Vacuum belt type drying units

A vacuum belt drying and unit technology, applied in the direction of dryers, drying, lighting and heating equipment, etc., can solve the problems of affecting the color of dry powder, poor water solubility, sticking, etc., and achieve the effect of stable and reliable drying quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

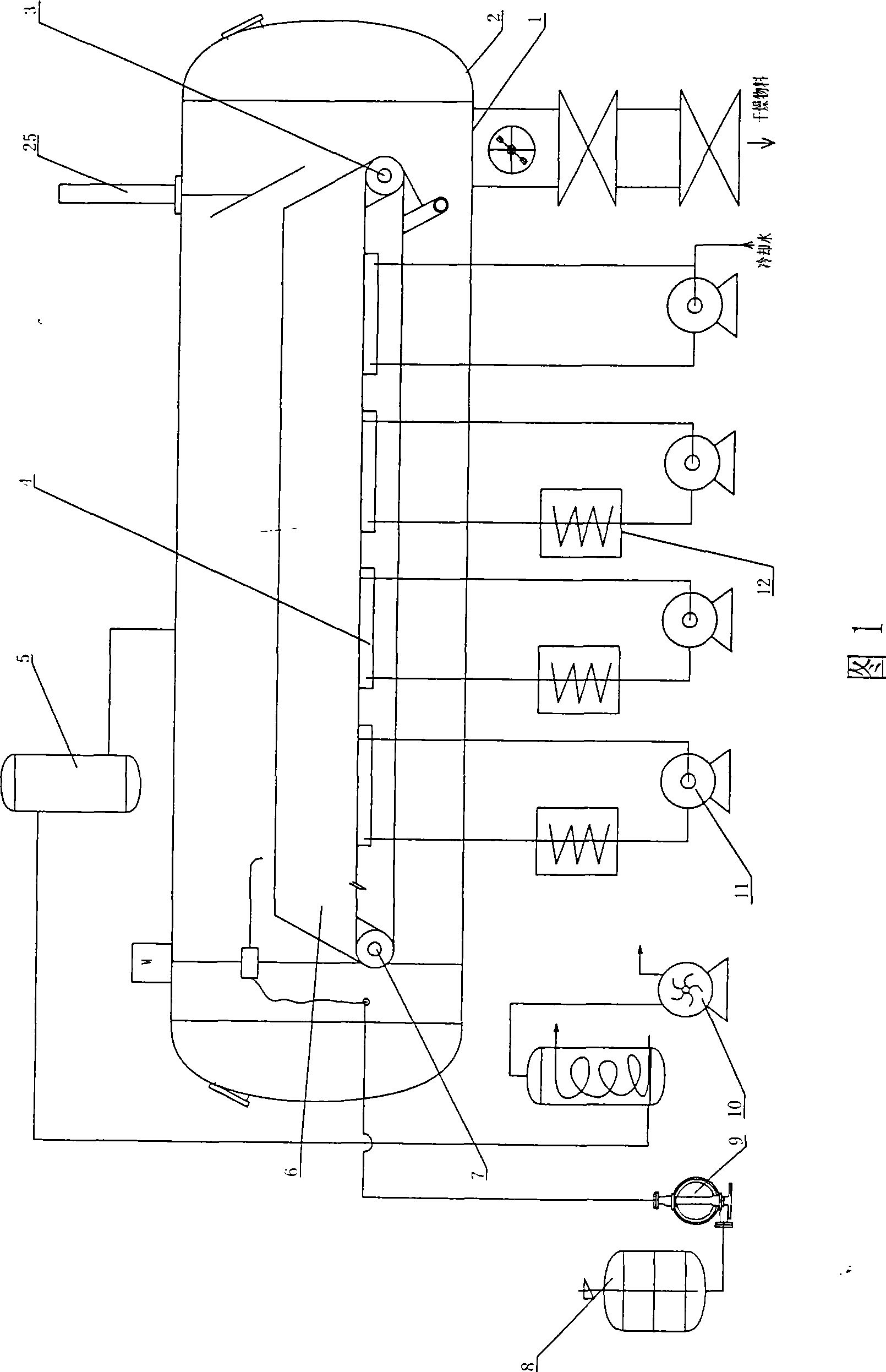

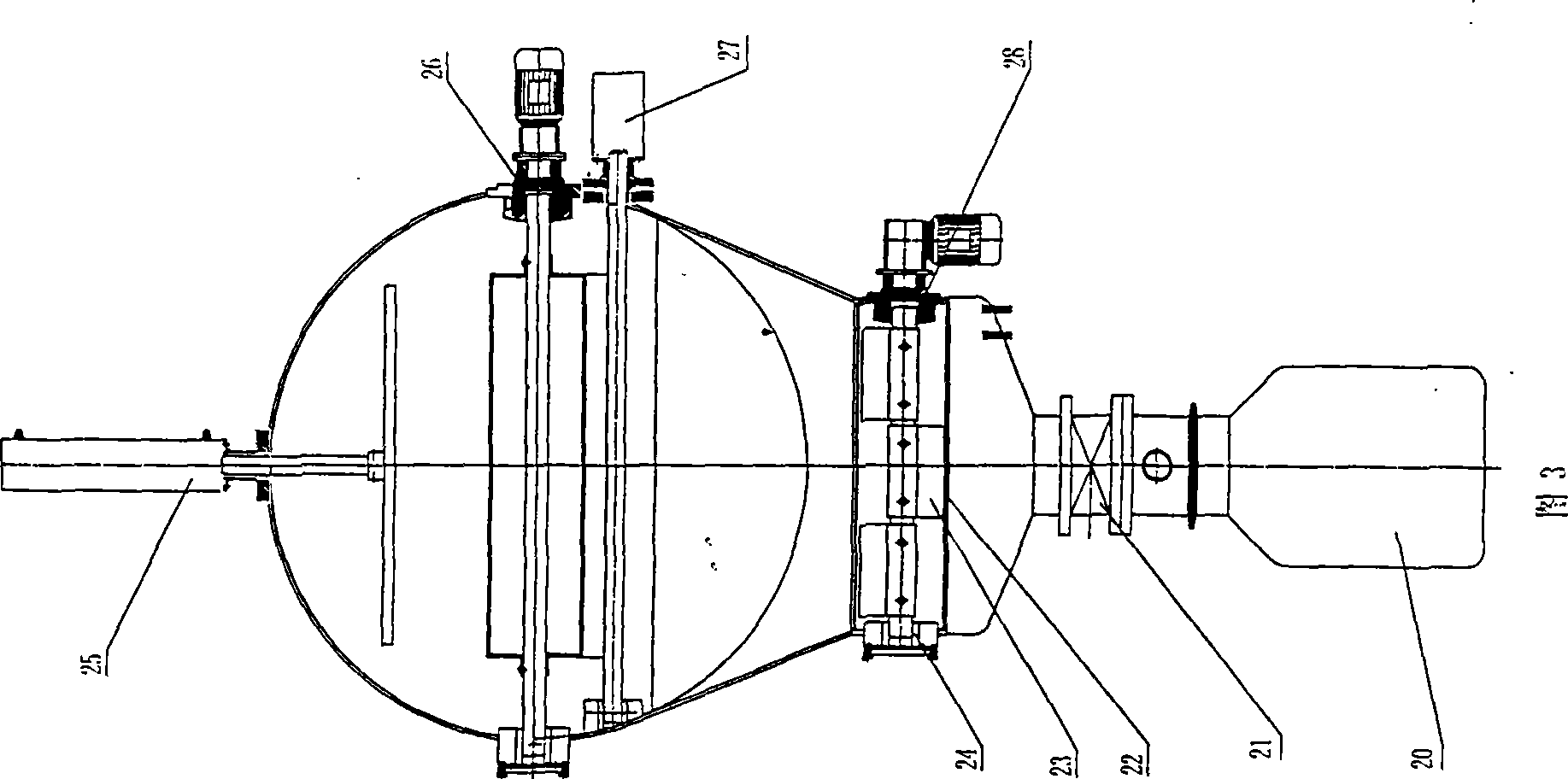

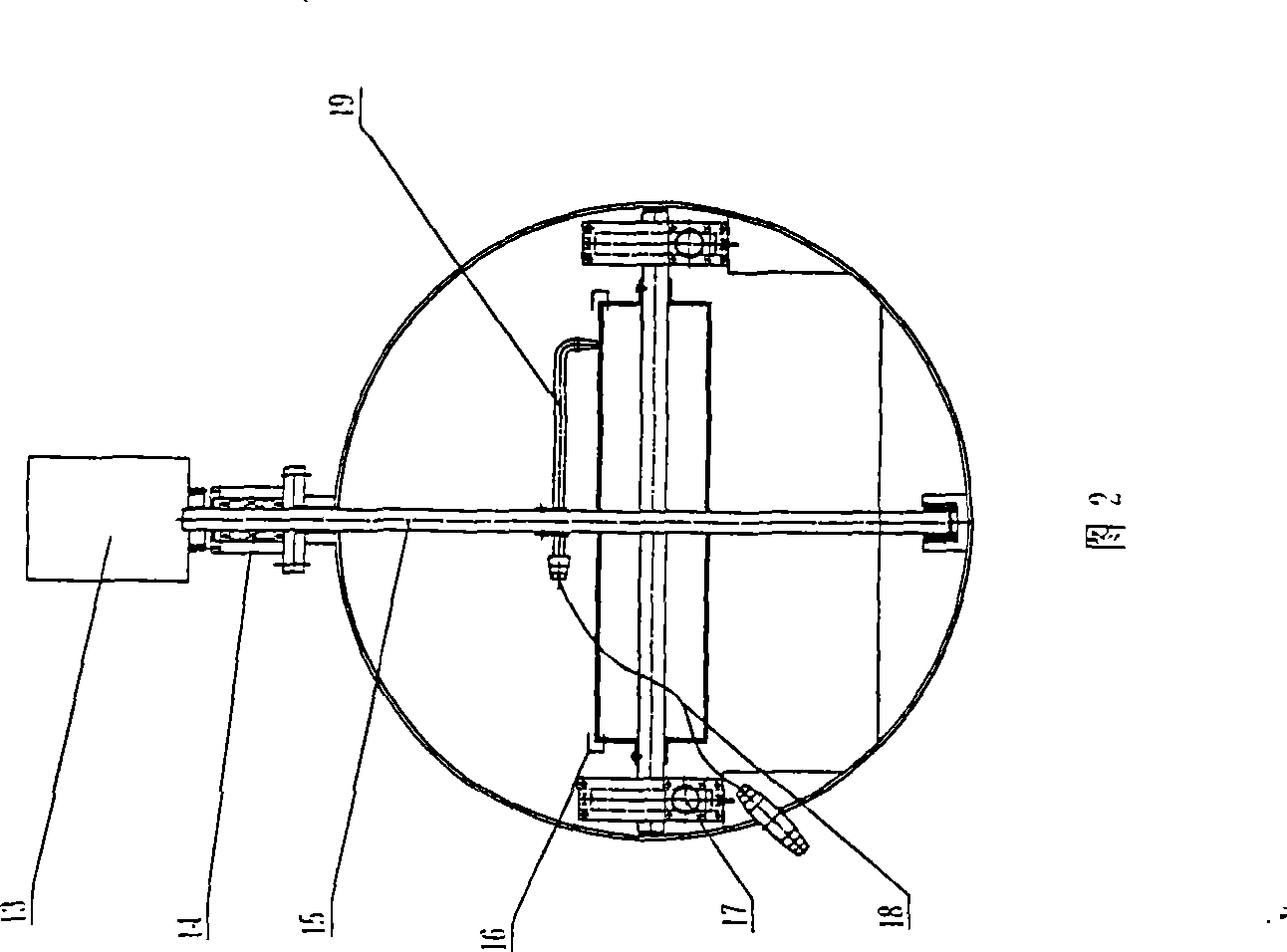

[0012] As shown in Fig. 1, Fig. 2 and Fig. 3, the vacuum belt drying unit provided in this embodiment includes a vacuum chamber 1, and a sealing head 2 is respectively arranged at the front and rear ends of the vacuum chamber 1. The vacuum chamber The body 1 is equipped with a material conveyor belt transmission mechanism, the upper end of the vacuum chamber 1 is connected with an adjustable vacuum system 10 connected to the condenser 5, the front end of the unit is equipped with a feeding mechanism and a material distribution mechanism, and the rear end of the unit is sequentially equipped with a cutting mechanism , shovel powder mechanism, crushing mechanism and material collector.

[0013] The material conveying belt conveying mechanism comprises at least one material conveying belt 6, the front and rear ends of the material conveying belt 6 are provided with a front conveying roller 7 and a rear conveying roller 3, and the polytetrafluoro material conveying belt 6 is laid o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com