Welding method of high mirror-finished sheet in bridge support sliding panel assembly

A bridge support and welding method technology, which is applied in the field of welding, can solve the problems that the flatness of the mirror stainless steel plate cannot meet the requirements, the gap between the sliding plate and the mirror stainless steel sheet is large, and the welding deformation is large, so as to reduce the welding heat input. Ease of popularization and application, and the effect of increased yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The present invention will be described in further detail below in conjunction with accompanying drawing description and specific embodiment:

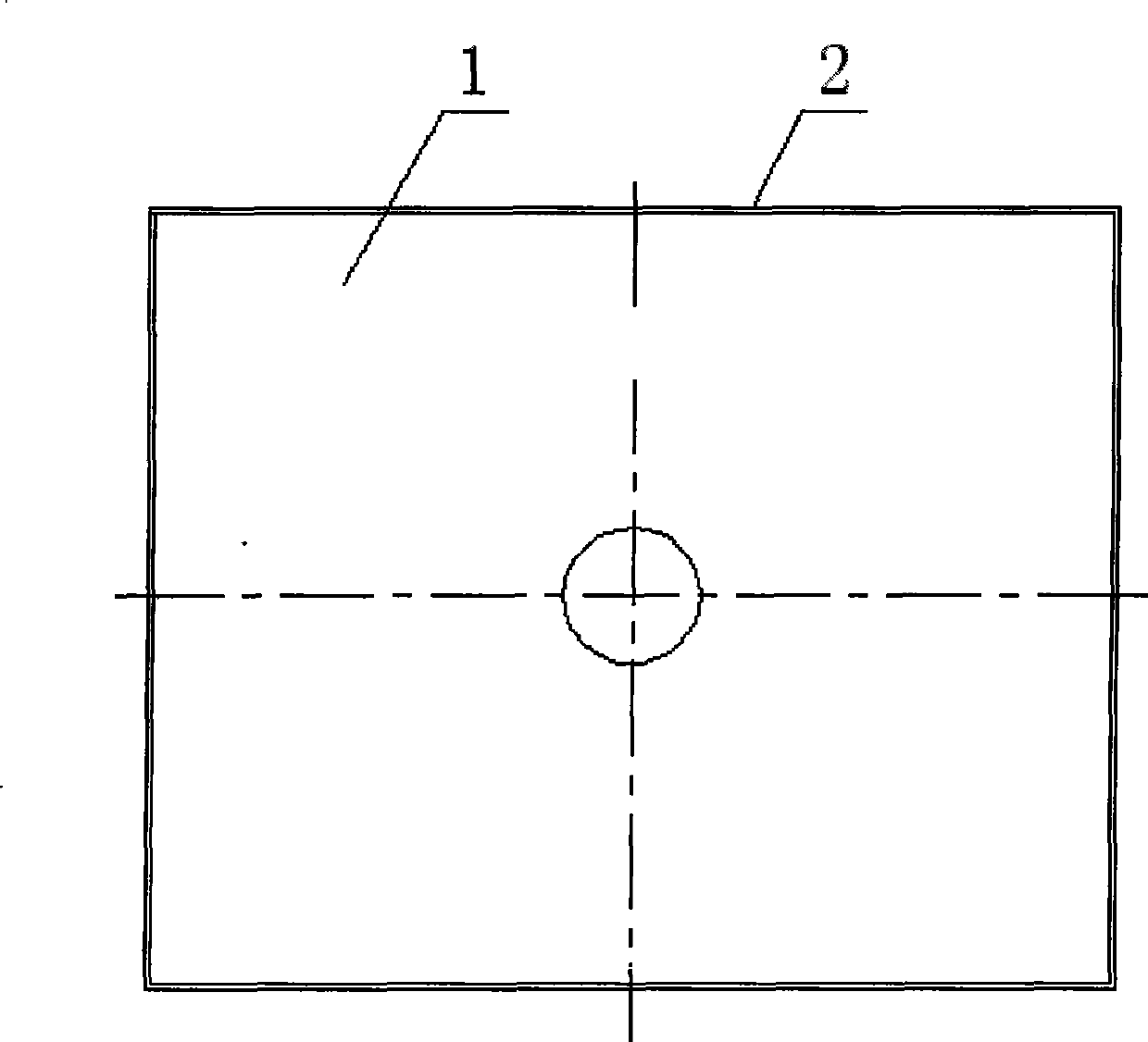

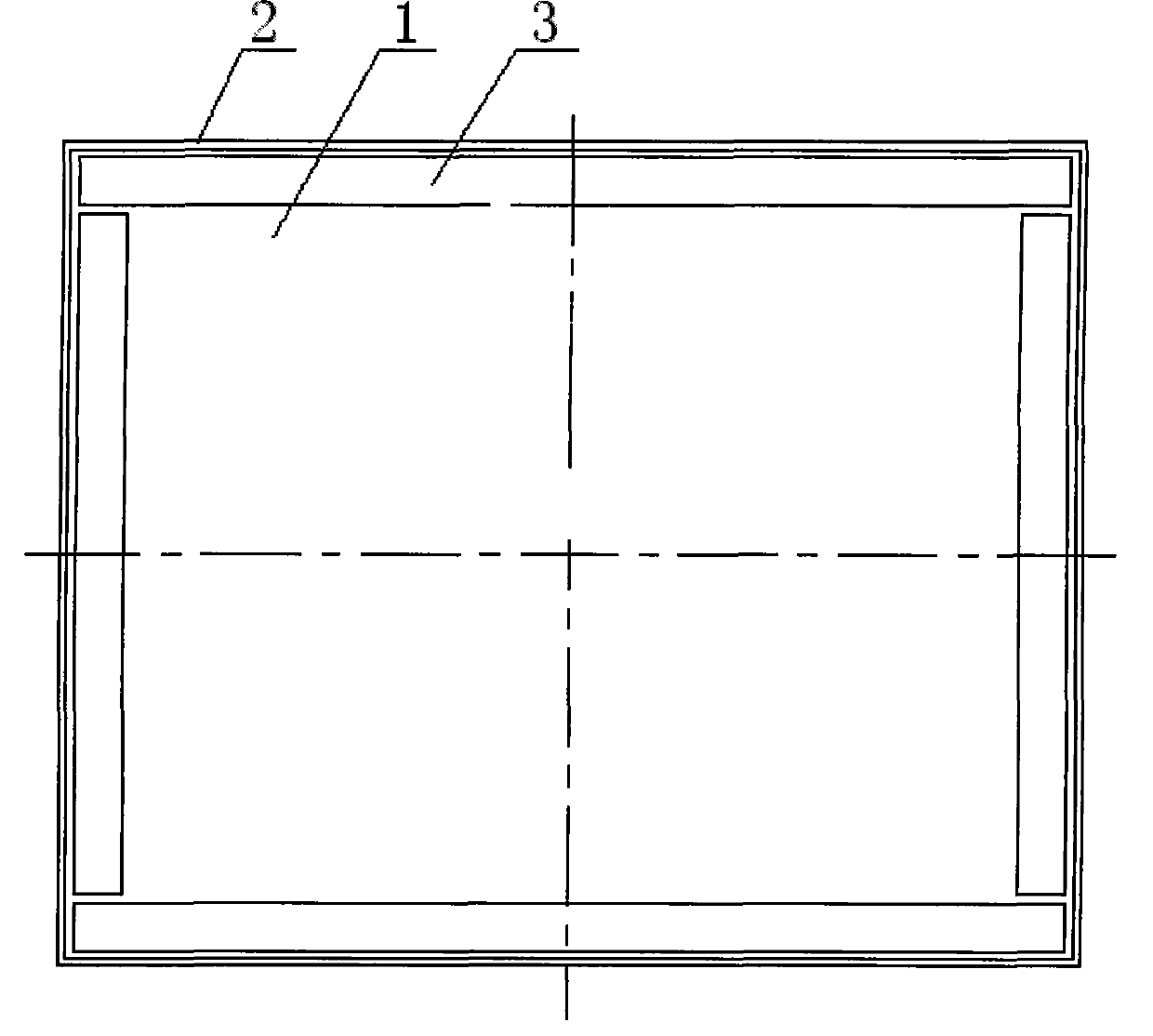

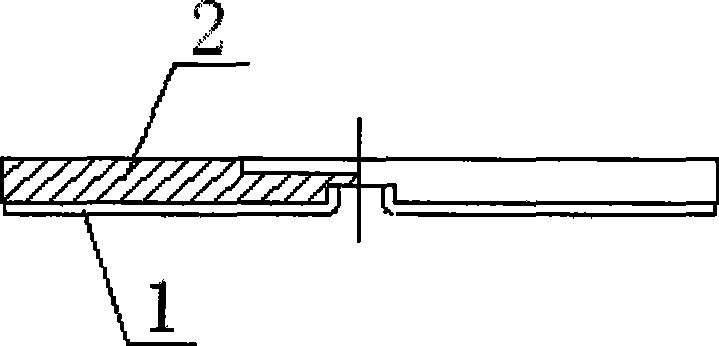

[0033] see figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 , Figure 6 , Figure 7 , the welding method of the mirror thin plate in the bridge bearing sliding plate assembly of the present invention, comprises the following steps:

[0034] A. Cutting

[0035] The mirror thin plate 1 for the sliding plate assembly of the multi-directional support is obtained by shearing and blanking with a shearing machine, or after shearing and blanking with a shearing machine, the side corresponding to the concave groove 4 on the sliding plate 2 is pressed into a right-angled shape to obtain Mirror sheet 1 for lateral and longitudinal support slide plate assembly. Use a file to file and deburr the periphery of the mirror sheet 1, and then finely grind the periphery of the mirror sheet 1 with a whetstone;

[0036] B. Marking and...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com