Indoor wiring optical cable

An indoor wiring and optical cable technology, applied in the direction of fiber mechanical structure, etc., can solve the problems of easy breakage of optical fiber, interruption of information transmission, small cross-sectional size, etc., and achieve the effect of convenient installation and laying, large transmission information capacity, and small bending radius

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

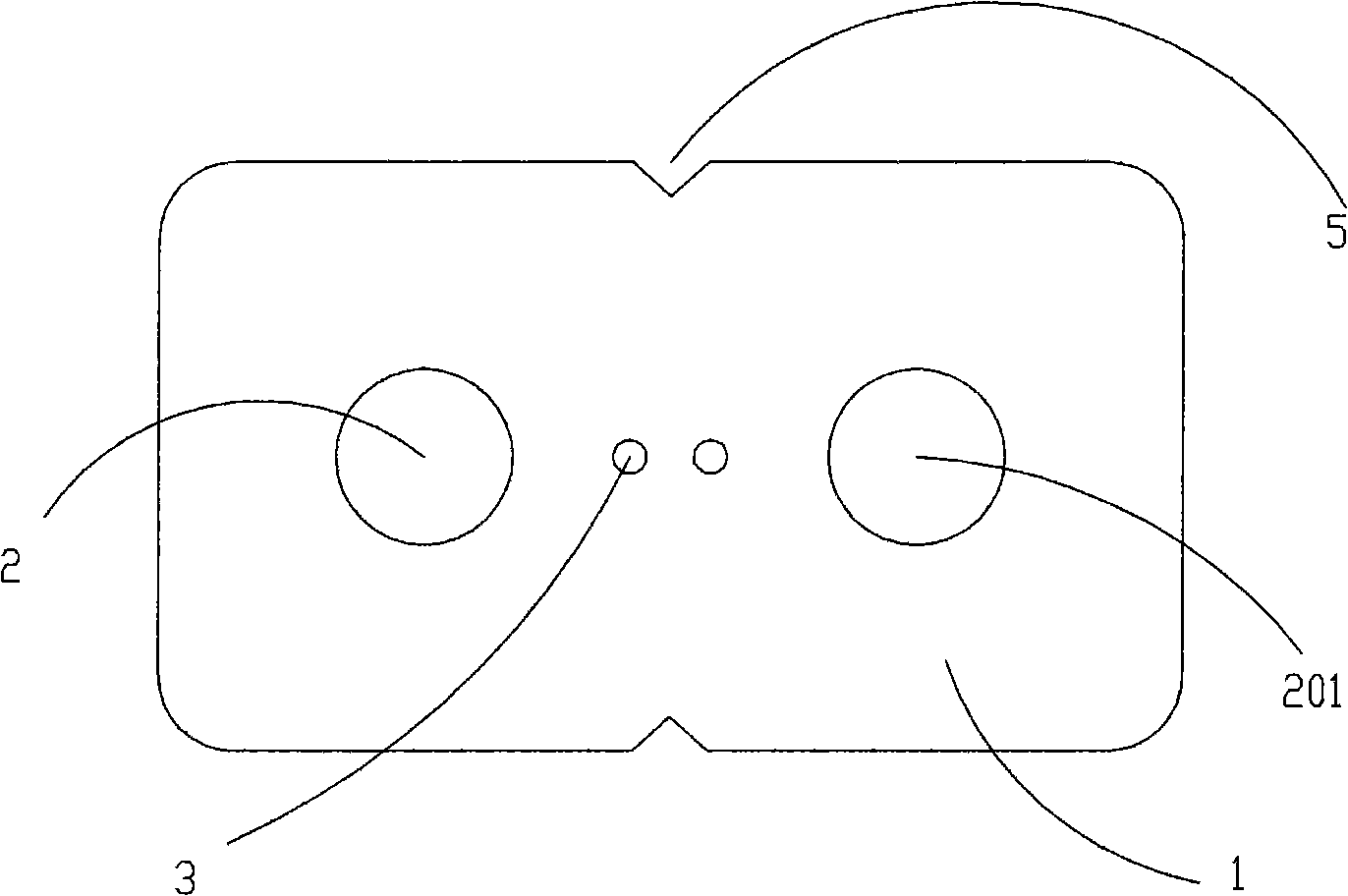

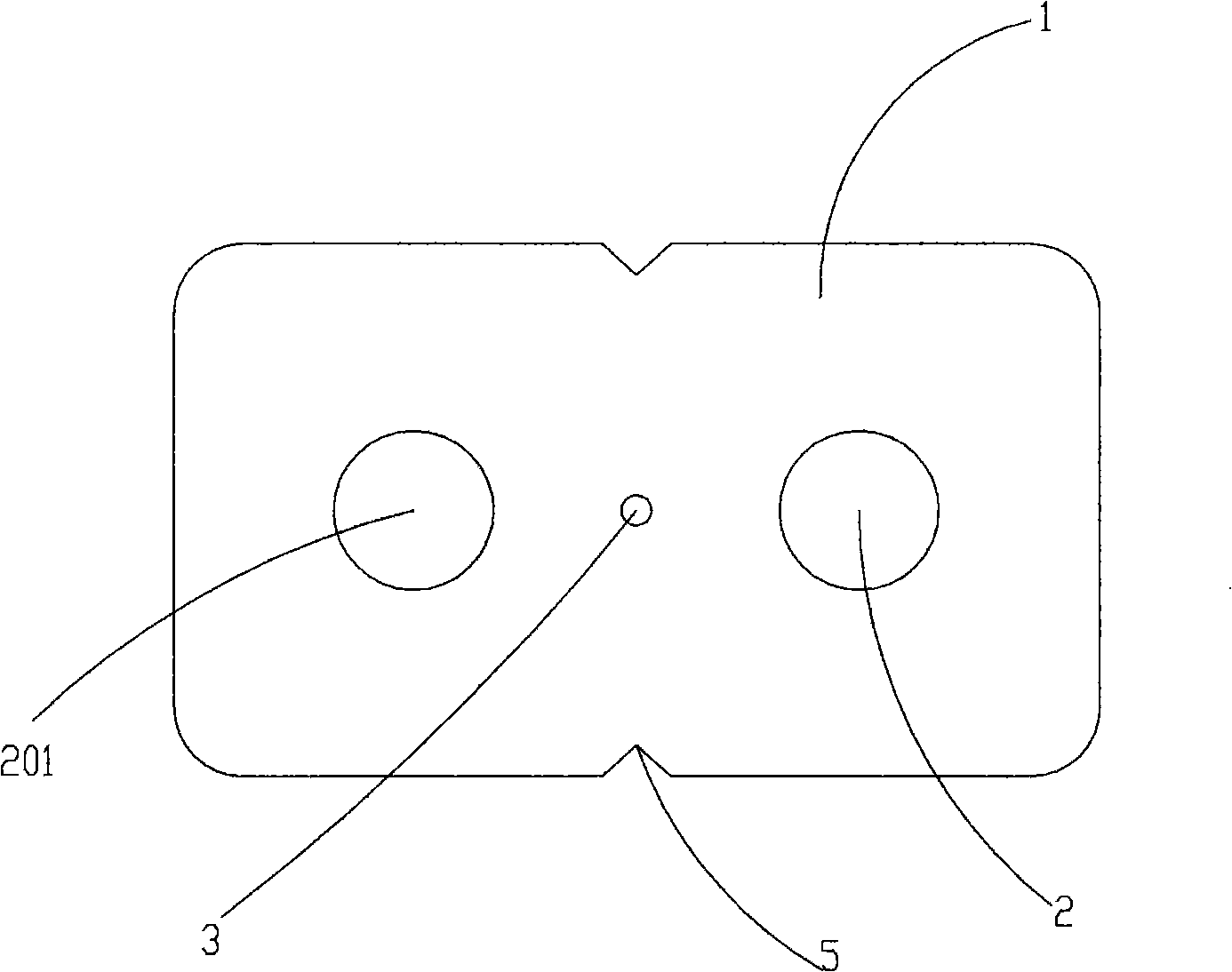

[0015] The special anti-stretch and anti-bending indoor wiring optical cable of the present invention is a small-sized (size 2×3MM) communication optical cable suitable for FTTH terminal wiring, and it is especially suitable for indoor wiring in buildings, hotels, offices, etc. As shown in the figure, it includes: 1. a sheathed cable body, 2. a strengthening member, 201, a strengthening core, 3. an optical fiber, 4. a groove, and 5. an opening.

[0016] The reinforcing member 2 is two reinforcing cores 201 integrated in the sheath cable body 1. The reinforcing cores 201 are made of aramid fiber material with high elasticity and a large coefficient of tension. The specific technical process is (as shown in Figure 4 Shown): Aramid fiber tow 901 is used as the matrix to be impregnated with UV ultraviolet light curing liquid, 902, and then enters the mold hole of forming mold 903 to be extruded and stretched and formed into a rod-shaped matrix of 0.5 mm by UV ultraviolet light curi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com