Apparatus and method for detecting impurity in milk

A technology of testing equipment and testing methods, applied in the direction of testing food, material testing products, testing dairy products, etc., can solve difficult large-scale, industrialized, fully automatic applications, does not provide fast, assembly line operation equipment, does not provide a judgment Adulteration standards and other issues, to achieve the effect of convenient and fast operation, reduced inspection time, and obvious phenomena

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

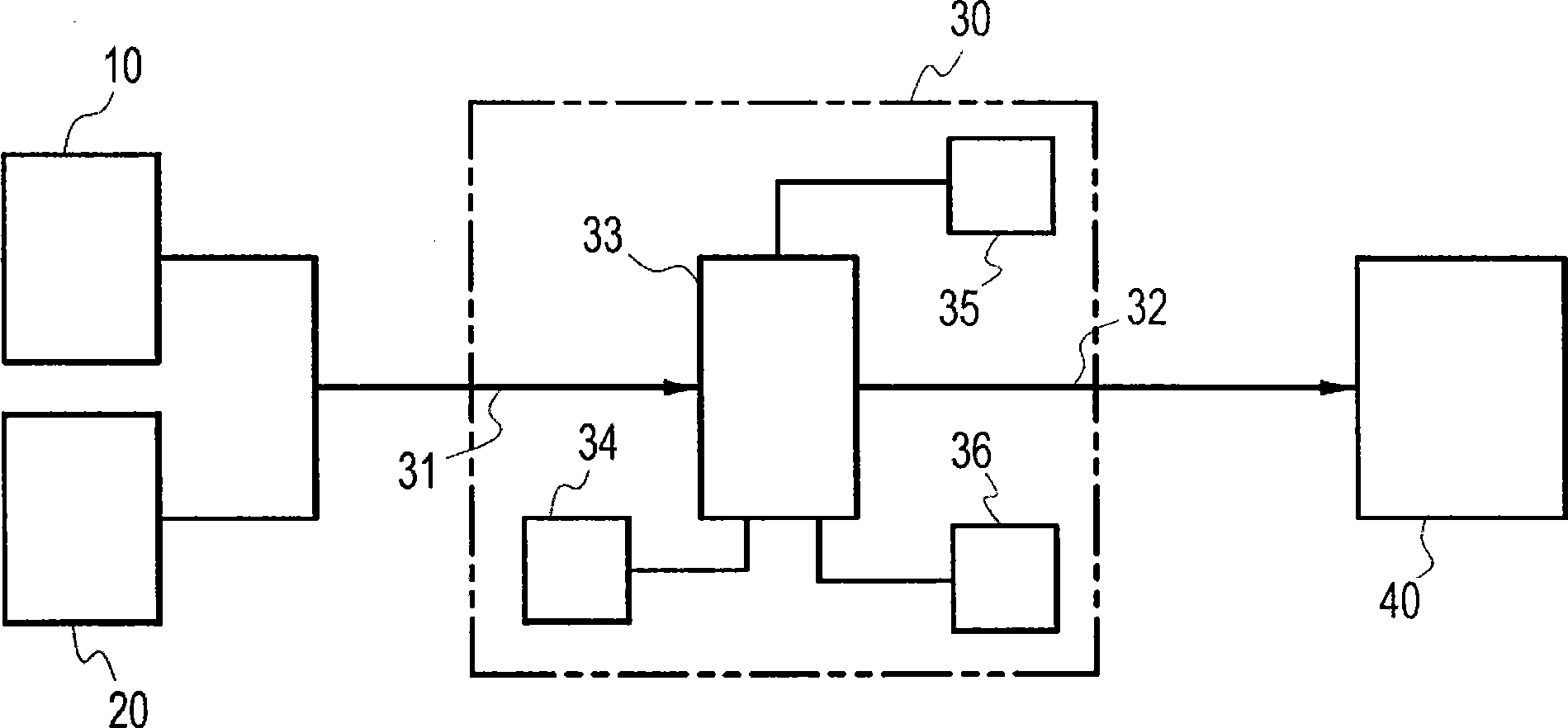

[0027] The invention provides a detection device for impurities in milk, such as figure 1 As shown, the detection device includes at least one conductivity detection unit 10 , at least one temperature detection unit 20 , at least one data processing unit 30 and at least one display unit 40 . Wherein, the conductivity detection unit 10 and the temperature detection unit 20 can adopt the same detection equipment as described in the prior art literature described in the background technology section, or other commonly used electronic sensors that can detect conductivity and temperature, specifically, conductivity The detection unit 10 and the temperature detection unit 20 can be set to simultaneously measure a conductivity value K and a temperature value T of the milk (raw milk or fresh milk) to be tested.

[0028] The detection device for impurities in milk according to the present invention is a detection device that can be applied to an assembly line. Therefore, those skilled ...

