Extinguishment product using clear gas as sponging agent as well as production method and fire-extinguishing system

A technology of clean gas and production method, applied in fire prevention equipment, fire rescue and other directions, can solve problems such as inability to extinguish chemical substances, inability to extinguish fires, and difficult to extinguish combustion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0019] Embodiment 1: A fire extinguishing product using clean gas as a foaming agent is composed of a clean gas fire extinguishing agent and a foam fire extinguishing agent. The gas foam fire extinguishing product in the gas foam fire extinguishing product is a clean gas, and the clean gas Extinguishing agent refers to trifluoroiodomethane, perfluoropropane, perfluorobutane, perfluoroethane, dichlorodifluoroethane, chlorodifluoromethane, 1 chlorotetrafluoroethane, pentafluoroethane, heptafluoropropane , trifluoromethane, hexafluoropropane, argon, nitrogen, carbon dioxide, argon nitrogen and carbon dioxide to form a mixed gas, and the foam fire extinguishing agent refers to protein foam, fluoroprotein foam, anti-solubilizing fluoroprotein foam, film-forming fluoroprotein foam, Aqueous film-forming foam, solvent-resistant aqueous film-forming foam, synthetic foam. The making of above-mentioned product is prior art, does not describe here.

Embodiment 2

[0020] Embodiment 2: use clean gas as the manufacture method of the fire extinguishing product of blowing agent, it comprises clean gas fire extinguishing agent and foam fire extinguishing agent, uses clean gas fire extinguishing agent as the foaming medium of foam fire extinguishing agent, described clean gas fire extinguishing agent Refers to trifluoroiodomethane, perfluoropropane, perfluorobutane, perfluoroethane, dichlorodifluoroethane, chlorodifluoromethane, chlorotetrafluoroethane, pentafluoroethane, heptafluoropropane, three Fluoromethane, hexafluoropropane, argon, nitrogen, carbon dioxide, argon, nitrogen and carbon dioxide form a mixed gas, and the foam fire extinguishing agent refers to protein foam, fluoroprotein foam, anti-alcohol fluoroprotein foam, film-forming fluoroprotein foam, aqueous Film foam, solvent-resistant aqueous film-forming foam, synthetic foam. .

Embodiment 3

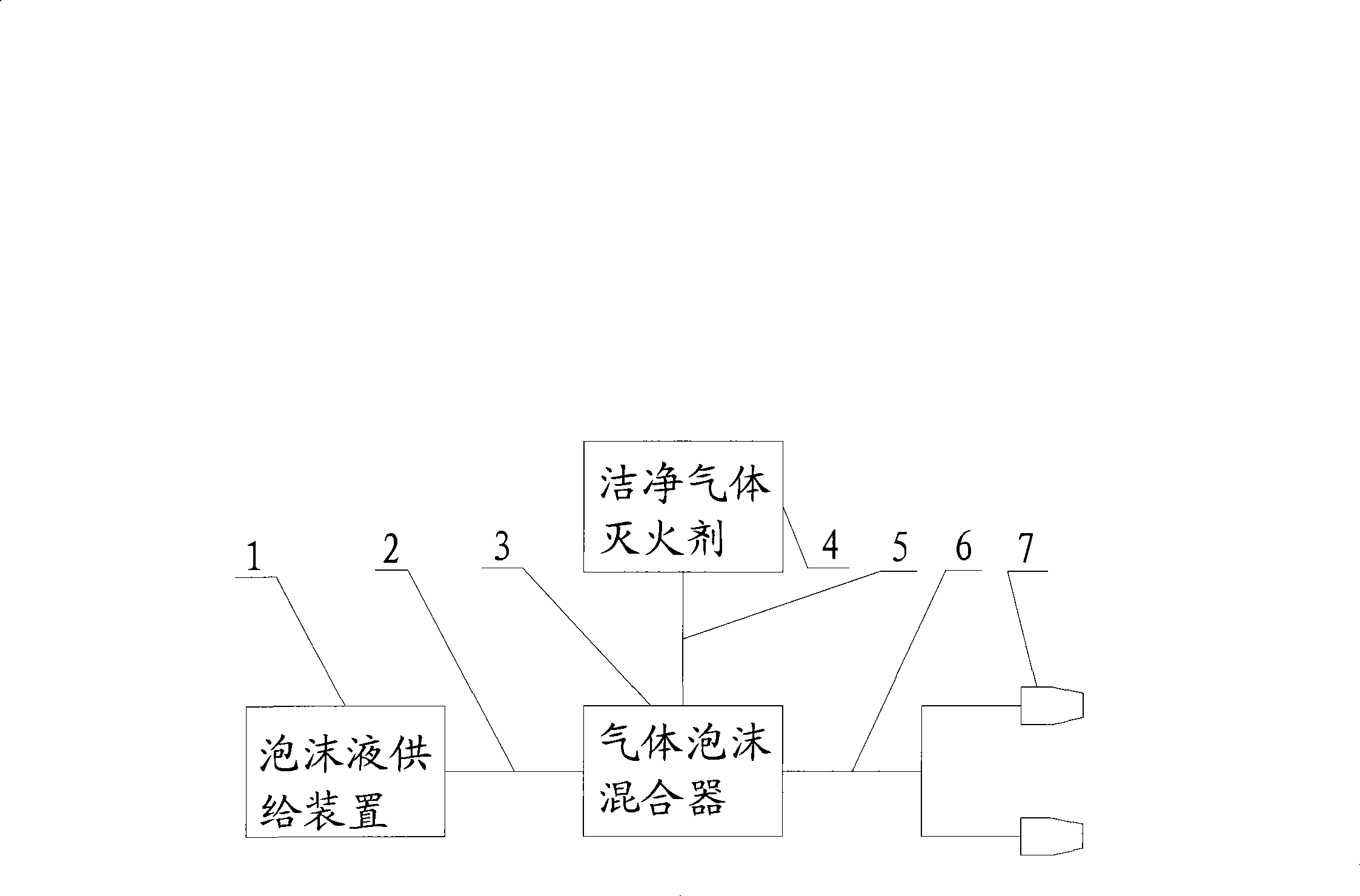

[0021] Embodiment 3: with reference to attached figure 1 On the basis of Embodiment 1 or 2, or Embodiment 1 and 2, the anaerobic foam double fire extinguishing system, the foam liquid supply device 1 and the gas foam mixer 3 are connected by pipeline 2, and the clean gas fire extinguishing agent 4 is connected by pipeline 5 It communicates with the gas foam mixer 3 , and the outlet of the gas foam mixer 3 communicates with the foam generator 7 through the pipeline 6 . Described gas foam mixer 3 is prior art, as the fire extinguishing agent that produces fire extinguishing foam with the method of mechanical or chemical reaction, so do not describe here. Workflow: Mix gaseous fire extinguishing agent on the foam liquid supply facility according to the design ratio, and ensure that the working pressure of the system is greater than the saturated vapor pressure of the gas fire extinguishing agent itself, so that the gas fire extinguishing agent and foam liquid also flow in liquid ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com