Environment-friendly type quick salted egg bloating process and apparatus thereof

A production method and technology of a production device, which are applied in the field of environment-friendly rapid salted egg pickling production and its production device, can solve the problems of cumbersome procedures, high labor intensity, low utilization rate of material and liquid, etc., so as to avoid environmental pollution and shorten the pickling time. The effect of reducing the production cycle and reducing labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

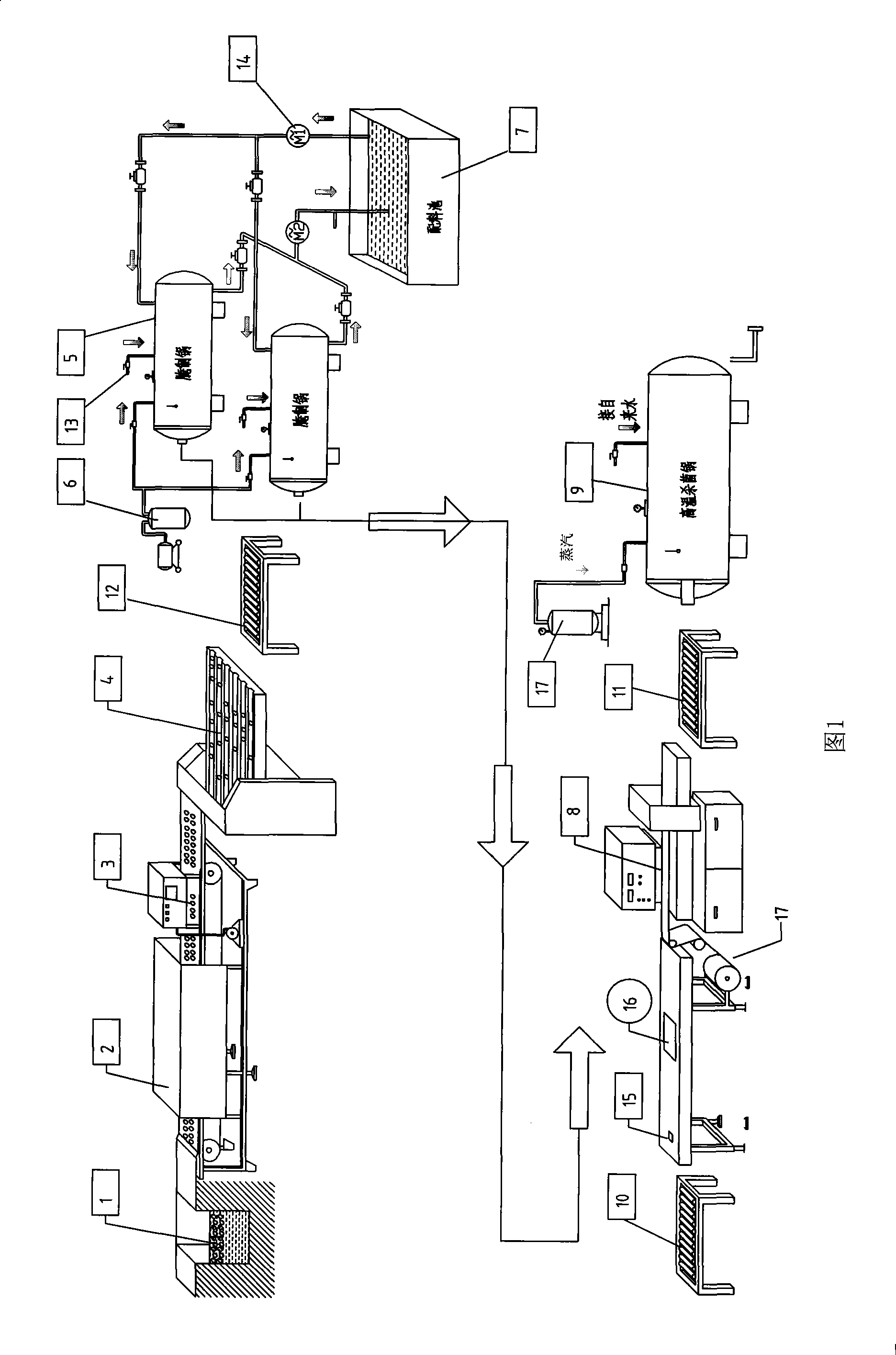

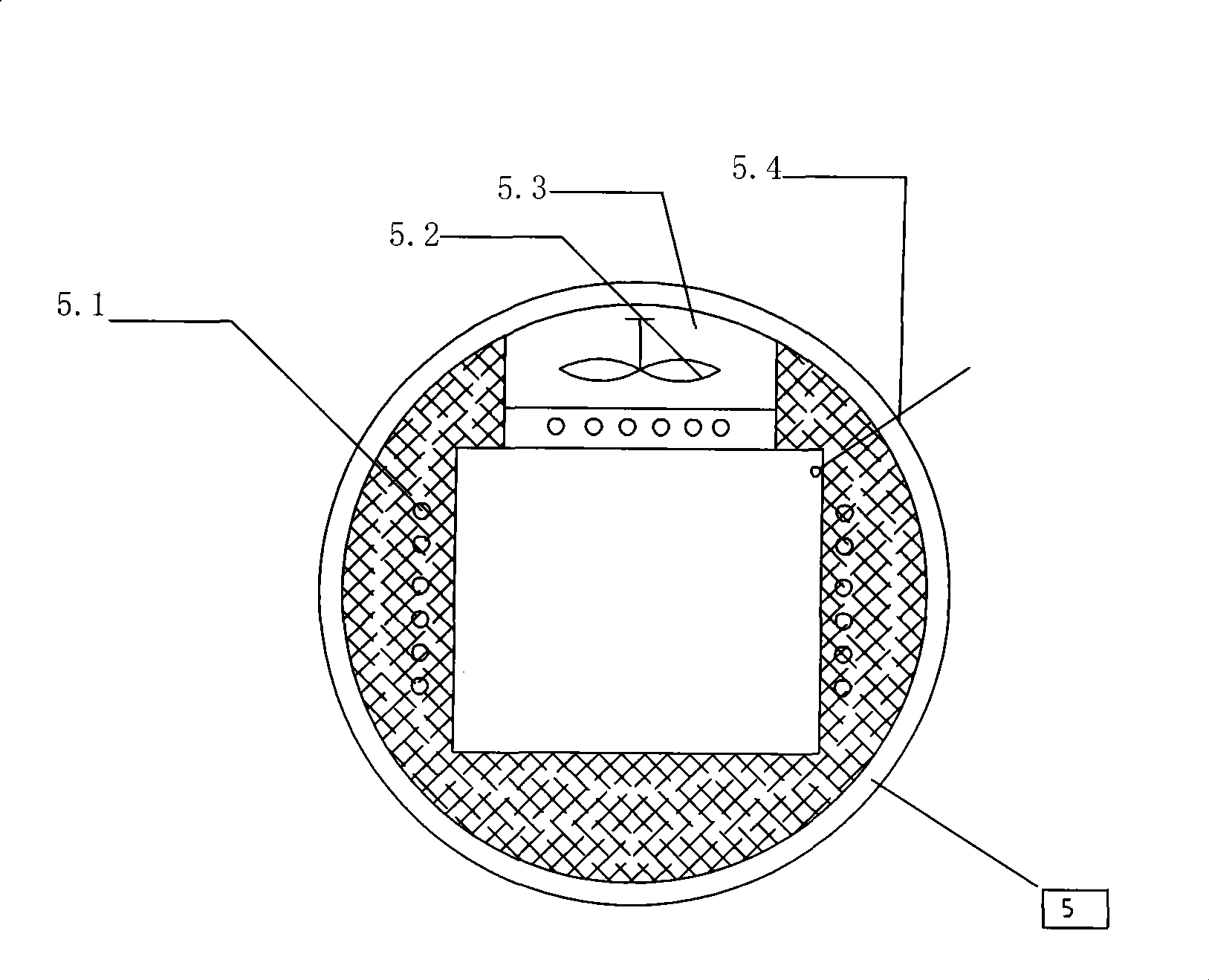

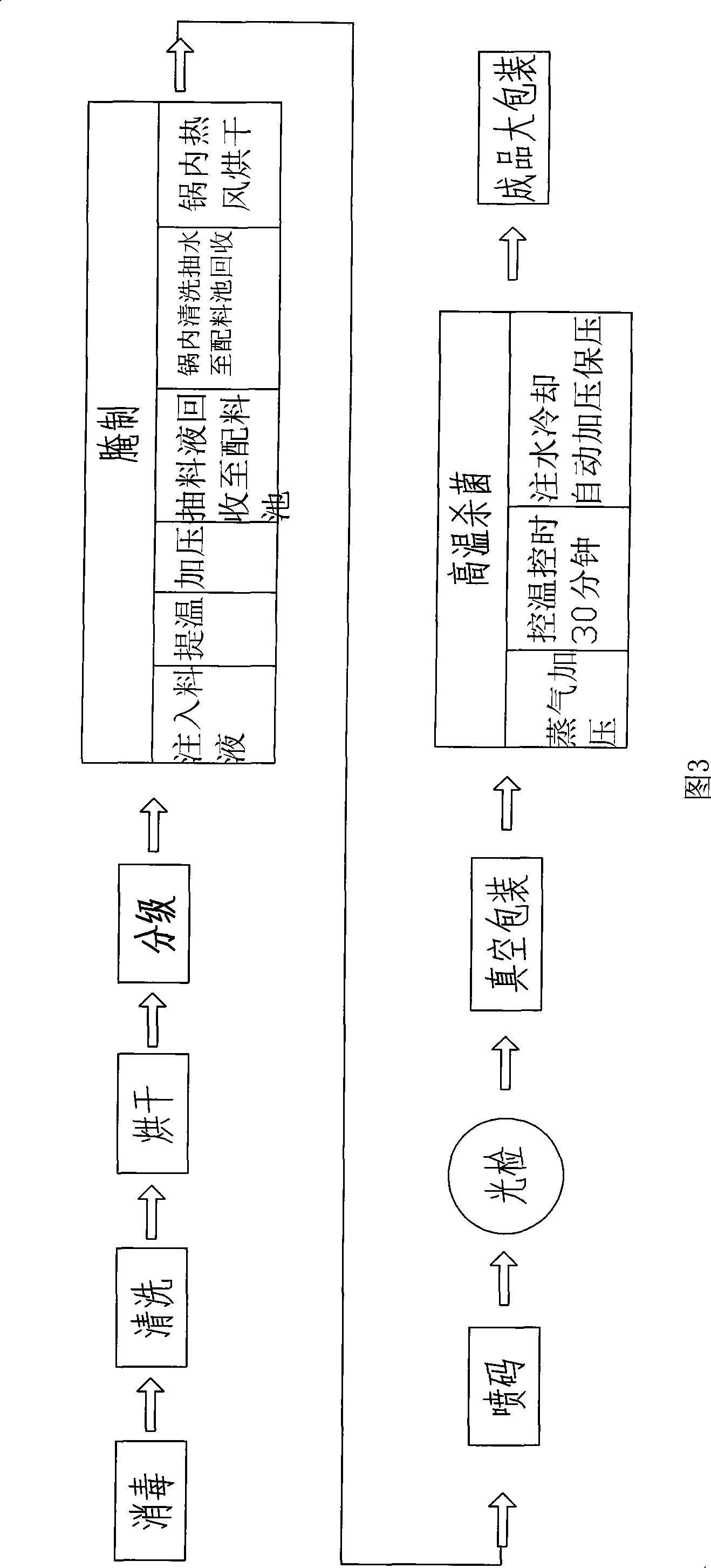

[0029] As shown in Figure 1-3, an environment-friendly fast salted egg pickling production device at least includes main machines such as a washing machine 2, a vacuum packaging machine 8, a pressure curing pot 5, and a high-temperature sterilization pot 9, wherein the disinfection tank 1. The cleaning machine 2 is connected to the classifier 4 through the drying part 3. The classifier 4 is connected to the material inlet and outlet of the pressure marinating pot 5 through the third conveying mechanism 12. The marinating pot 5 generally presents a horizontally horizontal tank body. The opening on one side becomes the material inlet and outlet, and a movable and open material cover for sealing is installed, so that the eggs in baskets can be stacked in the pot body. The upper part of the pressure marinating pot 5 is arranged with a water inlet p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com