Manufacturing method for semi-flexible printed circuit board

A technology of printed circuit boards and manufacturing methods, which is applied in the direction of printed circuit manufacturing, printed circuits, chemical instruments and methods, etc., can solve the problems of high difficulty in process control, complicated process flow, and low product reliability, and achieve cost reduction, The processing flow is simple, and the effect of improving the yield and reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0065] like Figure 1 to Figure 4 As shown, the manufacturing method (milling method) of the semi-flexible printed circuit board in the present preferred embodiment comprises the following steps:

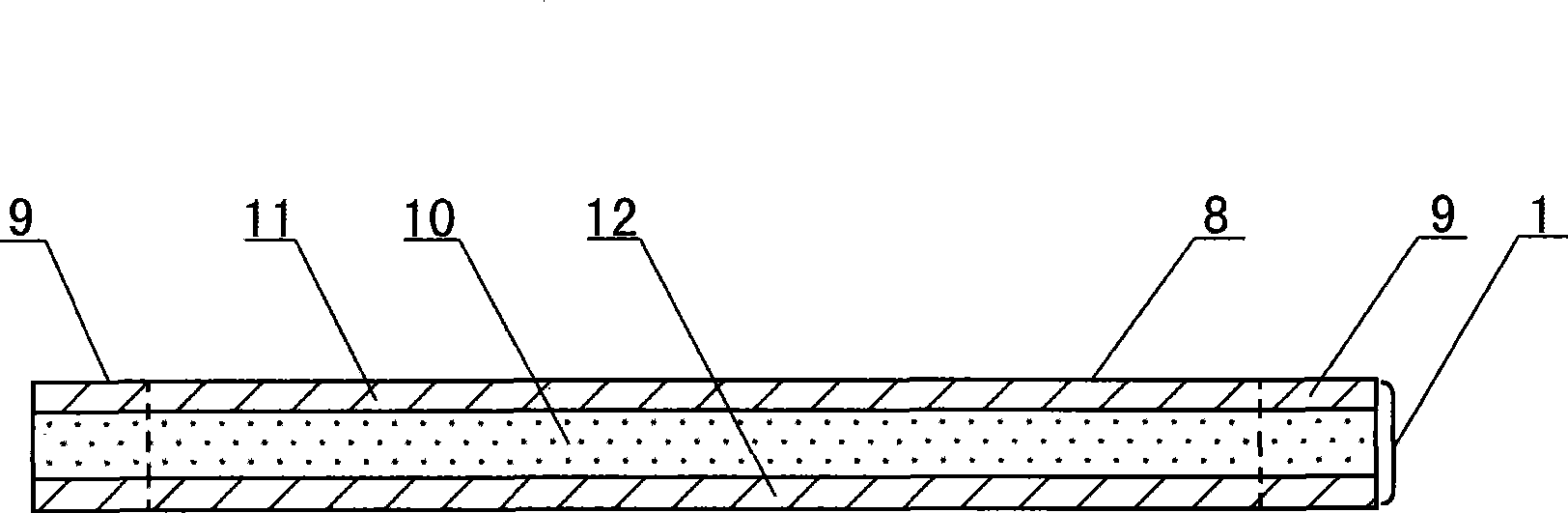

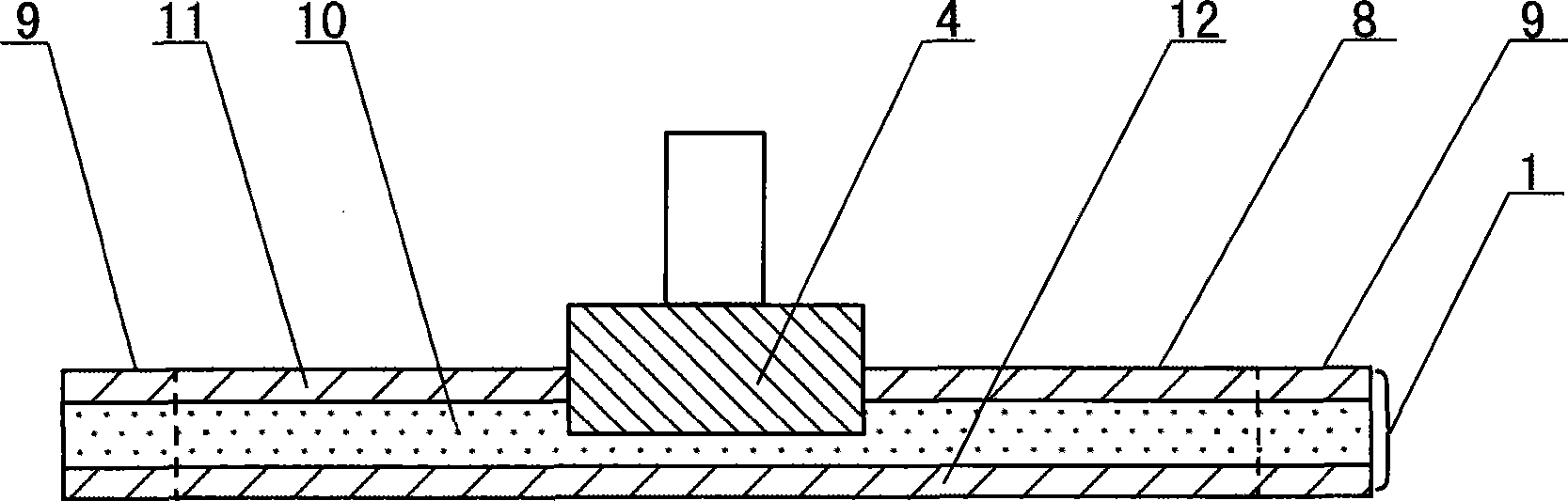

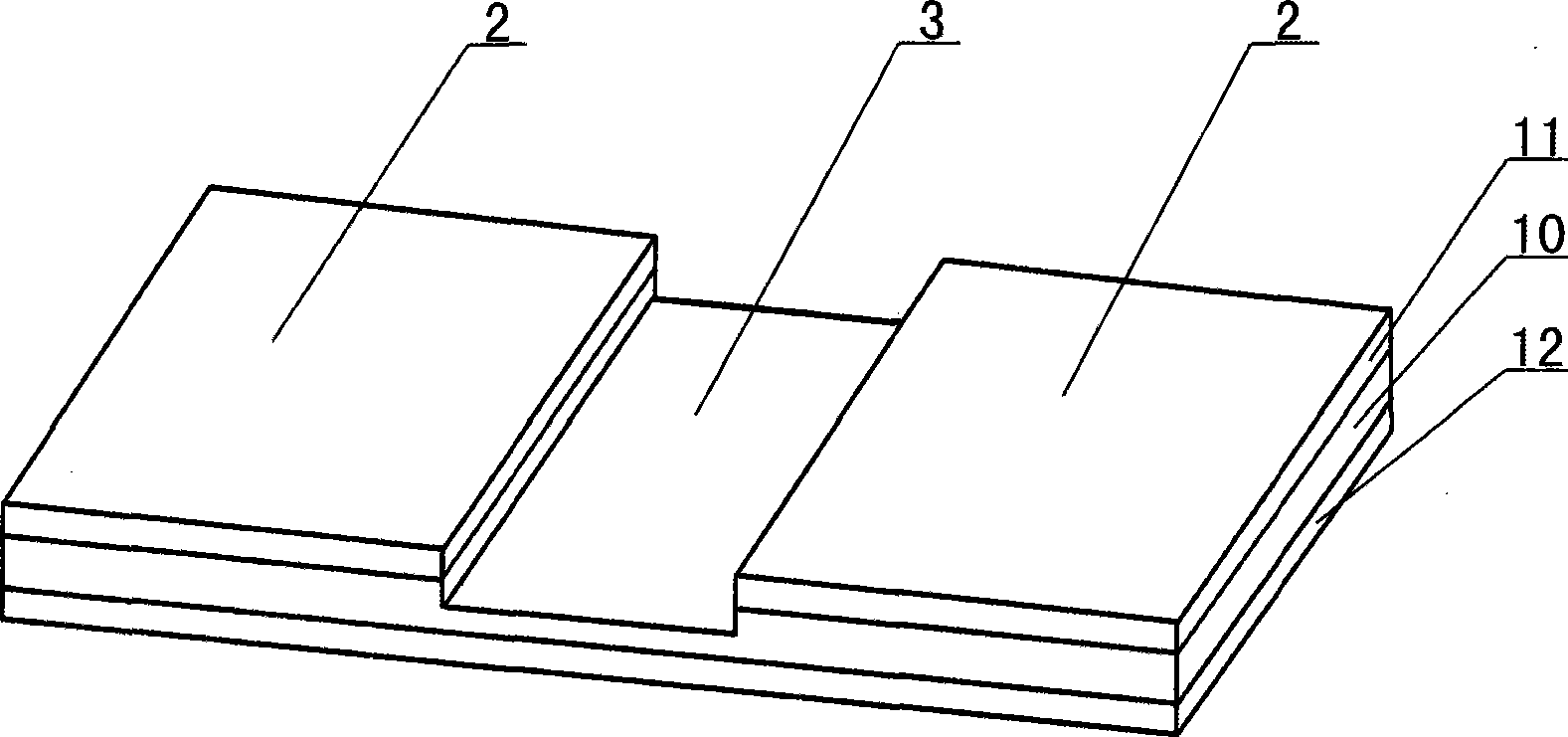

[0066] (1) Prepare the sheet material, which is the rigid base plate 1; if figure 1 As shown, the above-mentioned rigid bottom plate 1 adopts a glass cloth-epoxy resin copper-clad board, and the glass cloth-epoxy resin copper-clad board is a double-sided board, including an upper conductive layer 11, an intermediate insulating layer 10 and a lower conductive layer 12, The upper