Plasma flat light source structure and LCD device

A technology for liquid crystal display devices and planar light sources, which is applied in gas plasma lamps, optics, nonlinear optics, etc., can solve the problems of high cost of filter material layers and rising manufacturing costs of plasma planar light source structures, and achieve improved color purity and excellent The effect of display quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

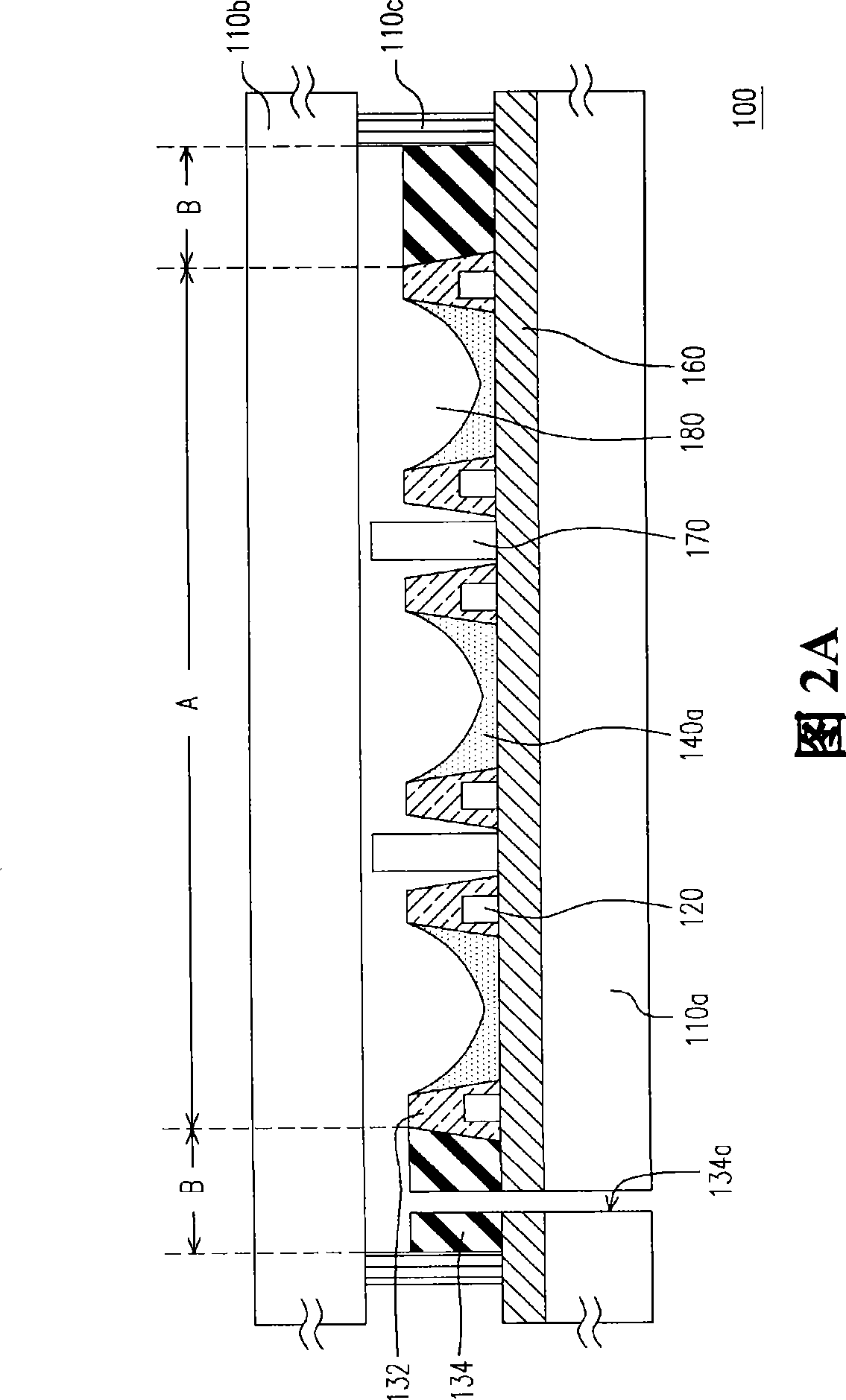

[0069] Fig. 2A is a schematic structural diagram of the plasma planar light source structure of the first embodiment. 2A, the plasma planar light source structure 100 includes a first substrate 110a, a plurality of electrode lines 120, a plurality of dielectric patterns 132, a dielectric layer 134, a first fluorescent material layer 140a, a second substrate 110b and a sealant 110c. The installation positions and materials of each component will be described below.

[0070] The first substrate 110a has a light emitting area A and a peripheral area B surrounding the light emitting area A. As shown in FIG. The electrode lines 120 are disposed on the first substrate 110a and extend from the peripheral area B to the light emitting area A. As shown in FIG. The dielectric patterns 132 are disposed on the first substrate 110a, and each dielectric pattern 132 covers the electrode lines 120 therein. The dielectric layer 134 covers the peripheral area B of the first substrate 110a, whe...

no. 2 example

[0080] Fig. 3A is a schematic structural view of the plasma planar light source structure of the second embodiment, Figure 3B It is a top view of the partition wall of the plasma planar light source structure in FIG. 3A . Please refer to FIG. 3A , the plasma planar light source structure 200 is similar to the above-mentioned plasma planar light source structure 100 , the difference is that: the plasma planar light source structure 200 also includes a second fluorescent material layer 140 b and a partition wall 210 . The second fluorescent material layer 140b is disposed on the second substrate 110b, and includes red, green and blue fluorescent materials, for example. When ultraviolet rays irradiate the second fluorescent material layer 140b, the red, green and blue fluorescent materials in the second fluorescent material layer 140b will also emit red, green and blue light, so as to mix colors to form white light. The partition wall 210 is disposed on the second substrate 110b...

no. 3 example

[0084] Fig. 4A is a schematic structural diagram of the plasma planar light source structure of the third embodiment, Figure 4B It is a top view of the first partition wall of the plasma planar light source structure in FIG. 4A . Please refer to Figure 4A together with Figure 4B , the plasma planar light source structure 300 is similar to the plasma planar light source structure 100 of the first embodiment, the difference is that: the plasma planar light source structure 300 does not have the dielectric layer 134 , but has the first partition wall 312 . The first partition wall 312 is disposed on the peripheral region B of the first substrate 110a, and the first substrate 110a inside the first partition wall 312 has a through hole 320 therein. The first partition wall 312 is fabricated on the first substrate 110a by, for example, screen printing technology or other suitable methods. In addition, the first partition wall 312 has a first notch 312a, and the first notch 312a ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com