Modified heat convertible resin coating urea

A resin-coated and coated urea technology, which is applied to urea compound fertilizers, nitrogen fertilizers, and fertilizer mixtures, can solve the problems of unfavorable promotion and application of thermosetting controlled-release fertilizers, slow resin degradation speed, and high prices of controlled-release fertilizers. Effects of soil security, yield increase and synergistic effects, broad market development prospects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

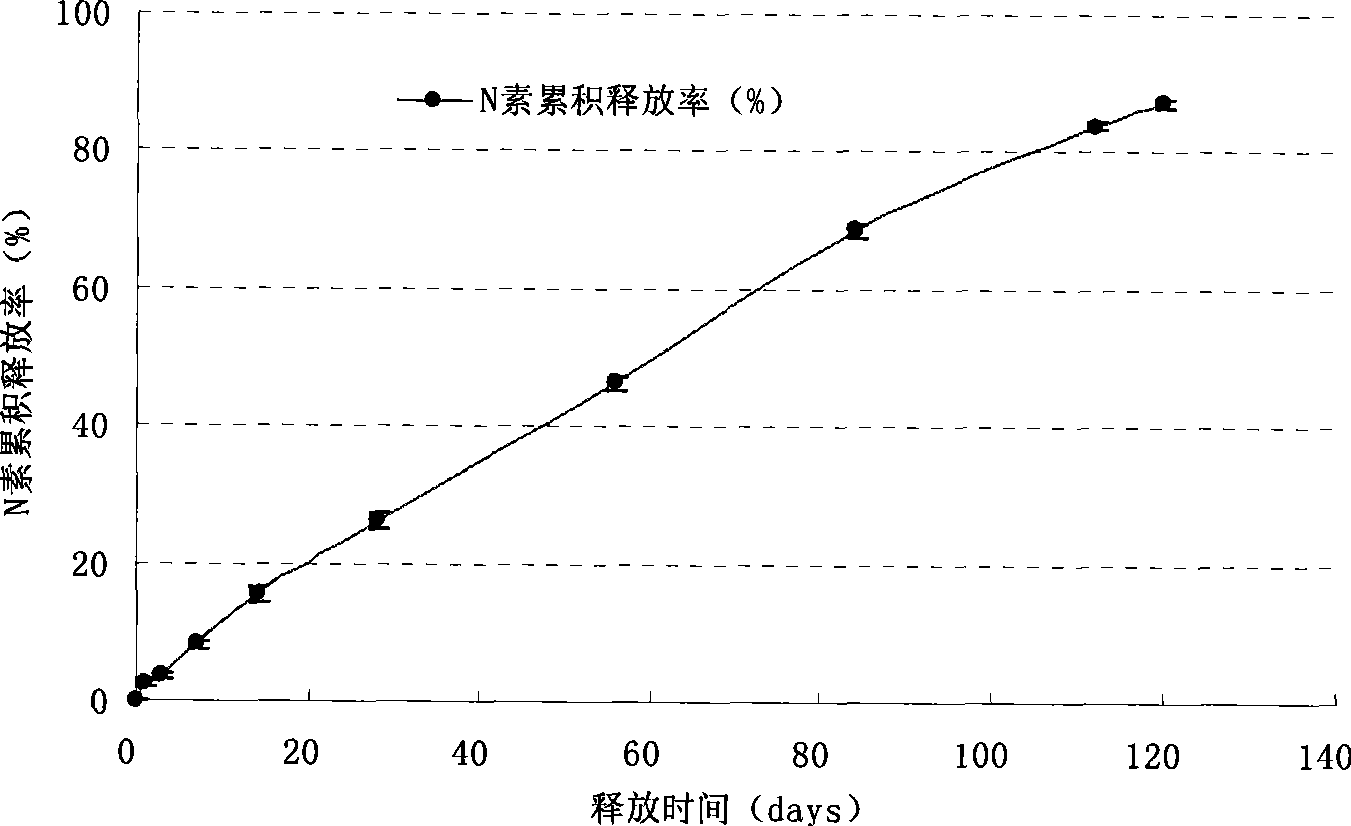

[0032] Example 1. Production of modified thermosetting resin-coated urea with a controlled release period of 2 months.

[0033] 1) Mix 18kg of thermosetting bisphenol A epoxy resin and 1.62kg of epoxy resin curing agent T-31 (manufactured and sold by Tianjin Yanhai Chemical Co., Ltd.), and add 5kg of coating modifier (including 3kg of sweet potato powder , rubber powder 1kg, bone powder 1kg), prepare the mixed solution;

[0034] 2) Preheat 1000kg of granular urea with a particle size range of 1.0-5.0mm to 75°C in a granulator;

[0035] 3) Add the mixed solution described in step 1) to the granular urea in the granulator, keep the temperature, and make the granulator continue to run for 5 minutes, that is, the coating is uniform and solidified to form a film; the coating rate is 2.5 %, modified thermosetting coated urea with a controlled release period of 2 months.

