Space block burr processor for transformer

A technology for transformers and processors, applied in metal processing equipment, milling machine equipment, manufacturing tools, etc., can solve the problems of affecting transformer test data, high labor intensity of operators, inconsistent product specifications, etc., to achieve uniform specifications and reduce operating skills. Requirements and labor intensity, the effect of high degree of automation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

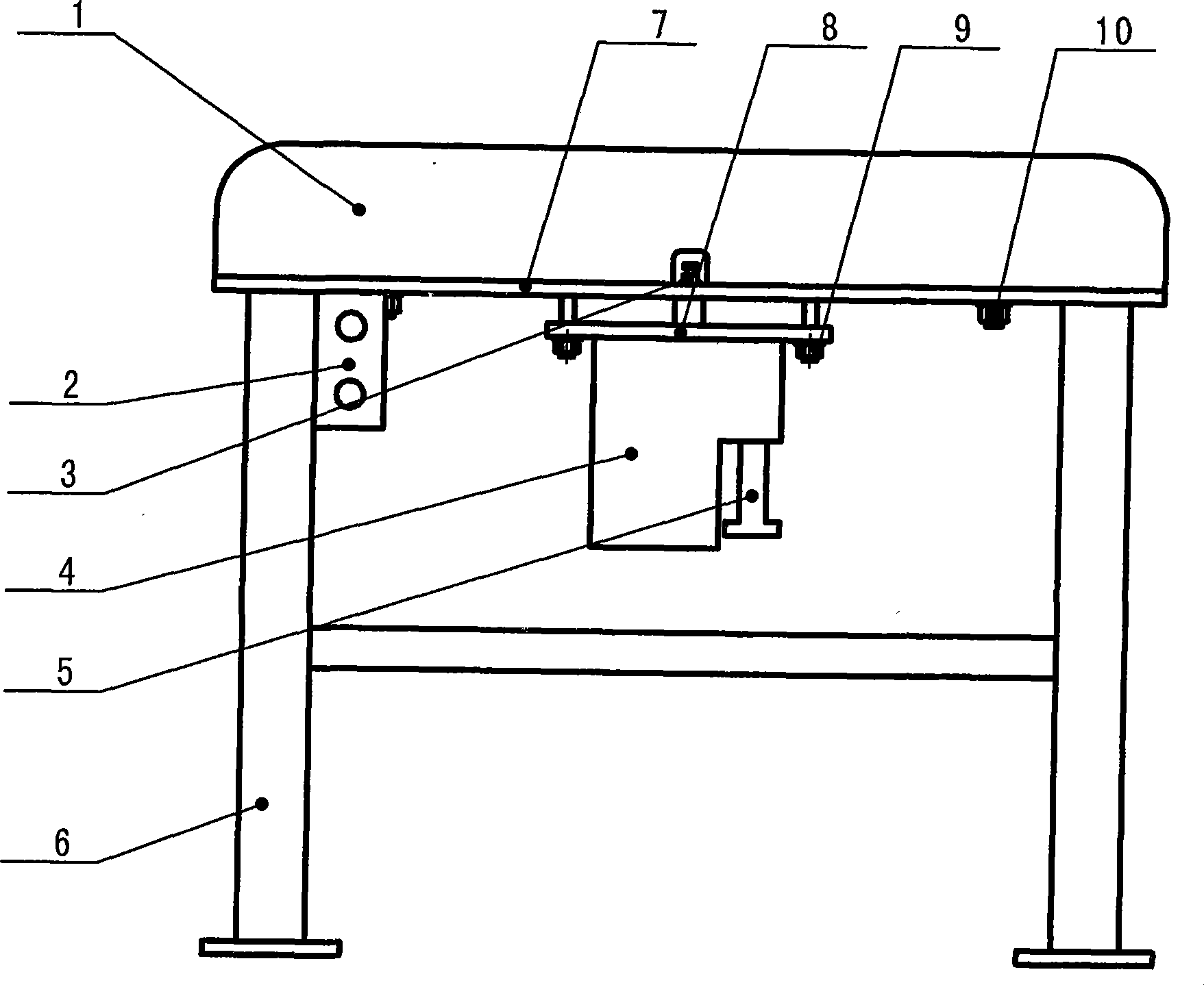

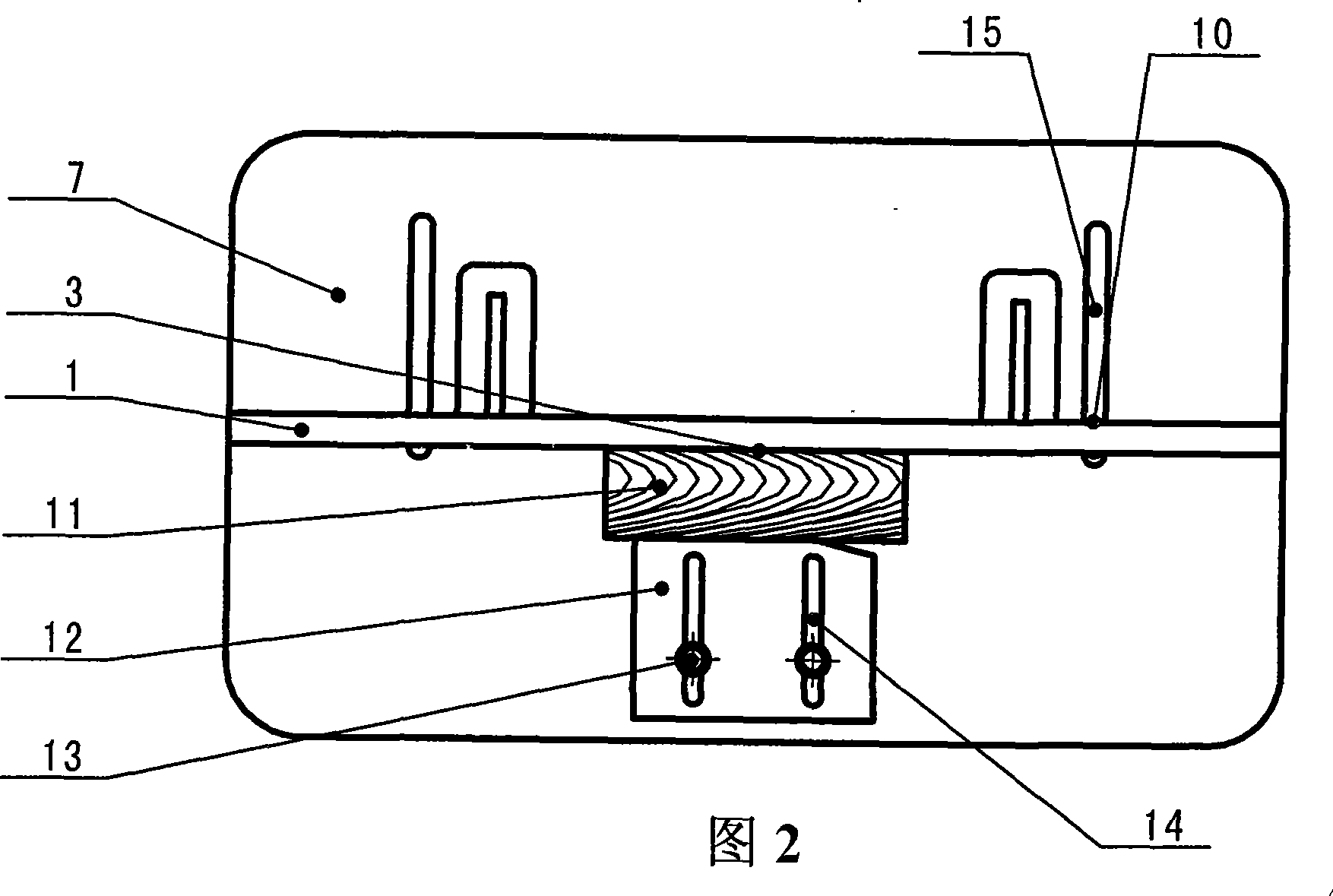

[0015] The present invention mainly consists of a bracket 6 with a workbench 7 and a control switch 2, placed on the workbench 7 with a baffle plate 1 with a fixing bolt 10, a limit plate 12, and a baffle adjustment groove 15, and placed on the lower part of the workbench 7 with a milling The motor 4 of knife 3 is placed on the limit plate 12 and constitutes such as limit plate adjustment groove 14 with limit bolt 13;

[0016] The present invention will be further described below in conjunction with the main process of pad burr treatment:

[0017] 1. The operator adjusts the up and down lifting handle 5 according to the drawing requirements of the spacer 11, so that the motor 4 and the milling cutter 3 move up and down on the workbench 7 to the size required by the drawing and then fix it; then fix the baffle 1 together with the fixing bolts on the back 10 Move back and forth in the baffle adjustment groove 15 until the size required by the drawings and tighten the fixing bolt...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com