Renewable devulcanizing technological process and use thereof

A process method and reboiler technology, applied in the field of renewable desulfurization, can solve the problems of increased consumption, energy waste, large cooling water circulation, etc., and achieve the effect of reducing water consumption and reducing heat pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

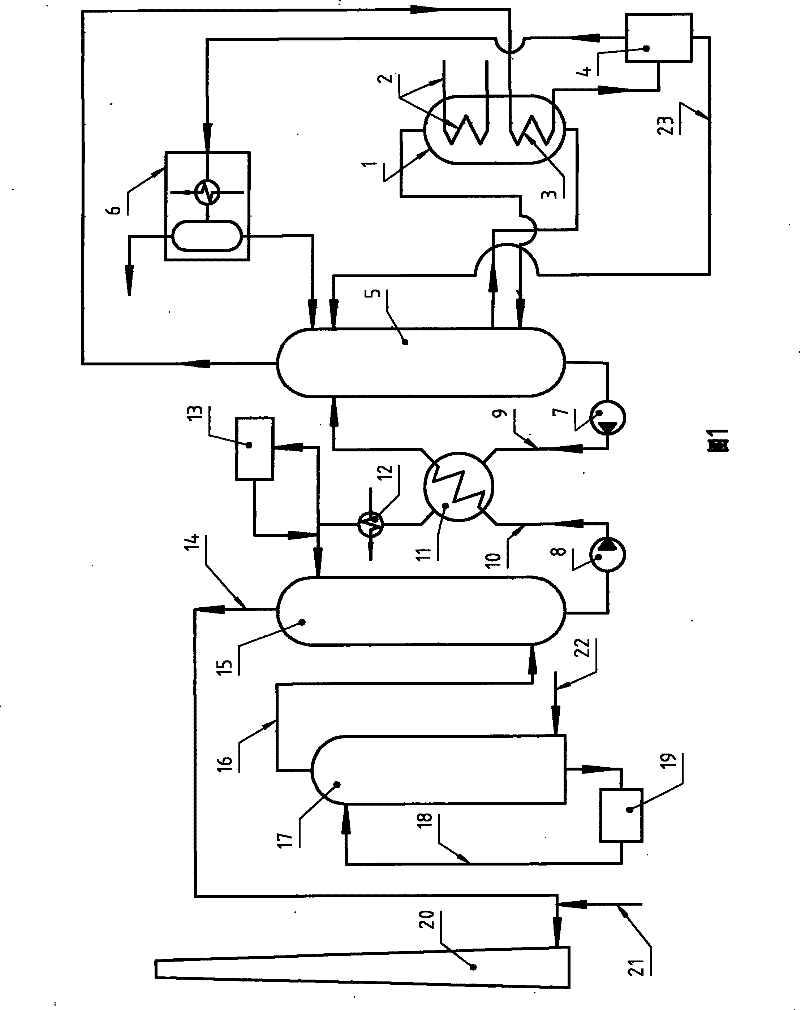

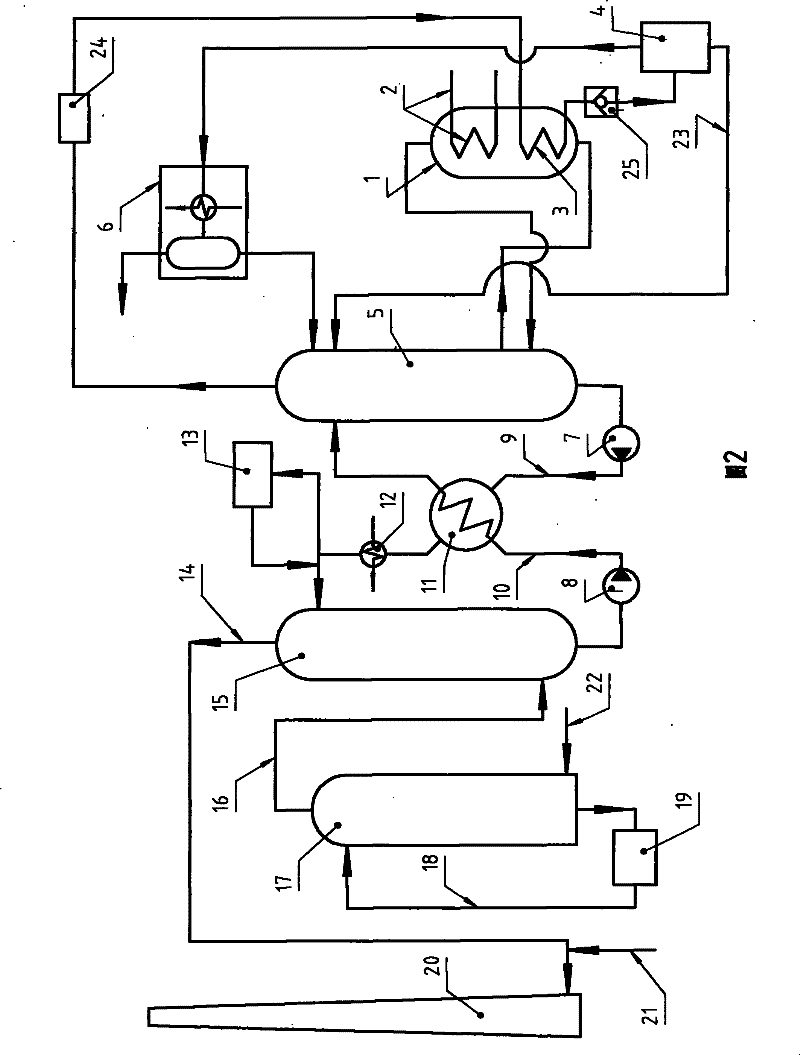

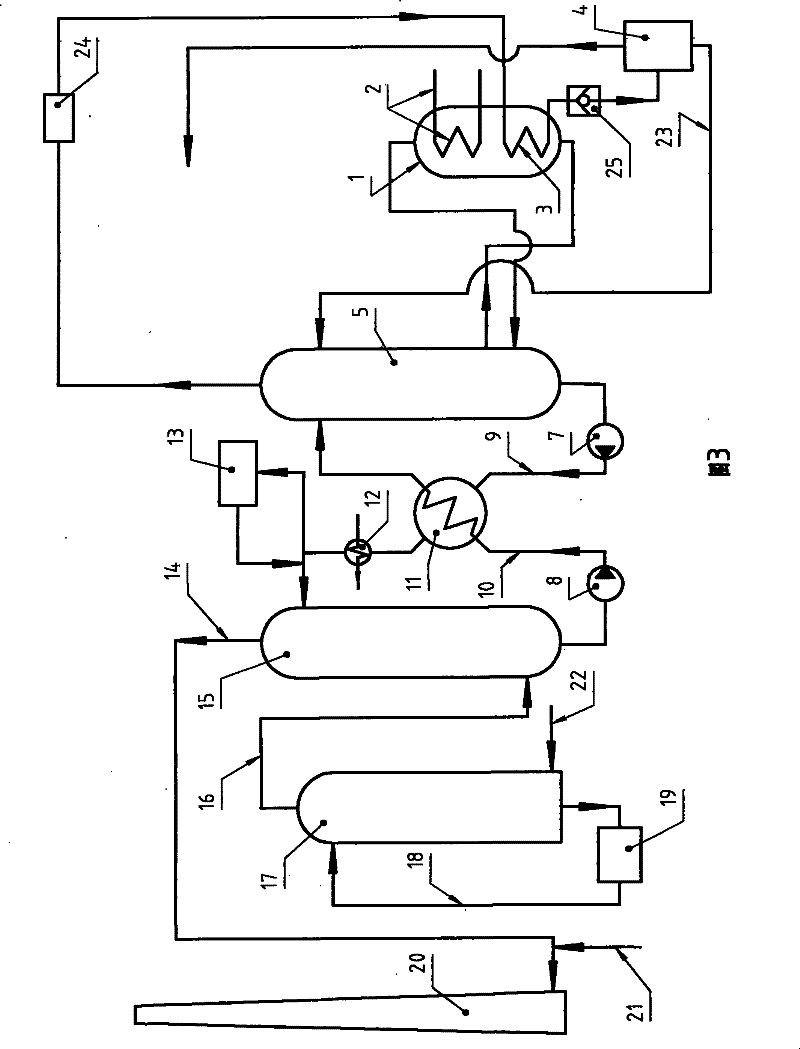

[0026] The specific implementation manners of the present invention can be described through examples and accompanying drawings.

[0027] attached in the manual figure 1 In the shown embodiment 1, 1 is a reboiler, 2 is a pipeline and a heat exchanger for external heating medium, and the external heating medium is usually low-pressure steam, and 3 is discharged from the desorption tower and has a higher temperature. Heat exchanger for mixed steam, 4 is steam-water separator, 5 is desorption tower, 6 is SO 2 7 is the amine liquid delivery pump after desorption, 8 is the amine liquid delivery pump to be desorbed, 9 is the amine liquid delivery pipeline after desorption, 10 is the amine liquid delivery pipeline to be desorbed, and 11 is a heat exchanger. 12 is a heat exchanger for further cooling of the desorbed amine liquid, 13 is an amine purification device, 14 is an emptying channel for flue gas after desulfurization, 15 is an absorption tower, and 16 is a cooling and remova...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com