Embodiment 2

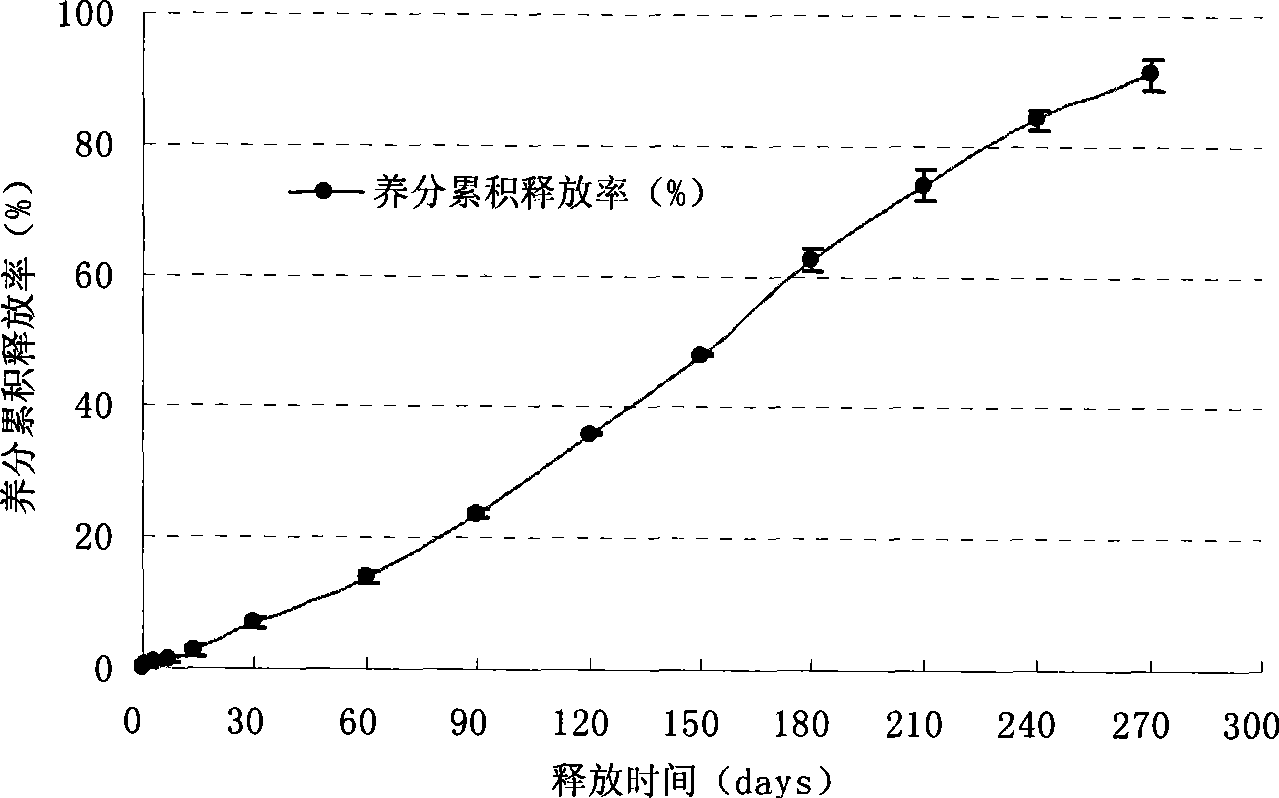

[0036] Example 2. Production of modified thermosetting resin-coated urea with a controlled release period of 10 months.

[0037] 1) Mix 21kg of thermosetting bisphenol A epoxy resin and 2.1kg of diethylenetriamine evenly, add 20kg of coating modifier (containing 16kg of mineral powder, 3kg of rubber powder, and 1kg of wheat flour), and prepare a mixed solution;

[0038] 2) Preheat 1000kg granular urea to 80°C in a granulator;

[0039] 3) Add the mixed solution described in step 1) to the granular urea in the granulator, keep the temperature, and keep the granulator running for 3 minutes, that is, the coating is uniform and solidified to form a film;

[0040] Repeat step 3) twice to obtain a modified thermosetting coated urea with a coating ratio of about 13% and a controlled release period of 10 months.

Embodiment 3

[0041] Example 3. Production of modified thermosetting resin-coated urea with a controlled release period of 12 months. .

[0042]1) Mix 23kg of thermosetting bisphenol A epoxy resin and 2.76kg of triethylenetetramine evenly, add 30kg of coating modifier (including 22kg of sweet potato powder, 3kg of zeolite powder, and 5kg of diatomaceous earth) to prepare a mixed solution ;

[0043] 2) Preheat 1000kg granular urea to 75°C in a granulator;

[0044] 3) Add the mixed solution described in step 1) to the granular urea in the granulator, keep the temperature, and make the granulator continue to run for 4 minutes, that is, evenly coat and solidify to form a film;

[0045] Repeat step 3) twice to obtain a modified thermosetting coated urea with a coating rate of about 17% and a controlled release period of 12 months.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com