manufacturing the flexible LED lamp. In order to describe the technical content, structural features, achieved goals and effects of the present invention in detail, the following will be described in detail in conjunction with the implementation methods and accompanying drawings.

[0036] see figure 1 and figure 2 , a soft strip LED lamp 100, including a hollow strip-shaped shell 10, wherein: a strip-shaped circuit board 20 is installed in the shell 10, and a closed cover 30 is installed at both ends of the shell 10, and the circuit board through the closed c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com