Preparation of 6-O-beta-D- glucosyl-3,6,16,25-tetrahydroxy cycloartane

A technology of cyclopine and tetrahydroxy, which is applied in the field of medicine to achieve the effect of improving the yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] Embodiment 1 Preparation of solid fermented product:

[0031] Take astragalus dregs, crush them, pass through a 10-mesh sieve, add water to make the water content of astragalus dregs 52%, put them into 10 culture bottles, and sterilize at 120°C for 2 hours; after cooling, inoculate with 10% ganoderma lucidum, and adjust the temperature Ferment at 27°C for 32 days to obtain a solid fermented product; collect the solid fermented product, dry it at 60°C, measure the water content to 8%, and pulverize it.

Embodiment 2

[0032] Embodiment 2 Preparation of solid fermented product:

[0033] Take astragalus dregs, crush them, pass through a 10-mesh sieve, add water to make the water content of astragalus dregs 45%, put them into 10 culture bottles, and sterilize at 121°C for 1.5 hours; after cooling, inoculate with 5% ganoderma lucidum, and adjust the temperature Ferment at 25°C for 45 days to obtain a solid fermented product; collect the solid fermented product, dry it at 50°C, and pulverize it with a water content of 10%.

Embodiment 3

[0034] Embodiment 3 Preparation of solid fermented product:

[0035] Take astragalus dregs, crush them, pass through a 10-mesh sieve, add water to make the water content of astragalus dregs 60%, put them into 10 culture bottles, and sterilize them at 121°C for 2 hours; It is adjusted to 30°C and fermented for 40 days to obtain solid fermented product; the solid fermented product is collected, dried at 70°C, and pulverized with a water content of 6%.

[0036] The dried pulverized solid fermented product obtained in Example 1 is extracted and separated:

