Method of pulling up silicon single crystal

A single crystal silicon, crystallization technology, applied in the direction of self-melt pulling method, single crystal growth, single crystal growth, etc., can solve the problems of increased dislocation density, difficulty in eliminating dislocations, and large temperature gradient on the outer surface of the neck. , to achieve the effect of suppressing the change rate of the neck diameter, realizing the loss of production time, and realizing the shortening

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1~6

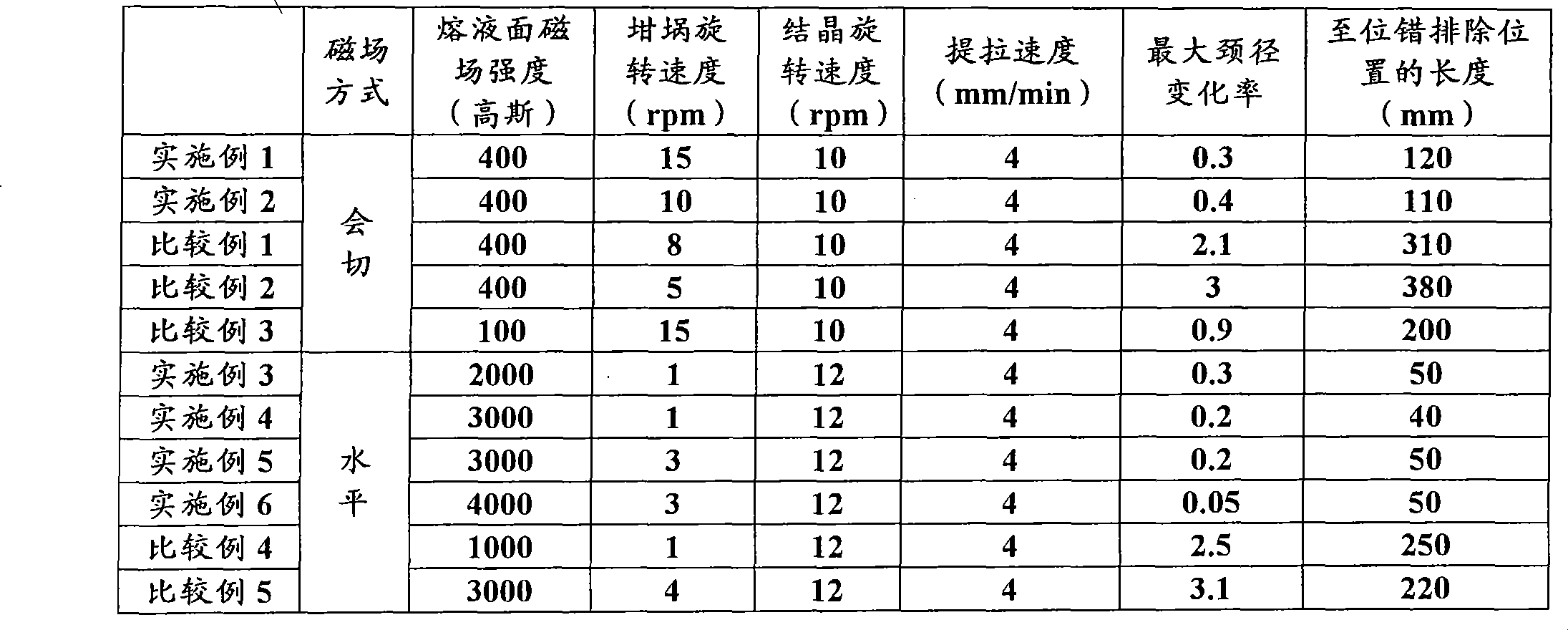

[0043] [Examples 1-6, Comparative Examples 1-5]

