Method for recycling polyvinyl chloride or polyvinylidene chloride plastic

A polyvinyl chloride and plastic technology, applied in plastic recycling, recycling technology, bulk chemical production, etc., can solve problems such as high energy consumption and solvent residue, and achieve the effects of low energy consumption, easy separation and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

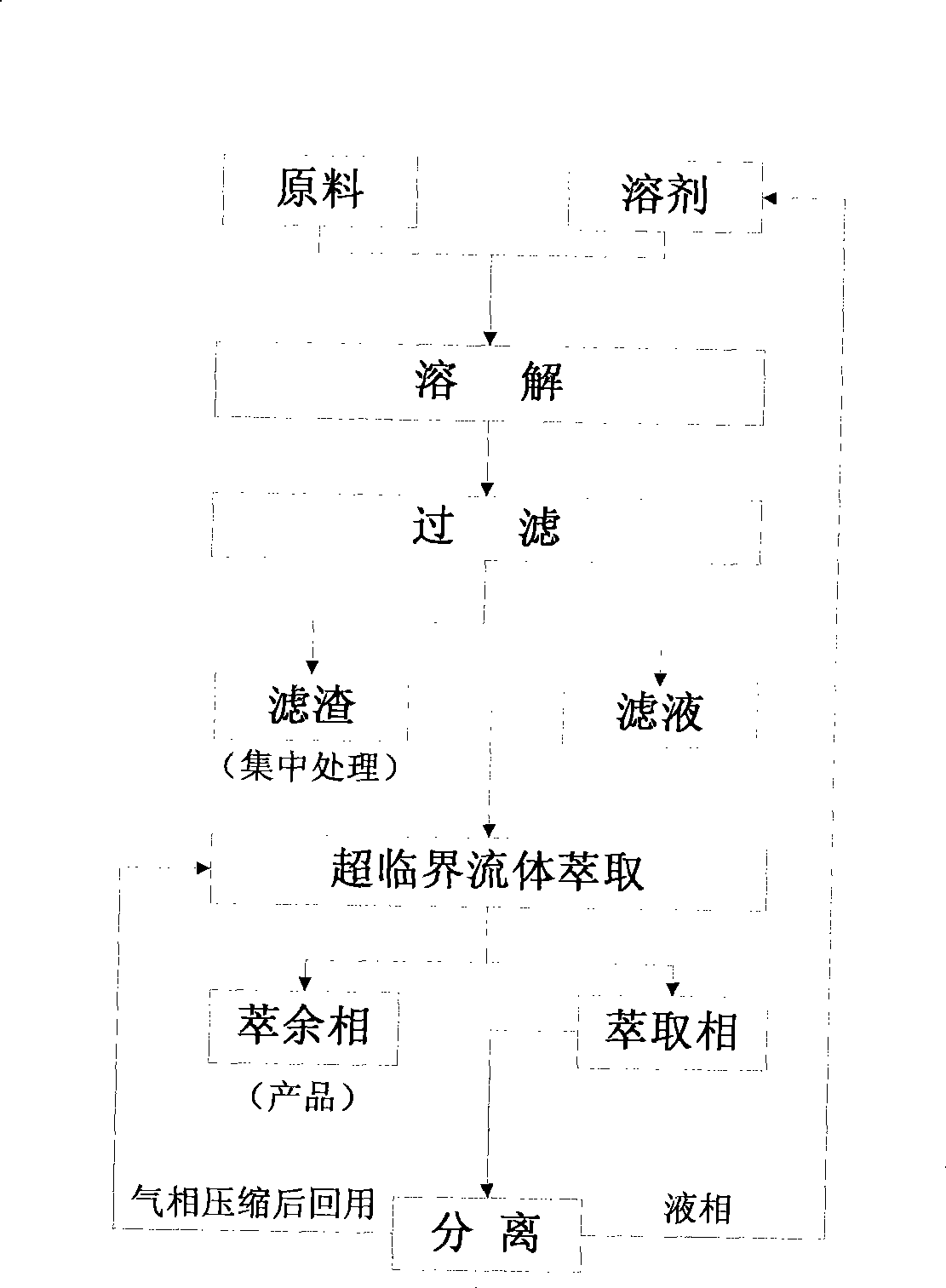

Image

Examples

Embodiment 1

[0029] 1. Prepare 50kg of a solution containing 80% methyl ethyl ketone and 20% n-hexane (mass ratio), pour it into a stirred tank, and heat it to 110°C.

[0030] 2. Under the condition of pressure of 0.3Mpa and temperature of 110℃, add 5kg of PVC to make it dissolve within 10 minutes.

[0031] 3. Keep the temperature of the solution not lower than 75°C, filter to remove insoluble matter, and send the filtrate to the precipitation reactor.

[0032] 4. Use continuous operation mode for supercritical fluid extraction. The filtrate is sprayed down from the top of the reactor into the reactor through the nozzle, supercritical carbon dioxide is introduced from the bottom and then contacts the filtrate countercurrently, the solvent is quickly extracted and the entrained solvent leaves the reactor from the top, and solid PVC particles are enriched at the bottom of the reactor . The extraction process lasted 20 minutes. After the extraction is finished, continue to pass through sup...

Embodiment 2

[0036] 1. Prepare 100 kg of a solution comprising 85% methyl ethyl ketone and 15% n-hexane (mass ratio), pour it into a stirred tank, and heat it to 115° C.

[0037] 2. Under the conditions of pressure 10Mpa and temperature 115℃, add 10kg PVC to dissolve within 15 minutes.

[0038] 3. Keep the temperature of the solution not lower than 75°C, filter to remove insoluble matter, and send the filtrate to the precipitation reactor.

[0039] 4. Use batch operation mode for supercritical fluid extraction. All the filtrate is poured into the precipitation reactor, supercritical methane is introduced from the bottom and then contacts with the filtrate, the solvent is quickly extracted and the entrained solvent leaves the reactor from the top, and solid PVC particles are enriched at the bottom of the reactor. The extraction process lasted 40 minutes. After the extraction, continue to pass through supercritical methane to dry the organic solvent remaining on the deposited particles. T...

Embodiment 3

[0043] 1. Pour 10kg of tetrahydrofuran solution into a stirred tank and heat to 100°C.

[0044] 2. Under the conditions of pressure 0.5Mpa and temperature 100℃, add 1.5kg PVC to dissolve within 10 minutes.

[0045] 3. Keep the temperature of the solution not lower than 75°C, filter to remove insoluble matter, and send the filtrate to the precipitation reactor.

[0046] 4. Use batch operation mode for supercritical fluid extraction. All the filtrate is poured into the precipitation reactor, supercritical ethylene is introduced from the top and then contacts the filtrate, the solvent is quickly extracted and the entrained solvent leaves the reactor from the top, and solid PVC particles are enriched at the bottom of the reactor. The extraction process lasted 30 minutes. After the extraction is completed, continue to pass through supercritical ethylene to dry the organic solvent remaining on the deposited particles. This drying process lasted 40 minutes.

[0047] 5. Ethylene f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com