Embodiment 2

[0053] This embodiment provides a method for detecting impurities in milk using the above-mentioned impurity detection equipment in milk, the method comprising the following steps:

[0054] The standard conductivity value K of the milk to be detected at different temperatures T is stored in the data processing unit 30 S ;

[0055] Store a preset deviation reference value K in the data processing unit 30 P ;

[0056] A conductivity value K and a temperature value T of the milk are simultaneously detected by the conductivity detection unit 10 and the temperature detection unit 20;

[0057] The measured conductivity value K under the temperature value T is compared with the standard conductivity value K S Compare to obtain a deviation value K R , when the deviation value K R Greater than the above deviation from the reference value K P , the data processing unit 30 sends a first signal to the display unit 40; when the deviation value K R Less than the above deviation from ...

Embodiment 3

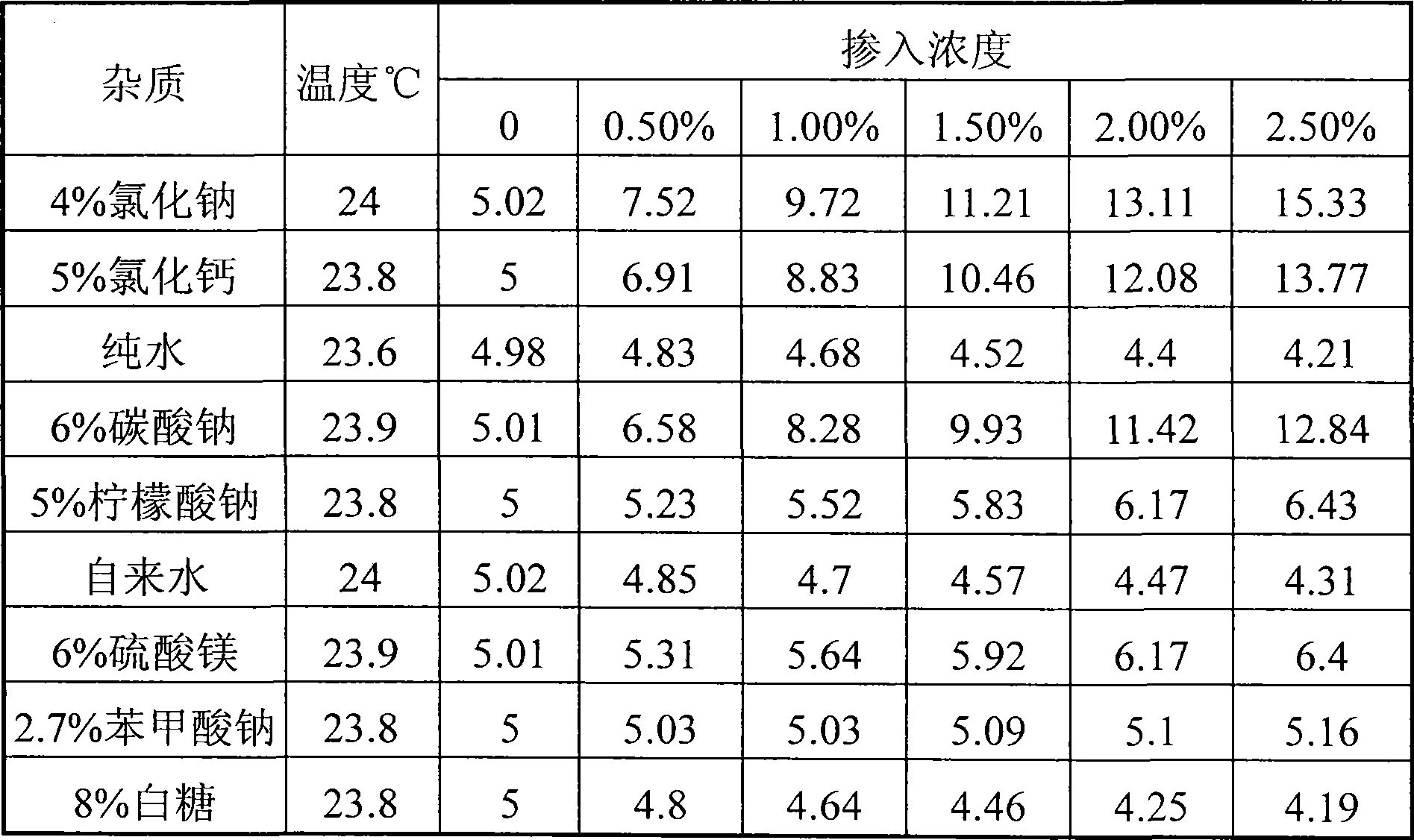

[0068] This example gives a verification example of detecting impurities in milk using the equipment for detecting impurities in milk in Example 1 of the present invention.

[0069] Firstly, the milk module is selected by operating the selection module 36 displayed on the display unit 40 on its display screen.

[0070] Then operate and select on the display screen to set the deviation reference value K of the corresponding milk P 0.05ms / cm.

[0071] Take not less than 50 mL of milk to be tested in a beaker, measure the sample with the milk impurity detection device of the present invention, put the conductivity detection unit 10 and the temperature detection unit 20 into the sample to be tested at the same time, shake gently, make the milk and the conductivity After the electrodes and the temperature probes of the rate detection unit 10 and the temperature detection unit 20 are in full contact, take readings and record the results.

[0072] Take 8 test milk samples artificia...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com