Integrated heat radiator of fine antipriming pipe parallel flow for automobile

A technology that integrates heat dissipation and multi-hole tubes, which is applied in the power unit, the arrangement of the cooling combination of the power unit, and vehicle components, etc. It can solve the problems of the destruction of the atmospheric ozone layer of the vehicle refrigerant, the inability of the refrigerant and the tube to heat, and the inability of the refrigerant to dissipate heat. , to achieve the effect of large price advantage, low production cost, and improved installation and maintenance efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention will be described in further detail below in conjunction with the accompanying drawings, but the embodiments of the present invention are not limited thereto.

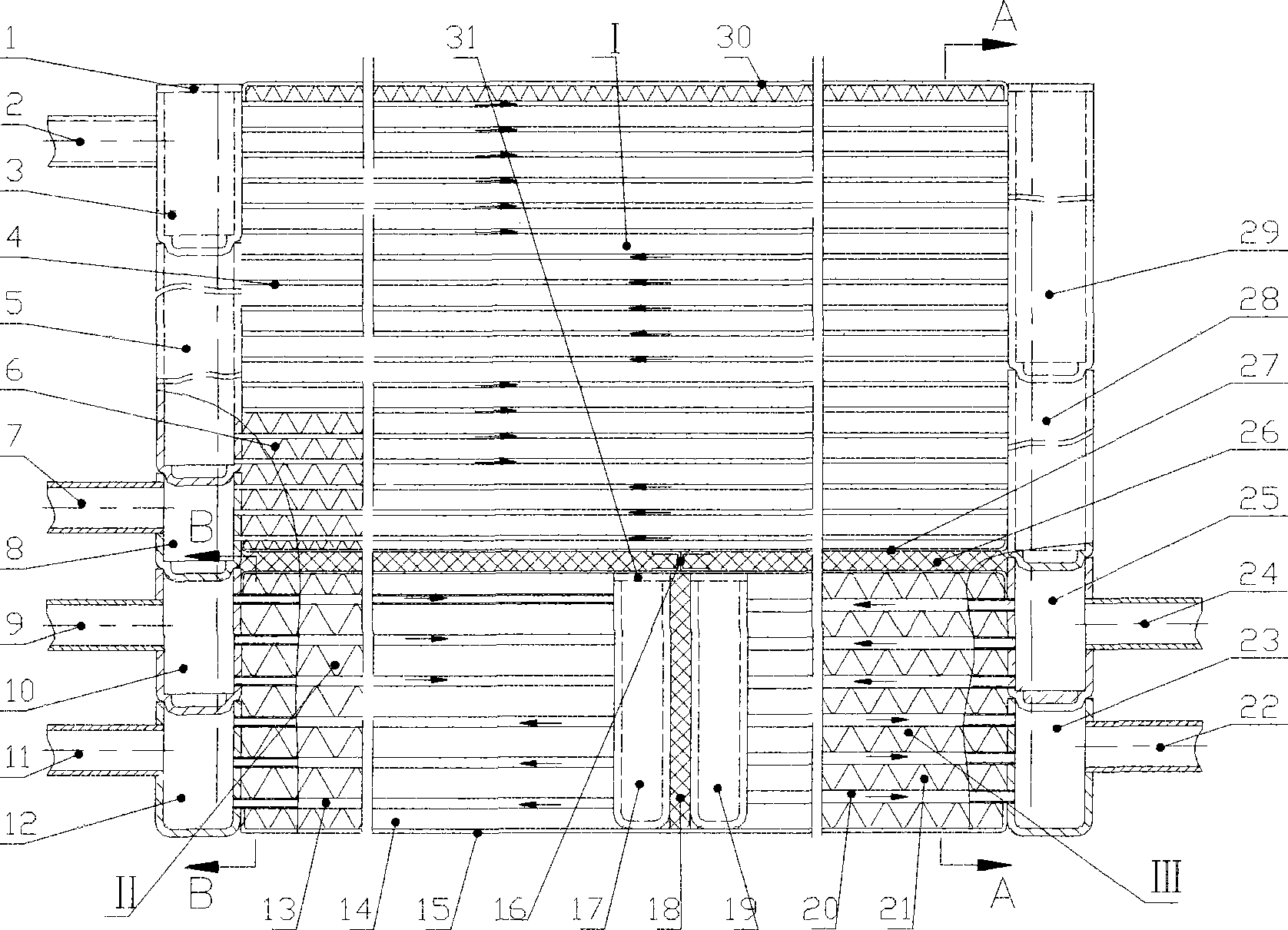

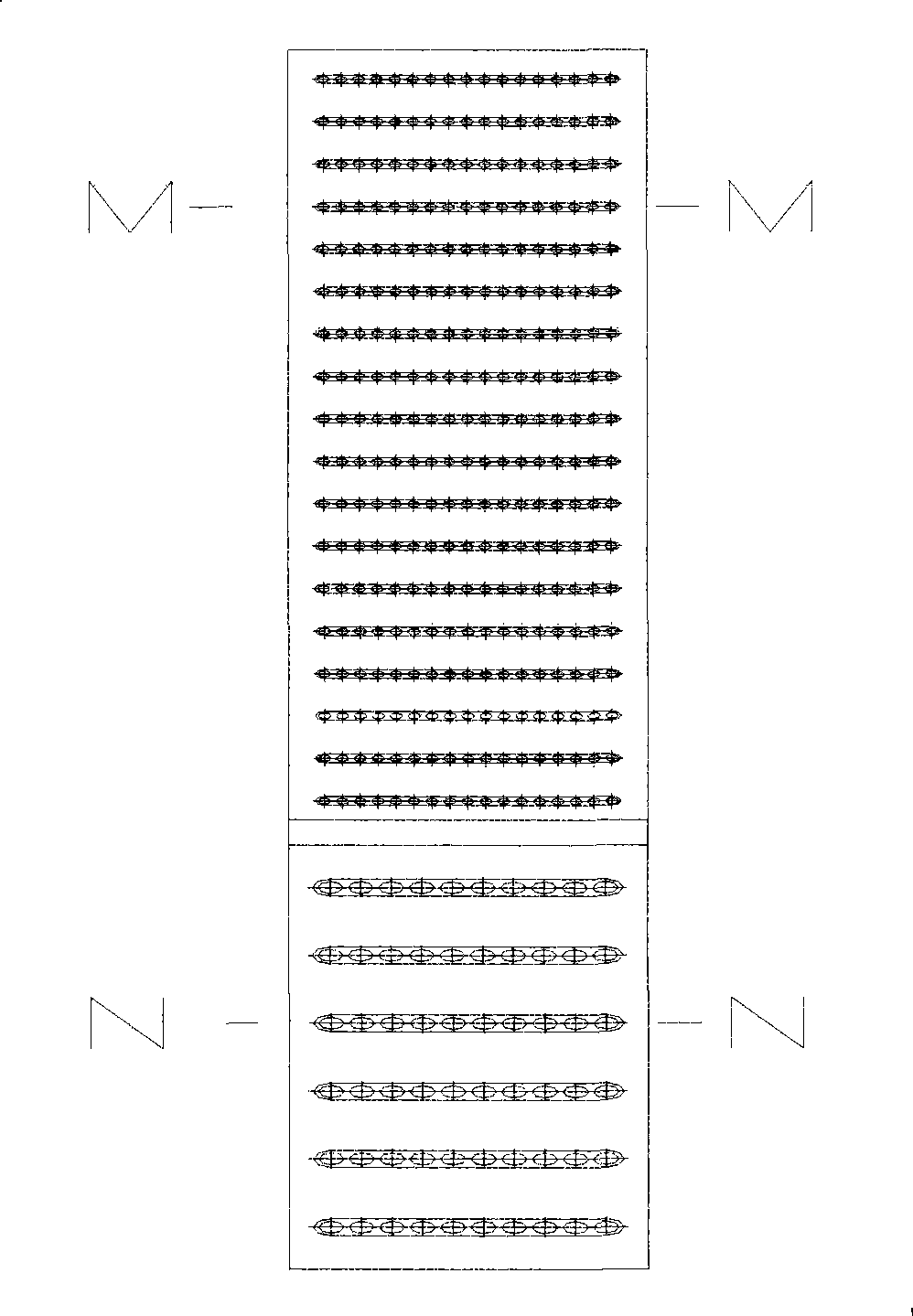

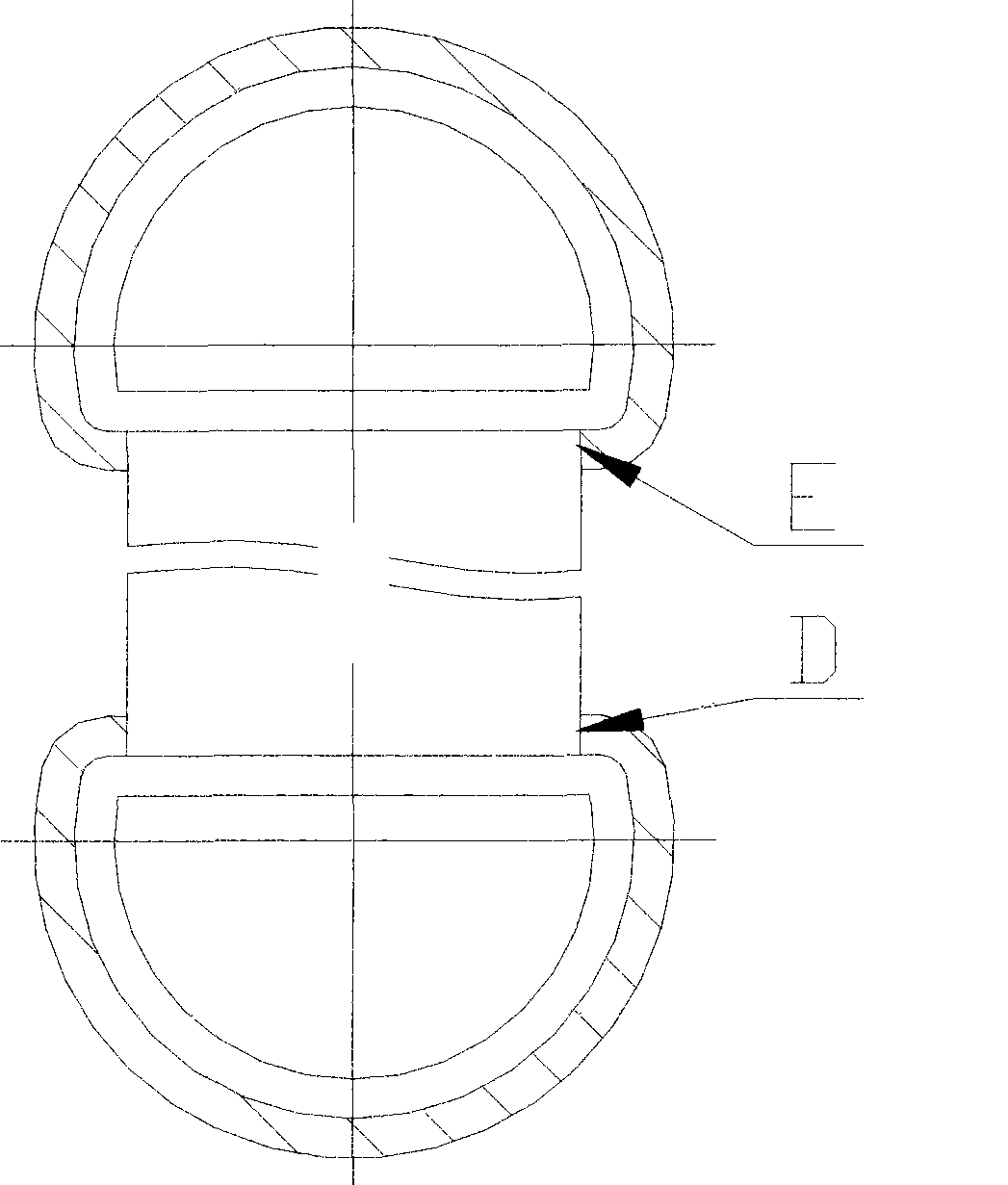

[0027] like figure 1 , 2 As shown in , 4, the micro-porous tube parallel flow integrated cooling device for automobiles includes an air-conditioning condenser I, a water tank radiator II and an engine oil cooler III, and the water tank radiator II and the engine oil cooler III are arranged side by side. The layers 18 are separated and are located at the lower end of the air-conditioning condenser I. The air-conditioning condenser I is separated from the water tank radiator II and the engine oil cooler III by the middle upper partition 27 and the middle lower partition 26. The middle upper partition 27 and the middle The lower partition 26 is fixed by the I-shaped bracket 16 .

[0028] The air conditioner condenser I is mainly composed of one of the header end covers 1, CO 2 (R744) (R744—...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Aperture | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com