conductive layer 11 is pressed together with the lower conductive layer 12 through the intermediate insulating layer 10 . The above-mentioned upper and lower conductive layers 11, 12 are copper foil layers, and the above-mentioned intermediate insulating layer 10 is a resin layer.

[0067] (2) Divide the rigid base plate 1 into a forming area 8 (area within the dotted line) and an exterior area 9 (area outs...

Embodiment 2

[0073] like Figure 5 to Figure 8 As shown, the manufacturing method (milling method) of the semi-flexible printed circuit board in embodiment 2 comprises the following steps:

[0074] (1) prepare sheet material, this sheet material comprises rigid base plate 1, core plate 5 and prepreg 6, and above-mentioned core plate 5 is single-layer core plate 51; Figure 5 As shown, the above-mentioned rigid base plate 1 is the same as the rigid base plate 1 in Embodiment 1, and the above-mentioned single-layer core plate 51 is also basically the same as the rigid base plate 1 in Embodiment 1, but the name is different.

[0075] (2) Pre-dividing the rigid base plate 1, the core plate 5 and the prepreg 6 into a forming area 8 and an exterior area 9;

[0076] (3) In the molding area 8, the rigid base plate 1, the core plate 5 and the prepreg 6 are pre-divided into a flat plate area 2 and a flexible bending area 3;

[0077] (4-1) Perform graphic processing on the pressing surface of the r...

Embodiment 3

[0084] like Figure 9 to Figure 13 As shown, the manufacturing method (opening method) of the semi-flexible printed circuit board in embodiment 3 comprises the following steps:

[0085] (1) Prepare the sheet material, which includes a rigid base plate 1, a core plate 5 and a prepreg 7; the structure of the rigid base plate 1 is the same as that of the rigid base plate 1 in Implementation 1, and the above-mentioned core plate 5 adopts a two-layer core plate, and the core plate 5. The single-layer core board 51 and the single-layer core board 52 are pressed together by the prepreg 6 to form a multi-layer core board. Certainly, the above-mentioned core board 5 can also adopt a single-layer core board 51 or a multi-layer core board with more than two layers; the above-mentioned prepreg 7 adopts a low-fluidity prepreg (No FLOW);

[0086] (2) Pre-dividing the rigid base plate 1, the core plate 5 and the prepreg 7 into a forming area 8 and an exterior area 9;

[0087] (3) In the fo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com