Large polygonal concrete group bin and building method thereof

A polygonal and concrete technology, which is applied in the direction of buildings, building types, and large-capacity bulk material storage, etc., can solve the problems of large amount of sliding form construction, large self-heavy warehouse panels, and extended construction period, so as to reduce weight and materials. The effect of consumption and material saving

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

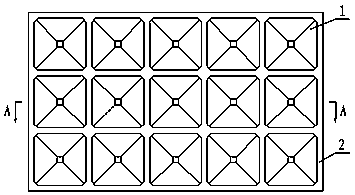

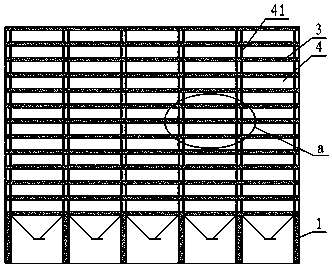

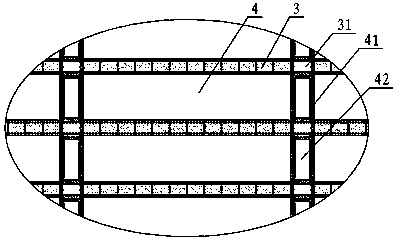

[0046]A large polygonal concrete group warehouse, which consists of: a warehouse bottom 1, a warehouse body 2 connected to the warehouse bottom, and the warehouse body 2 includes a group of cast-in-place transverse beams 3, and each of the cast-in-place A group of transverse slabs 4 are fixed on the pouring transverse beams 3, the transverse slabs are hollow slabs, and a group of longitudinal slabs 41 are interlacedly connected with the transverse slabs, the longitudinal slabs are hollow slabs, now The pouring longitudinal beam 31 is connected and fixed to the longitudinal slab 41 and the cast-in-place transverse beam 3, the transverse slab 4 is connected and fixed to the longitudinal slab 41 through the cast-in-place column 32, and the cast-in-place transverse beam 3 and cast-in-place longitudinal beams 31 are connected by cast-in-place columns 32 to form horizontal polygonal frame beams, and the multi-layer horizontal polygonal frame beams are connected by cast-in-place colum...

Embodiment 2

[0048] In the large polygonal concrete group warehouse described in Example 1, the hollow structure in the horizontal warehouse board 4 and the longitudinal warehouse board 41 is a group of weight-reducing cast-in-place chambers 42 that are vertically parallel to each other. The cross-section of the weight-reducing cast-in-place chamber is polygonal and circular, and the cross-sectional area of the weight-reduced cast-in-place chamber gradually increases from bottom to top, and there are ribs 43 between the described cast-in-place chambers.

Embodiment 3

[0050] In the large-scale polygonal concrete group warehouse described in embodiment 1 or 2, the full octagonal cast-in-place column is a rectangular cage formed by the transverse warehouse boards on both sides and the steel bars protruding from the longitudinal warehouse boards on both sides. After inserting vertical steel bars in the center, cast-in-place to form a full octagonal structure consisting of a protective transition surface connecting the horizontal slab and the longitudinal slab; the half-octagonal cast-in-place columns are horizontal slabs on both sides The steel bars protruding from the slab and the longitudinal slab on one side form a rectangular cage, and the vertical steel bars are inserted into the rectangular cage and then cast in place to form a protective transition surface connecting the horizontal slab and the longitudinal slab, Form a semi-octagonal structure.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Horizontal width | aaaaa | aaaaa |

| Height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com