Package and semiconductor device

A semiconductor and device technology, which is applied in the field of semiconductor devices, can solve the problems of increasing the number of steps, and achieve the effects of suppressing temperature rise, improving fixing strength, and suppressing unevenness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

[0052] The package to be described below is, for example, explained by employing a case where the package accommodates a UV-ray light emitting diode as a semiconductor element. Incidentally, in the present invention, not only UV-ray light-emitting diodes that emit light in the ultraviolet wavelength range are used, but light-emitting diodes other than UV-ray light-emitting diodes, such as light-emitting diodes that emit light in the visible wavelength range, can also be used to constitute the package. diode.

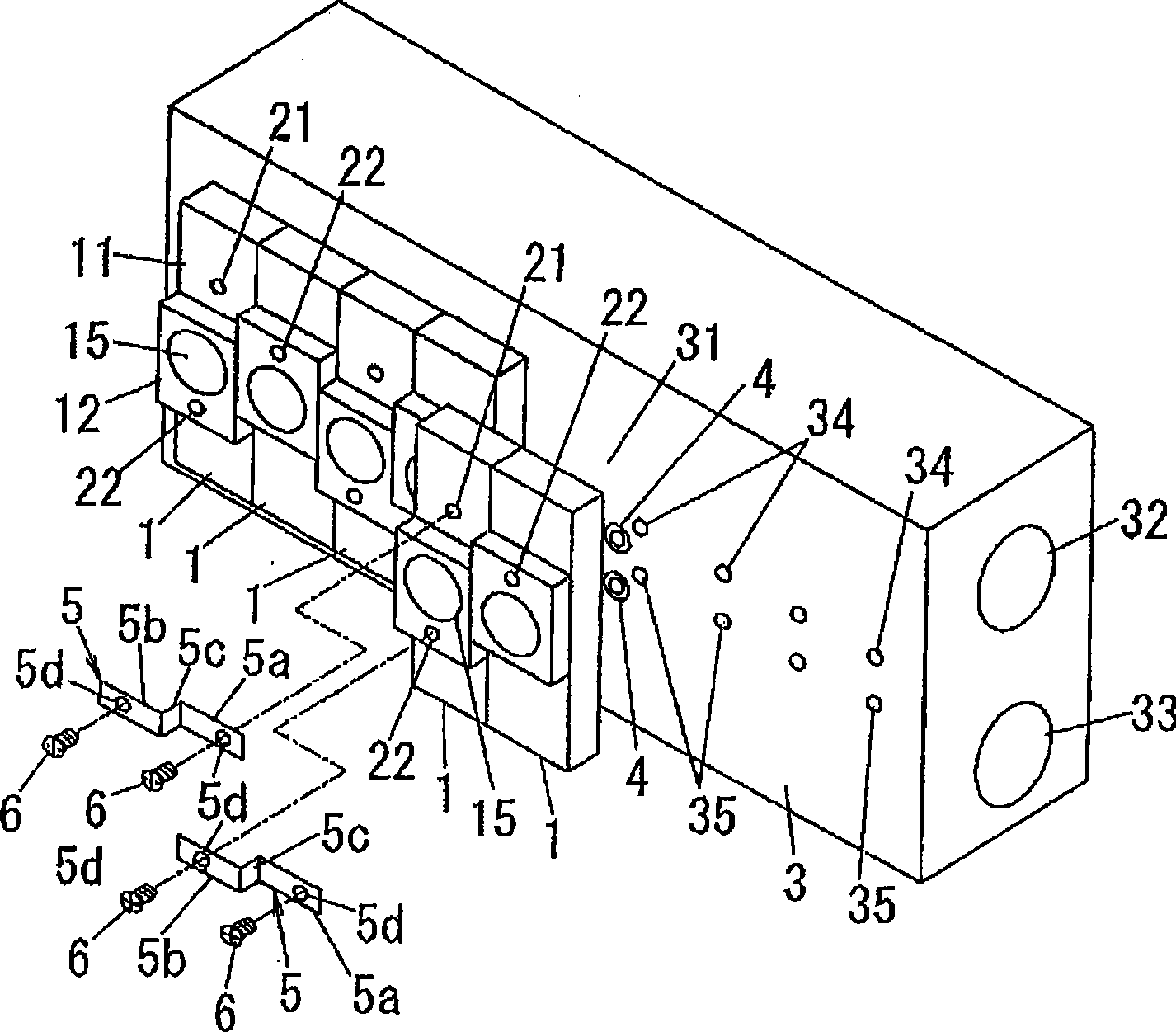

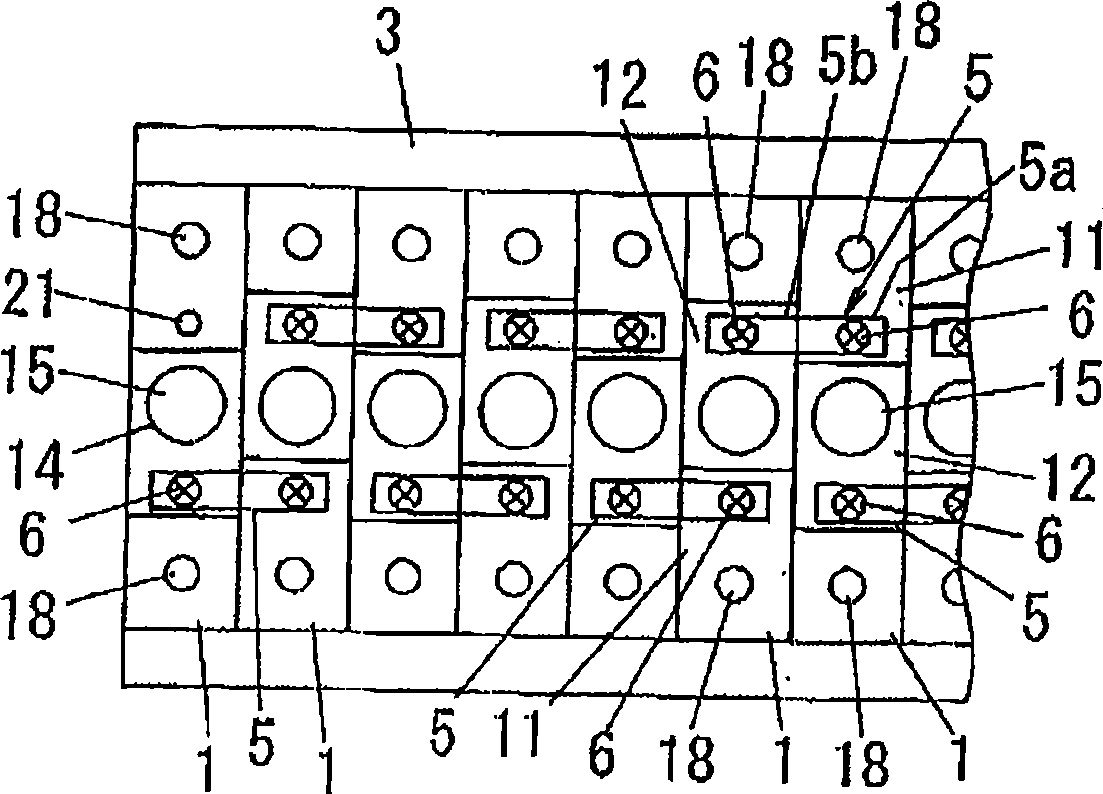

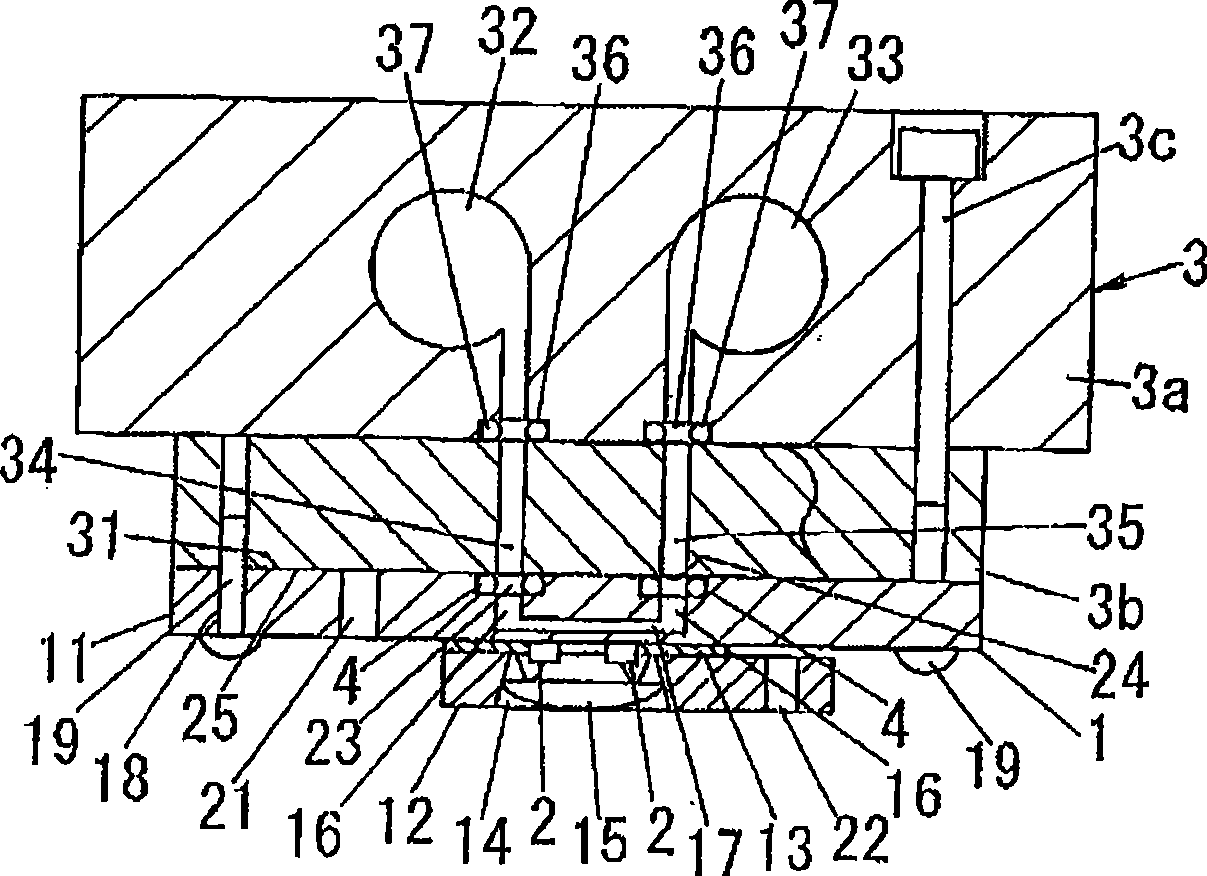

[0053] Such as Figures 3 to 5C As shown, the package 1 is constructed as a layered product produced by laminating a base substrate 11 made of a metal plate on which UV-ray light emitting