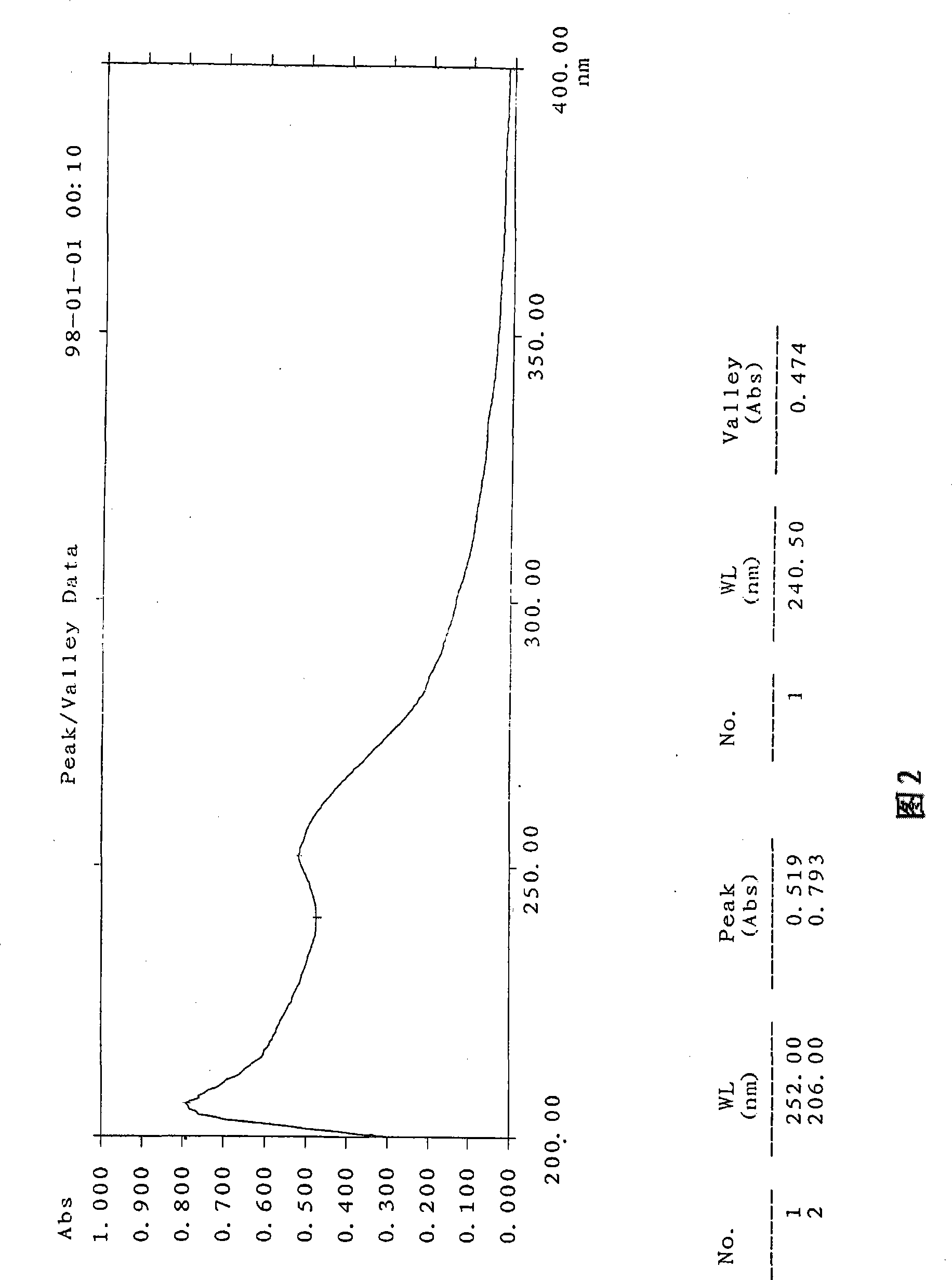

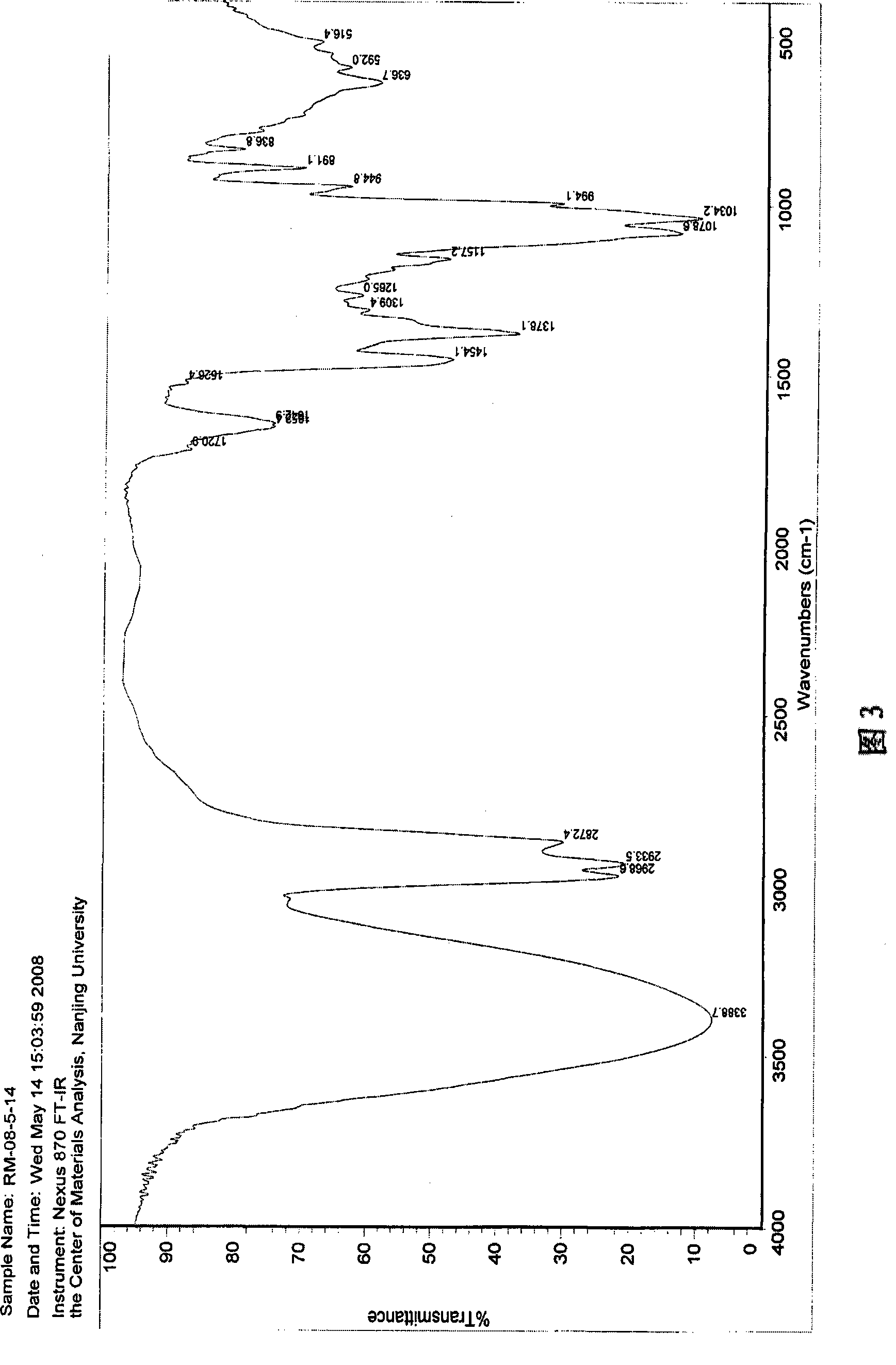

[0037] Take 1 kg of solid fermented product powder, add 70% ethanol extract to reflux extraction twice, each time for 2 hours, combine the 2 extracts, recover ethanol under reduced pressure to a thick paste, and obtain extract. Add an appropriate amount of water to dissolve the extract, shake and extract the aqueous solution for 3 times with n-butanol saturated with water, combine the n-butanol solution, wash fully with 1% NaO...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com