Supporting construction for upper layer tanks of double row tank magnesium reducing furnace

A supporting structure and reduction furnace technology, applied in furnaces, muffle furnaces, cooking furnaces, etc., can solve the problems of poor support masonry structure strength of the upper tank, large heat shielding of the reduction tank, uneven heating of materials in the tank, etc. Improve the temperature uniformity, improve the reduction output rate, and eliminate the effect of temperature dead angle in the furnace

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The embodiments of the present invention will be described in detail below in conjunction with the drawings, but the protection scope of the present invention is not limited by the embodiments.

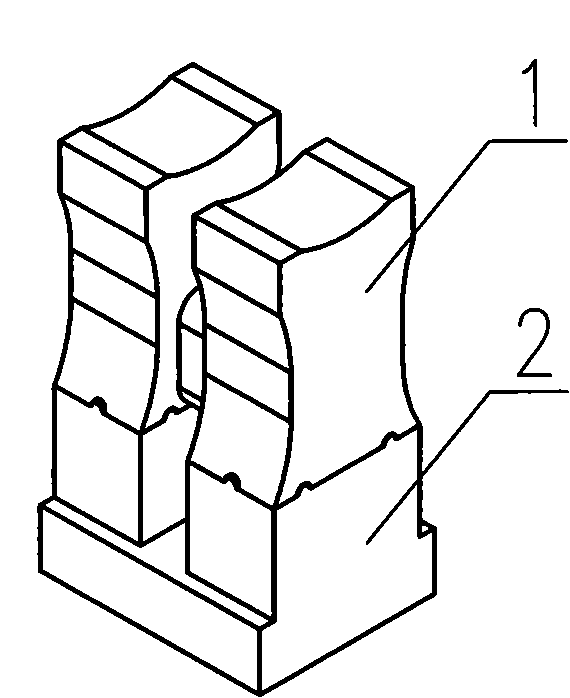

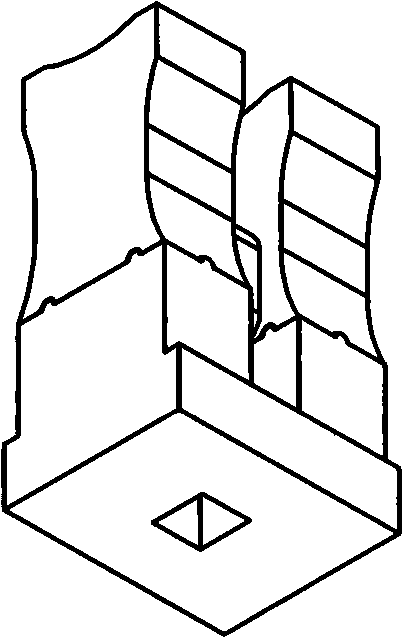

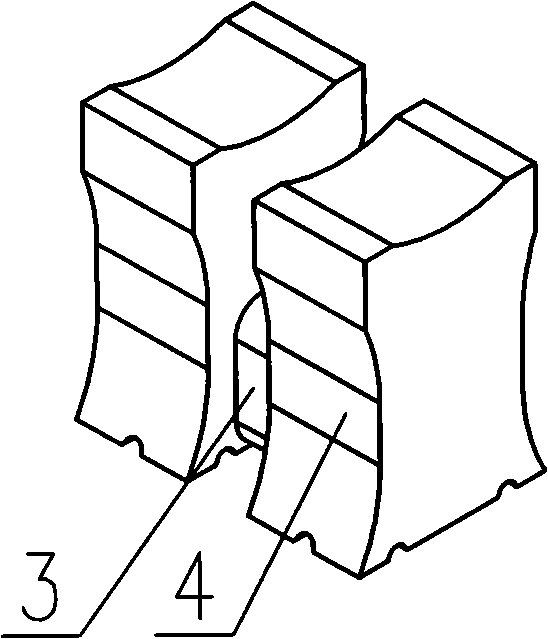

[0025] As shown in the figure, a supporting structure for the upper tank of a double-row tank magnesium reduction furnace is composed of an upper tank brick 1 and a lower base checker brick 2. The upper pot holding brick 1 is saddle-shaped, and the middle of the saddle-shaped upper pot holding brick 1 is provided with a reinforcing connecting rib 3. The cross section of the reinforcing connecting rib 3 is any one of ellipse, rectangle, circle or polygon. The side surface of the upper pot brick 1 is provided with a concave diversion surface 4, and the concave diversion surface 4 is any one of an arcuate curved surface, an isolated intersection surface, an obtuse intersection surface or a right angle intersection surface. The lattice brick 2 of the lower base is a twin type connect...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com