Accessories mill-head bank

A technology of milling head and accessories, which is applied in the direction of metal processing machinery parts, clamping, support, etc., can solve the problems of low production efficiency, and achieve the effects of low design and manufacturing costs, simple program setting, and less design workload

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

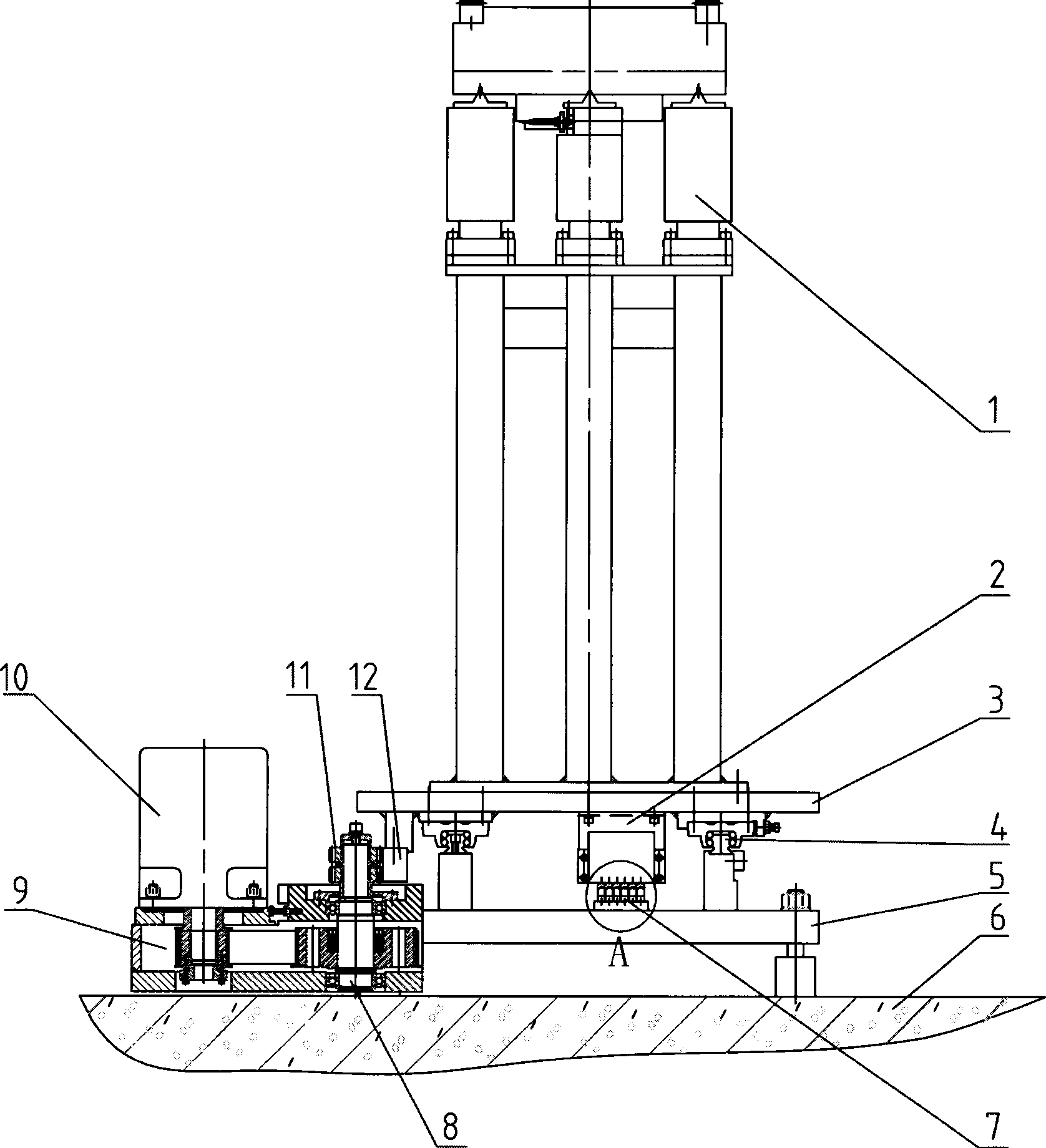

[0020] Refer to the manual attached figure 1 To 5, the accessory milling head library of this embodiment includes four accessory milling heads 1, and also includes a support 5 fixed on the foundation and a guide rail pair 4 on the upper part of the support for carrying the accessory milling head. head slide 3; and