diodes 2 are mounted, a cover substrate 12 and an insulating material layer 13, The cover substrate 12 is made of a metal plate surrounding the area of the base substrate 11 in which the UV-ray light emitting diodes 2 corresponding to bear chips are mounted, and the insulating materi...

no. 2 example

[0078] The first embodiment has provided an example in which the base substrate 11 and the cover substrate 12 are electrically connected to each other through the connection board 5 , which is a separate component from the package 1 . However, in the present embodiment, the cover substrate 12 and the base substrate 11 are connected together through the connection piece 7, which serves as a first connection conductor extending continuously and integrally from each cover substrate 12, instead of Figure 6 and Figure 7 Connection plate 5 shown. Specifically, the connection piece 7 extends away from the center of the base substrate 11 in the longitudinal direction thereof from one side surface at one end of the cover substrate 12 in the transverse direction of the base substrate 11 . In the present embodiment, the cover side connection hole 22 is not formed in the cover substrate 12 , and the through hole 7 a is formed at the end of the connection piece 7 .

[0079] In order to...

no. 3 example

[0084] In the above-described embodiments, in the longitudinal direction, the distances from the centerline of the base substrate 11 to the respective end edges of the cover substrate 12 along its transverse direction are different. In this example, if Figure 8A and 8B As shown, the centerline of the base substrate 11 along its transverse direction and the centerline of the cover substrate 12 along its transverse direction are positioned such that, in its longitudinal direction, the distances from the centerline of the base substrate 11 to the respective end edges of the cover substrate 12 are identical. On the other hand, in order to avoid covering the base-side connection hole 21 with the cover substrate 12 in this structure, a hole 26 is formed in the cover substrate 12 to expose the base-side connection hole 21 .

[0085]The hole 26 may be formed with a through hole having a diameter larger than the head of the connecting screw 6 so that the connecting screw 6 does not ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com