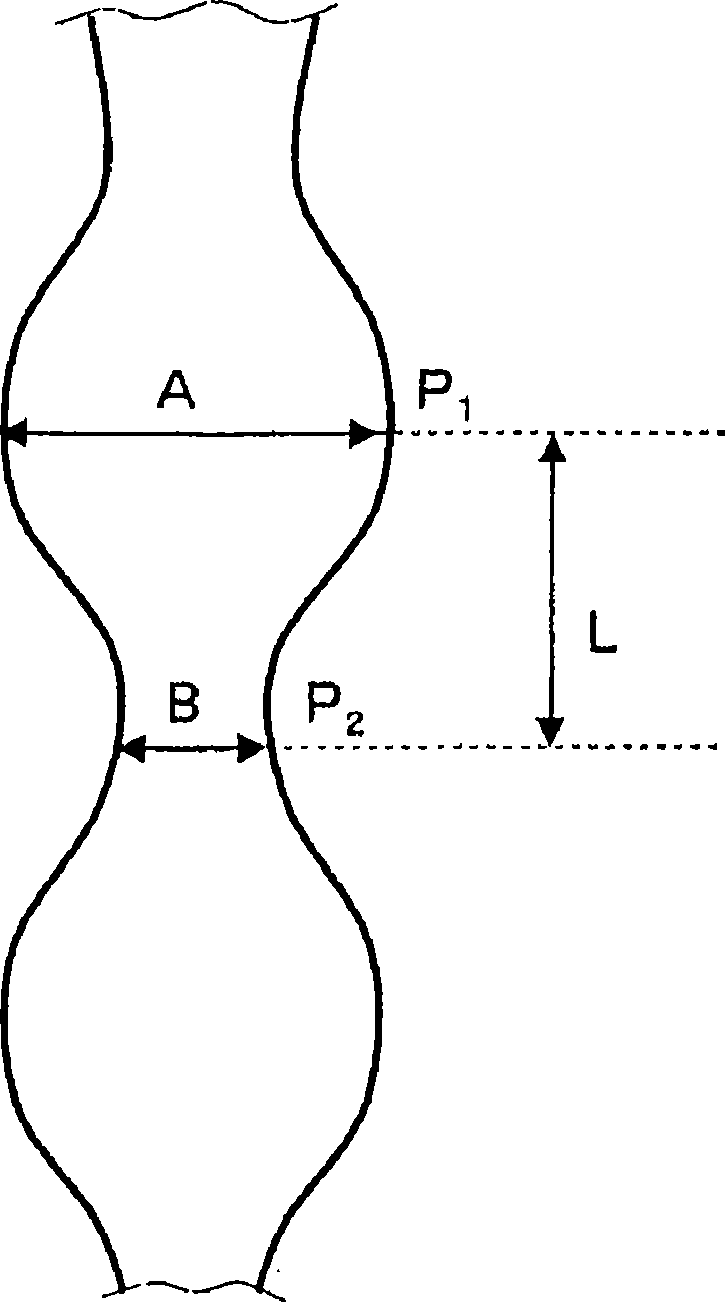

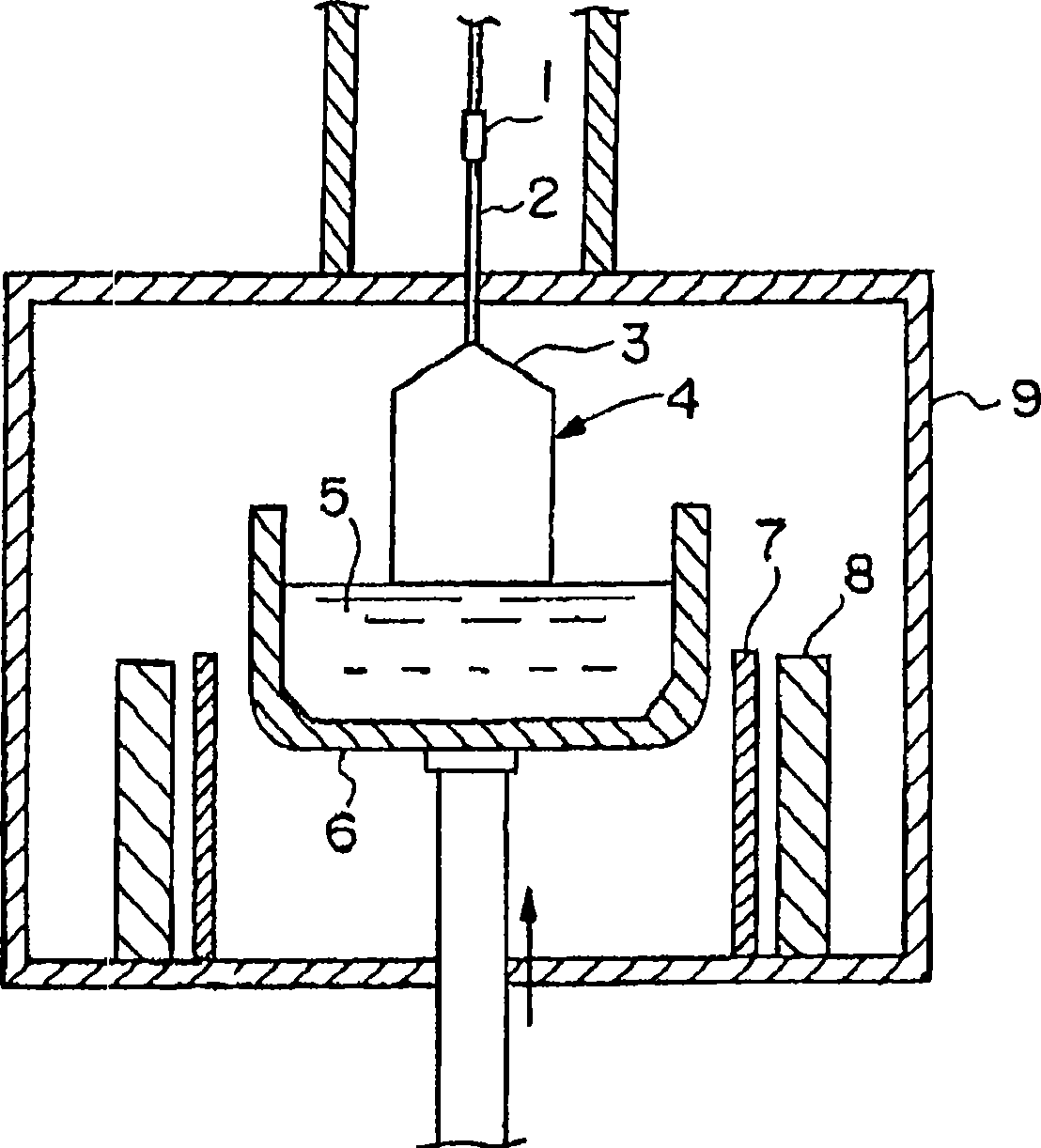

[0044] In a quartz crucible with a diameter of 24 inches, 100 kg of raw silicon melt was filled, and a single crystal pulling device was used to grow the neck so that the average neck diameter was 4.5 mm, and then a single crystal silicon was grown.

[0045] During neck growth, the conditions were the magnetic field application, crucible rotation speed, crystal rotation speed, and single crystal pulling speed as shown in Examples 1 to 6 and Comparative Examples 1 to 5 in Table 1, respectively.

[0046] The maximum neck diameter change rate and the length from the growth start position to the position after dislocation removal were measured respectively.

[0047] A summary of these results is shown in Table 1.

[0048] In addition, the measured value of the magnetic field strength is a measured value of the crucible wall surface in the case of a tangent magnetic field, and a measured value of the center in the case of a horizon...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com