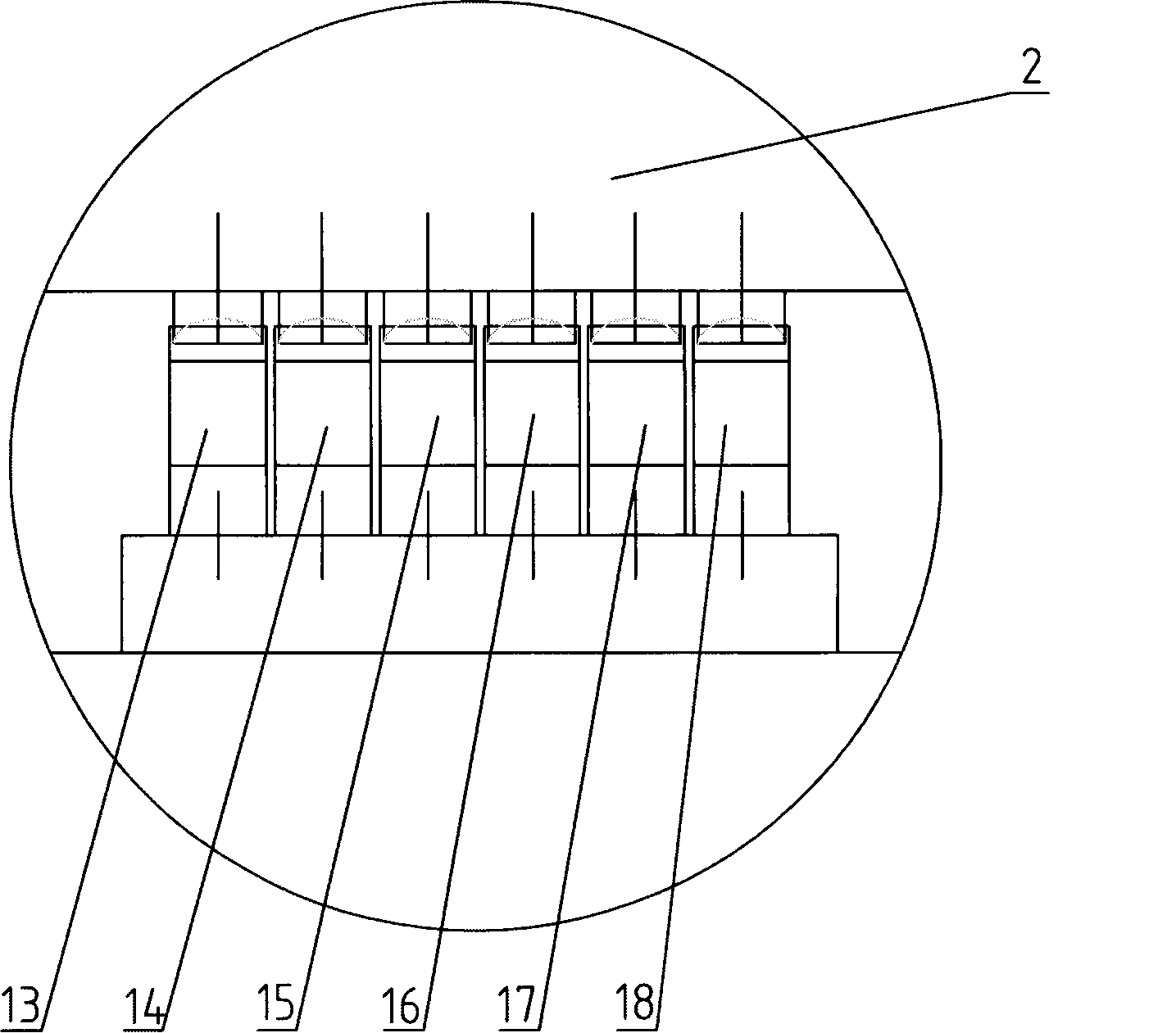

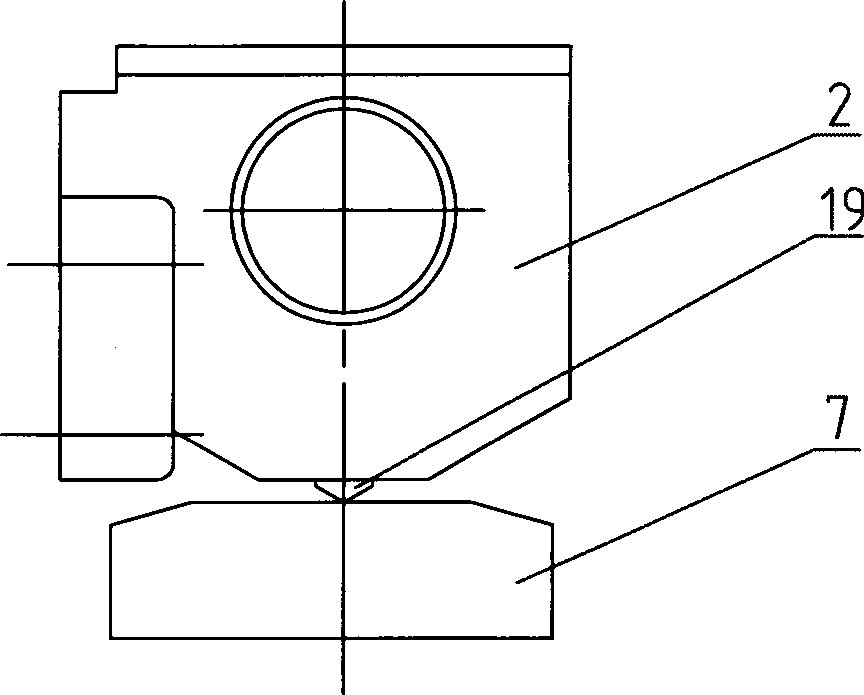

[0021] A combination switch 2 is arranged on the lower side of the tail of the sliding table, its switches are evenly distributed horizontally, and the guide rod 19 is downward; and

[0022] The bracket 7 is arranged on the upper side of the support for triggering the combination switch, and includes the attachment milling head brackets 14 , 15 , 16 , 17 distributed in the longitudinal direction corresponding to the number of the attachment milling heads. Corresponding to the distance between the attachment milling heads and one-to-one correspondence with the switches, when the attachment milling head runs to the replacement position, the corresponding switch just...

Embodiment 2

[0028] Compared with Embodiment 1, this embodiment is mainly different in the selection of the mechanical transmission device. The mechanical transmission device includes a rack 12 arranged under the sliding table 3, and an output shaft gear and the The gear box is meshed with the rack, the input shaft of the gear box is connected to the motor 10, and the gear box is used as an intermediate reduction transmission device, which is convenient for installation.

[0029] For the selection of the number of switches for the switch and the combination switch, the main consideration is the number of attachment milling heads.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com